Centrifuge with a self-emptying centrifuge drum

A centrifuge and centrifugal technology, applied to centrifuges with rotating drums, centrifuges, etc., can solve the problems of increased cost, best emptying performance, and failure to realize the opening stroke of piston sliders. Achieving height reduction and optimizing emptying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

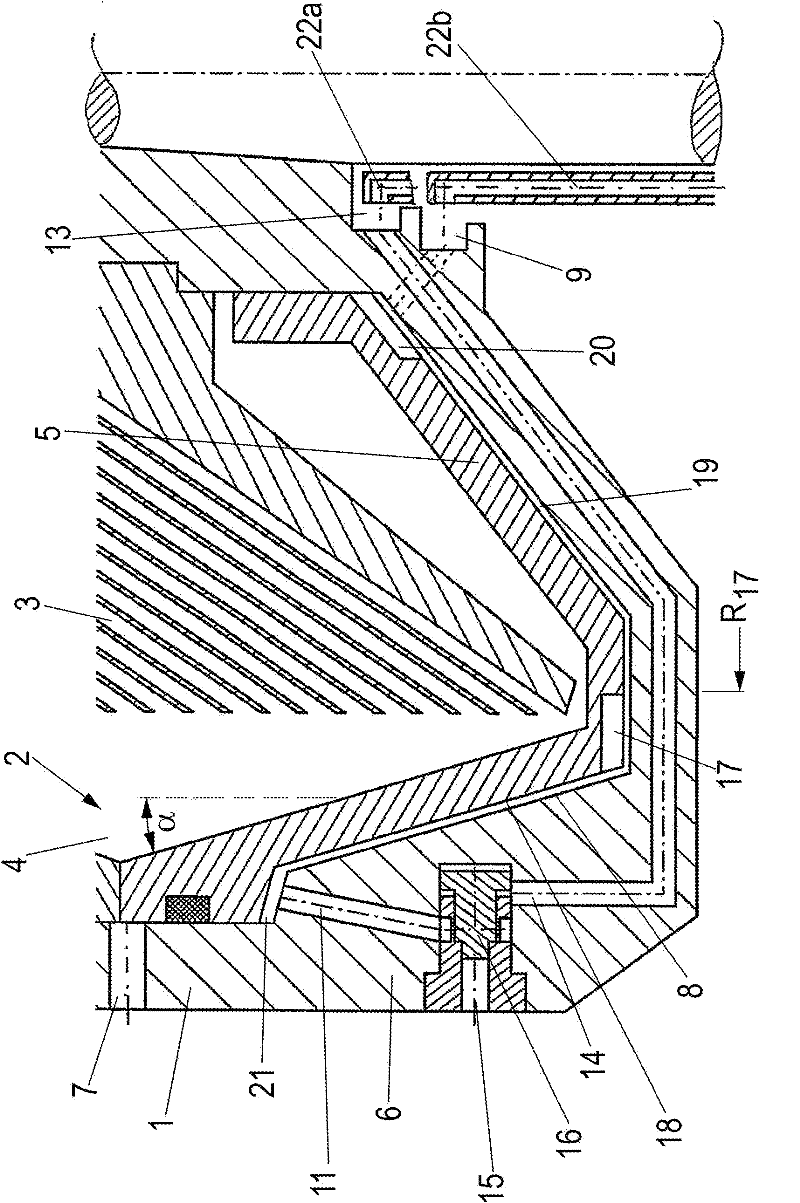

[0014] The centrifuged material (solid-liquid mixture) to be treated passes through the central inlet 22 (see in this regard Figure 4 configuration shown schematically) is conveyed to a rotatable drum 1 of a (dish) separator with a vertical axis of rotation, which has a centrifuge space 2 which is divided into a separation space 3 and a solid material space 4 .

[0015] The solid material space 4 is delimited on one side (here downwards) by an axially displaceable piston slide 5 which, during its axial movement, opens or closes the Throwing opening 7 for solid material.

[0016] Between the piston slide 5 and the drum shell 6 or the lower part of the drum, a closed cavity 8 into which a closed fluid can be input is constructed.

[0017] Via the injection chamber 9 and the supply line 10 , the closure liquid can be introduced into the closure chamber 8 . This closed liquid can be discharged from the drum 1 through one or more discharge lines 11, in which one or more piston v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com