Multi-planting arm transplanting mechanism with modified elliptical gear

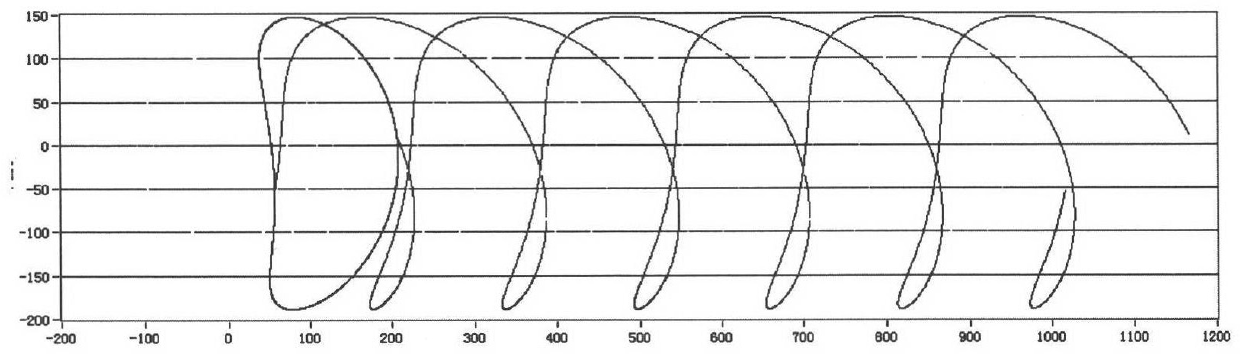

A technology of changing ellipse and planting arm, applied in the direction of transplanting machinery, belt/chain/gear, planting method, etc., can solve the problems such as the inability to meet the requirements of planting spacing, the quality of transplanting and the small spacing of transplanting, so as to ensure the quality of rice transplanting. , The effect of improving the trajectory of the seedling needle and reducing the speed of the seedling line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

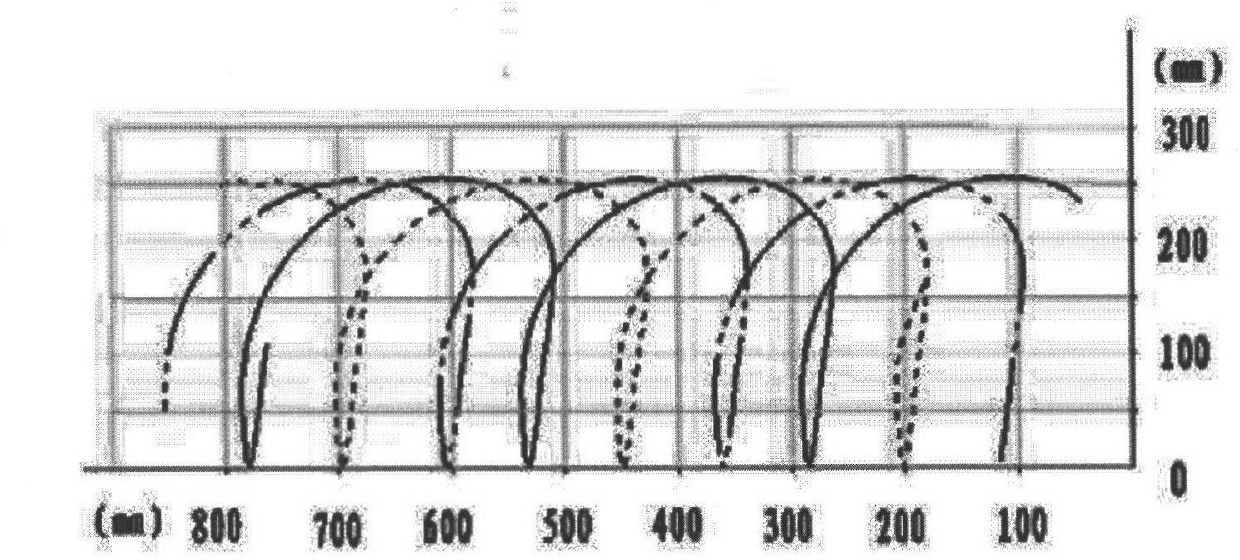

[0039] The modified elliptical gear multi-planting arm insertion mechanism of this embodiment is as follows: Figure 9 to Figure 11 As shown, the sprocket transmission box 1 supports the central shaft 6 protruding from both sides of the transmission box at both ends through the left and right flanges, and the central shaft is fixedly connected with the central sprocket 3 driven by the chain 2 . The two ends of the central shaft 6 are fixedly connected with the left and right revolving boxes 4 respectively. The central gear 5 inside the rotary box 4 is a denatured elliptical gear, which is vacantly sleeved on the central shaft, and forms a tooth-embedded fixed connection structure with the transmission box 1 through its end face teeth. Therefore, when the central shaft drives the rotary box to rotate, the center The gears are stationary. The sun gear 5 in this embodiment meshes with three planetary gears 8 uniformly distributed along the circumference through three idler gears...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com