Tridrive spherical robot

A spherical robot, three-drive technology, applied in the direction of motor vehicles, transportation and packaging, etc., can solve the problems of complex structure, not compact enough, etc., and achieve the effect of compact transmission mechanism, simplified structure and flexible transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

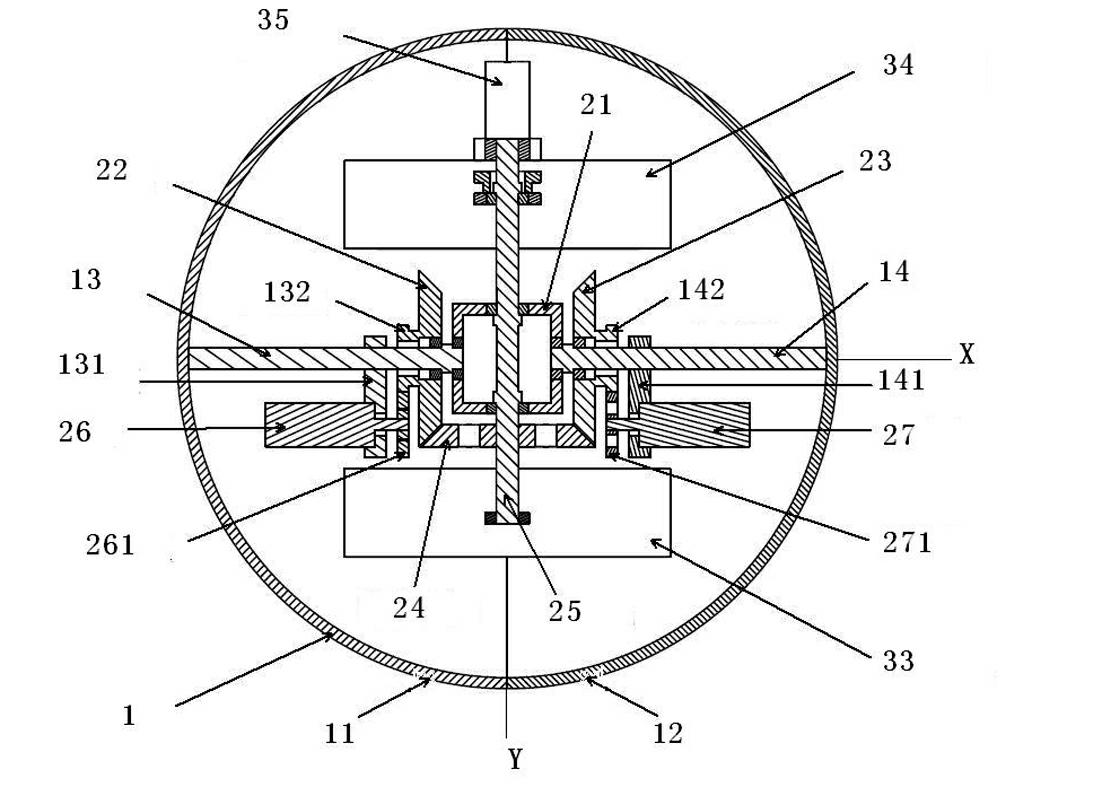

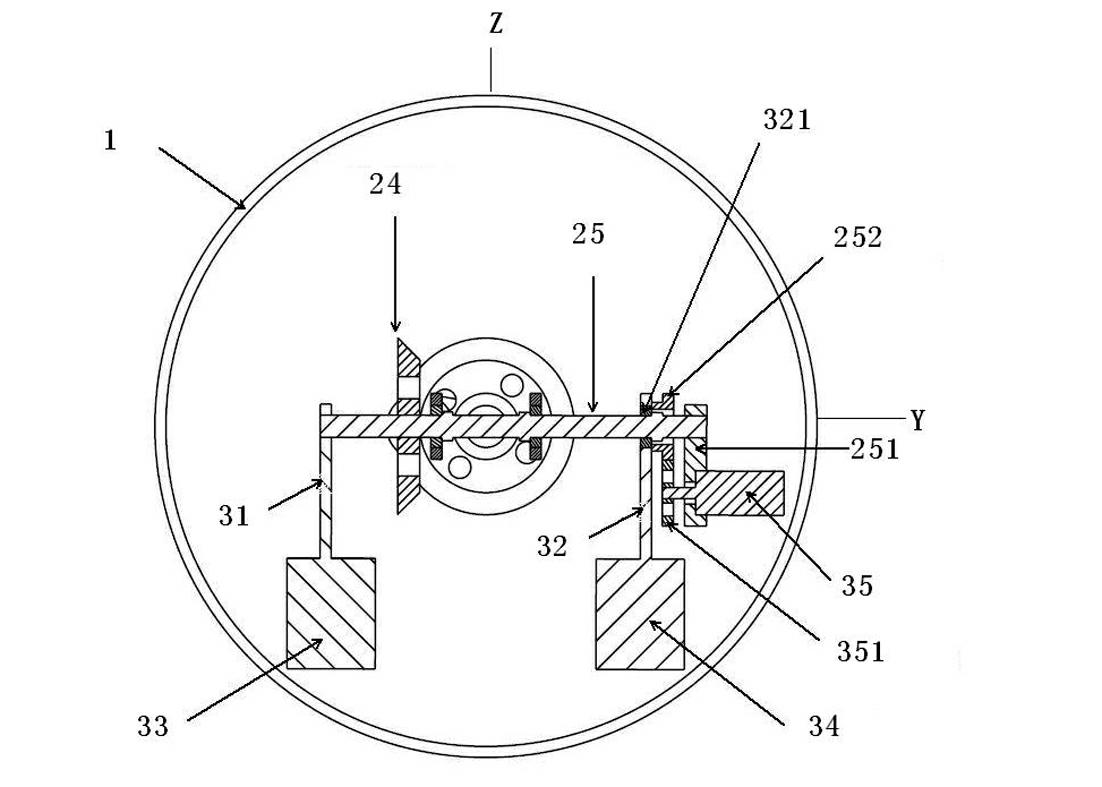

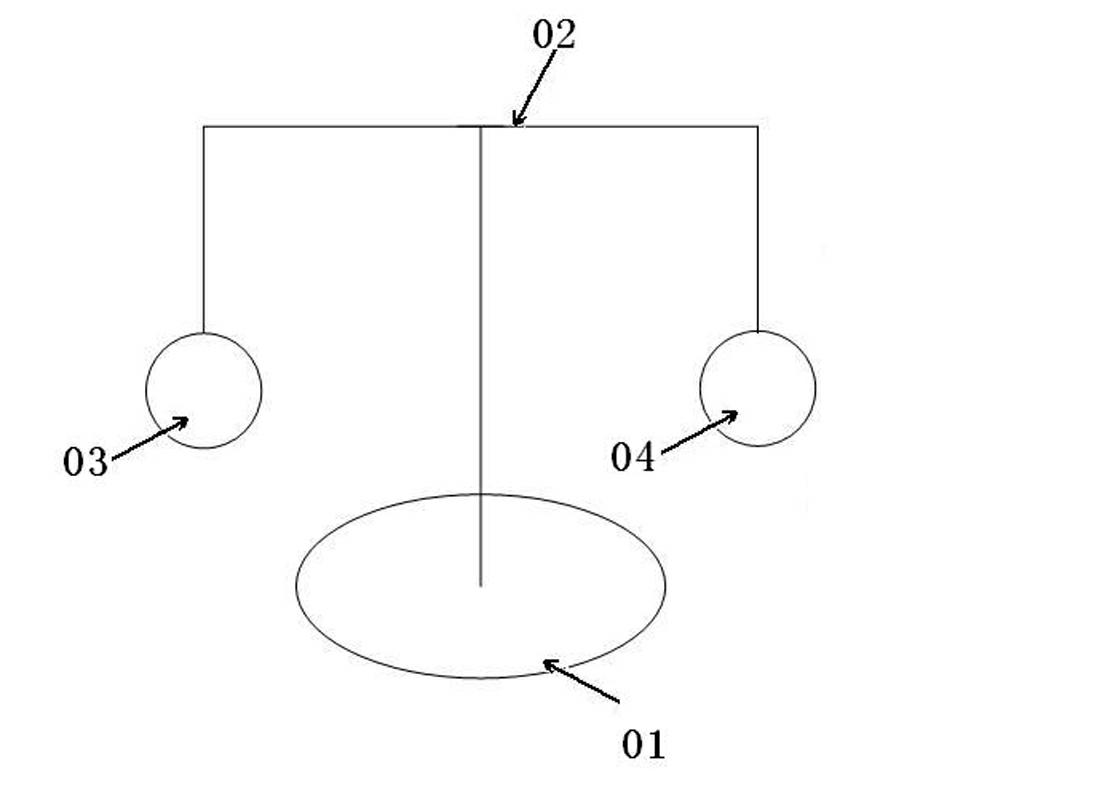

[0026] Such as figure 1 and figure 2 As shown, the three-drive spherical robot provided by the present invention includes a spherical shell 1, a differential transmission mechanism and its driving motor 2 and a counterweight device 3;

[0027] The spherical shell 1 is composed of two equal-sized hemispherical shells 11 and 12 fixedly connected. In the spherical shell 1, one of the axes passing through the center of the sphere, such as figure 1 and figure 2 In the shown example, the transmission shaft 13 and the transmission shaft 14 are arranged symmetrically in the X-axis direction on the horizontal plane, one end of the transmission shaft 13 is integrally connected with the hemispherical shell 11, and the transmission shaft 14 is integrally connected with the hemispherical shell 12. , the axes of the two transmission shafts are perpendicular to the bisecting line of the two hemispherical shells.

[0028] In the differential transmission mechanism, it includes a frame 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com