Alfalfa layering parting harvester and harvesting method

A harvester and alfalfa technology, which is applied to harvesters, agricultural machinery and implements, cutters, etc., can solve the problems of increased carotene loss, expensive equipment, and large losses, so that it is not easy to be corrupted and deteriorated, and the difficulty of preparation is reduced. Effect of floret loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

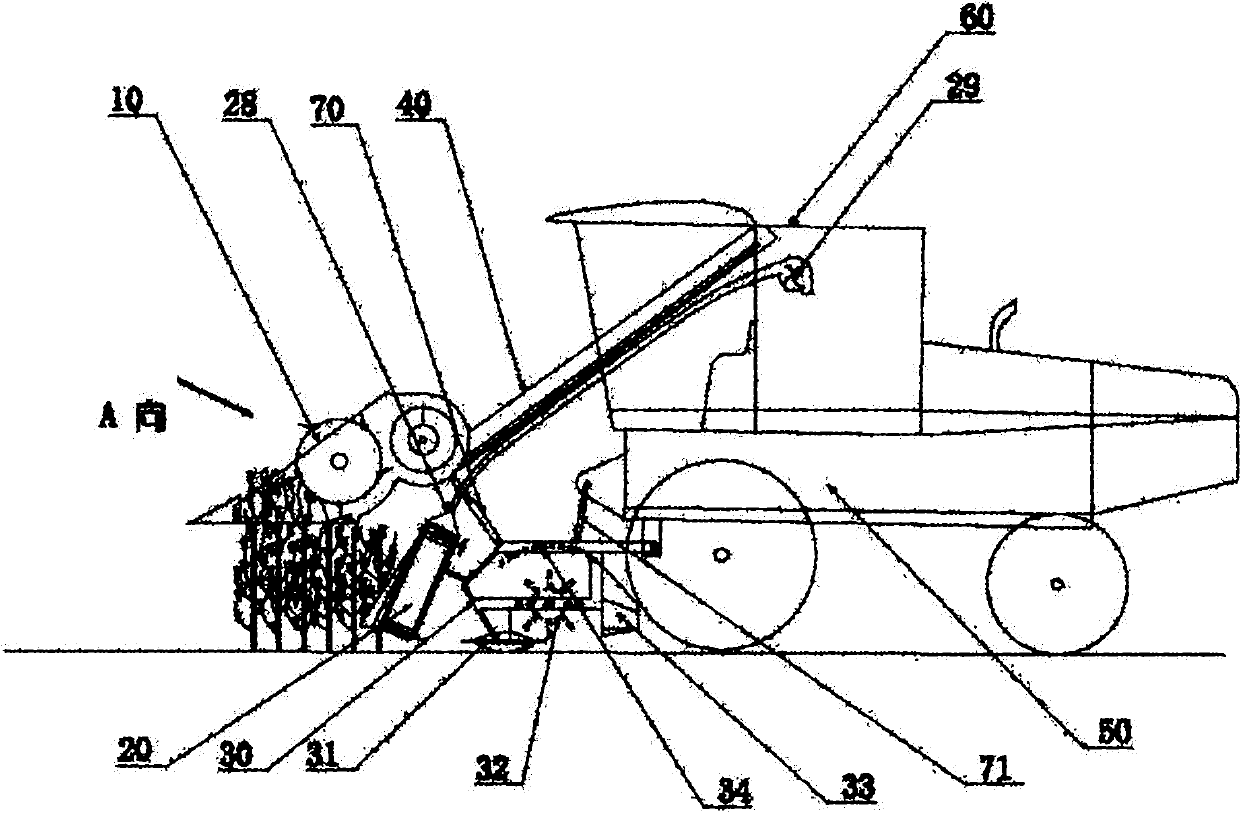

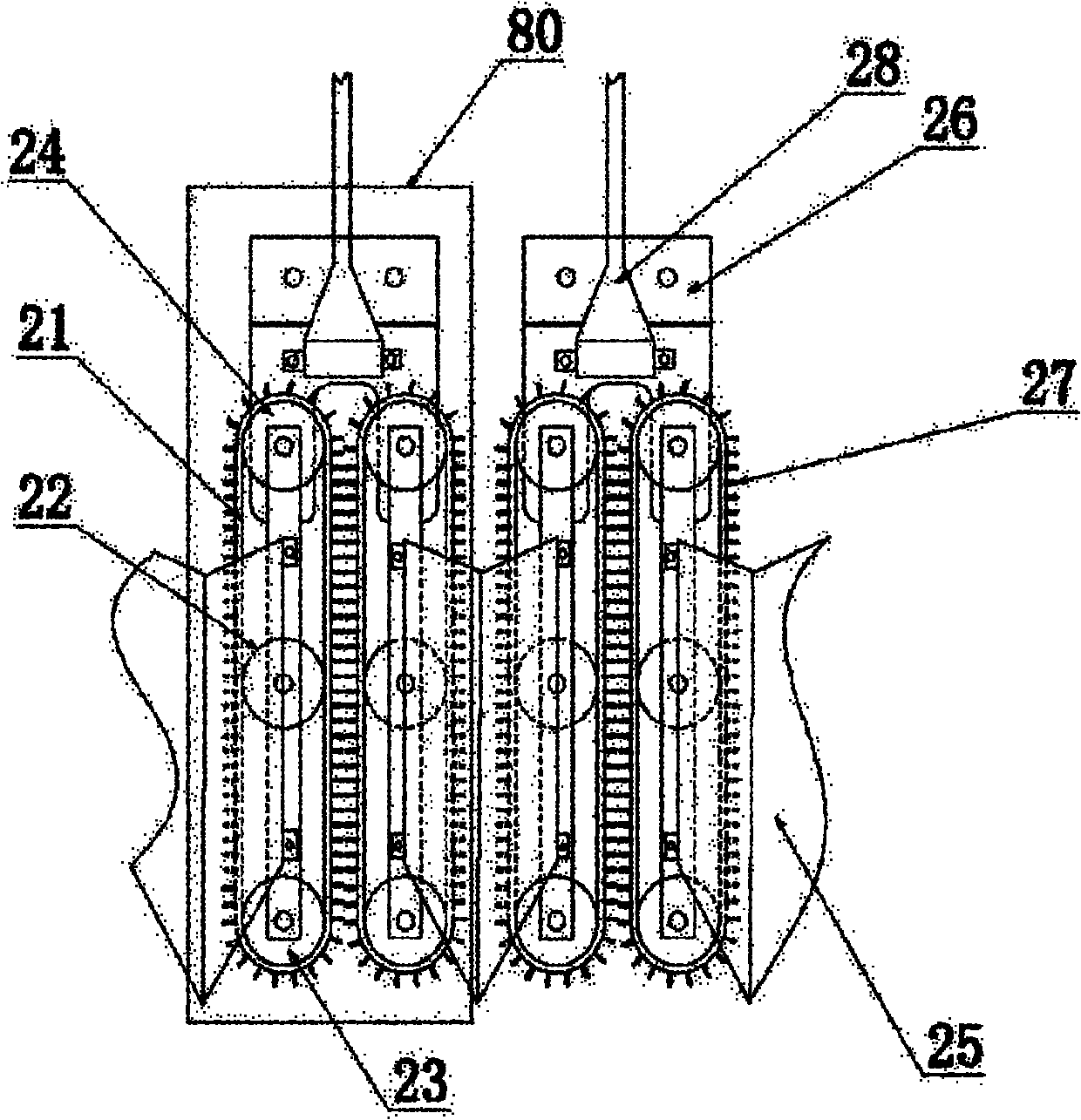

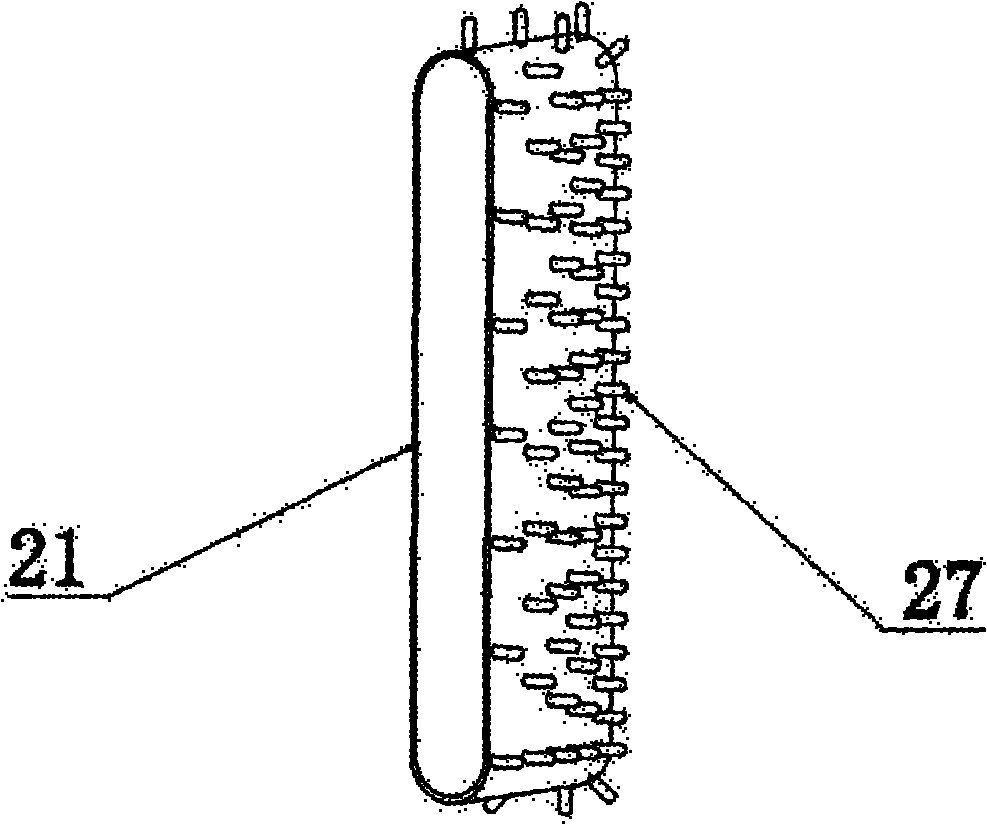

[0029] A kind of alfalfa harvester realizing the layered fractal harvesting method of alfalfa, its structure is as follows Figure 1-4 Shown:

[0030] Frame 30 rear end is connected with the lug of self-propelled chassis 50, and frame hydraulic rod 71 two ends are connected on self-propelled chassis 50 and frame 30 respectively, and frame hydraulic rod 71 is altogether two and is installed on the machine frame respectively. Both sides of the frame 30, the frame 30 can rotate around the lifting lug under the effect of the frame hydraulic rod 71, so as to realize the up and down retraction of the frame 30; Connected; The lower header 31 is fixed on the bottom of the frame 30 for harvesting the alfalfa stalks processed by the defoliator 20; Knead or beat the harvested alfalfa stems; the arc baffle plate 34 is installed above the modulator 32 with the modulator axis as the center of circle, and is used to rub the alfalfa stems with the modulator 32; the strip collector 33 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com