Indenting machine with components being rapidly changed

A creasing machine and component technology, which is applied in book binding flattening machines, book binding, printing, etc., can solve the problems of low production efficiency, long production cycle, high cost, etc., to improve production efficiency and safety performance, solve Time-consuming and labor-intensive, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

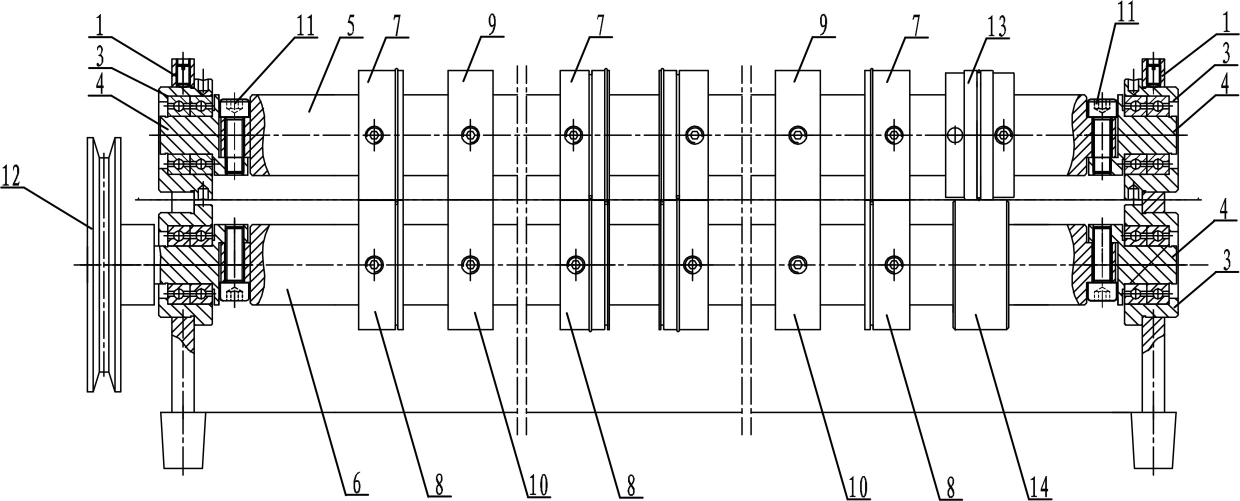

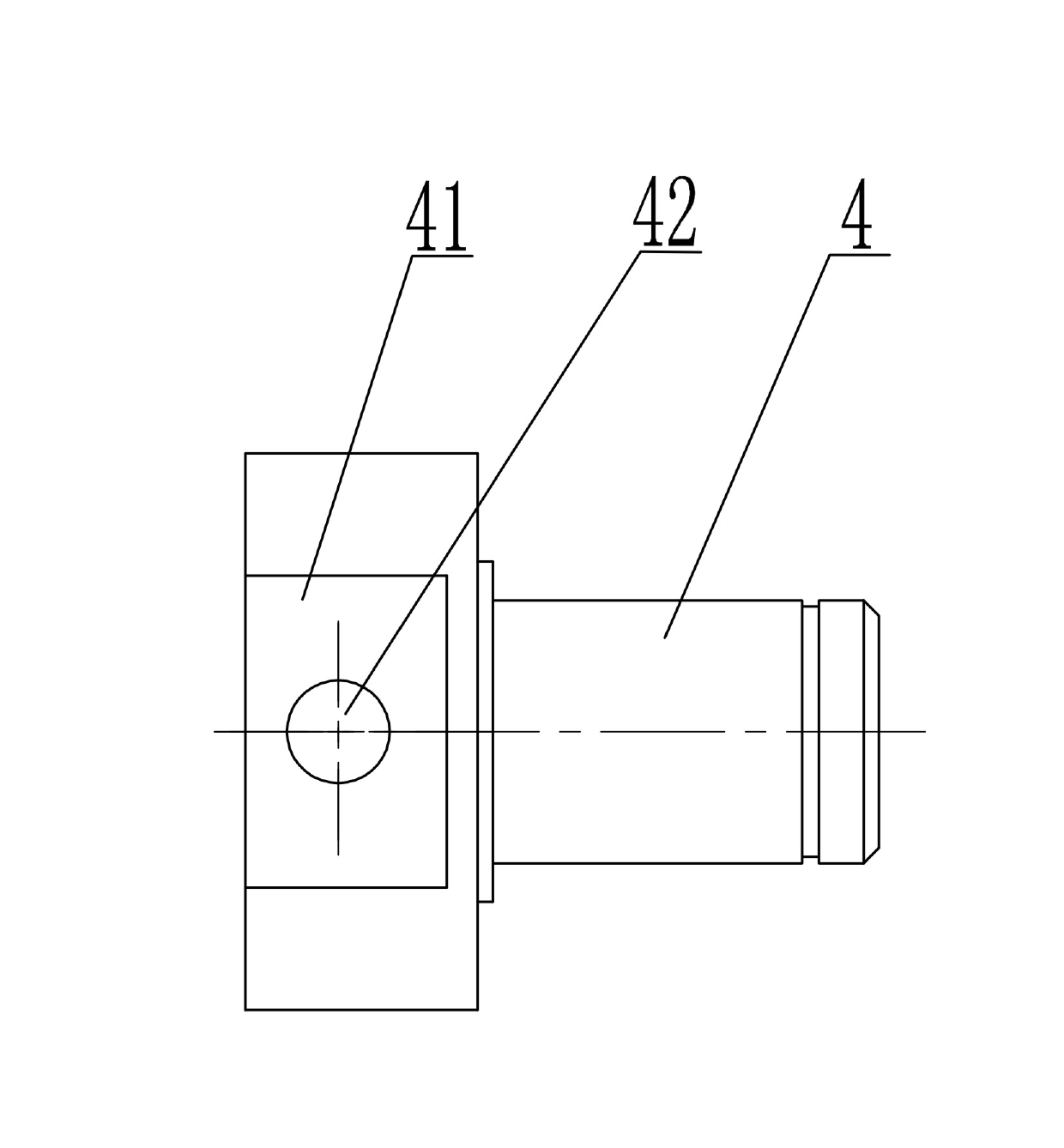

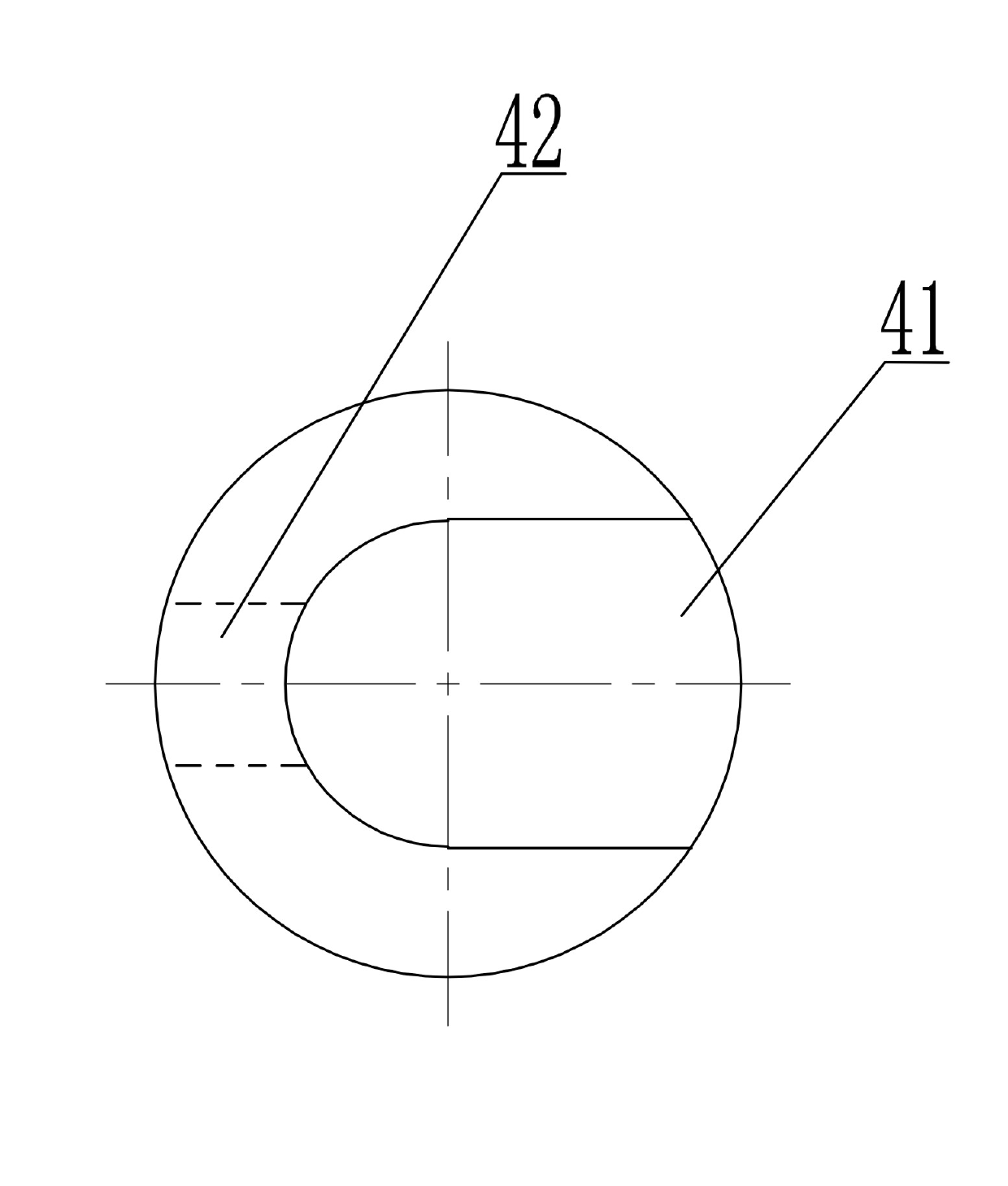

[0013] See attached figure 1 , the present invention includes: an upper drive shaft 5 and a lower drive shaft 6 arranged in parallel on the frame 1, the upper drive shaft 5 is provided with a positive creasing wheel 7, a rubber wheel 9 and a paper cutting wheel 13, and the lower drive shaft 6 is There are female creasing wheels 8, lower pressing wheels 10 and paper pressing wheels 14, several male creasing wheels 7 are arranged in one-to-one correspondence with the female indentation wheels 8, and several lower pressing wheels 10 are arranged in one-to-one correspondence with the rubber wheels 9 , the paper cutting wheel 13 and the pressing wheel 14 are arranged correspondingly, and the shaft heads at both ends of the upper transmission shaft 5 and the lower transmission shaft 6 are provided with a connecting shaft 4; The semicircular "U"-shaped groove 41 is set radially, and the bottom of the groove is provided with a threaded hole 42; the shaft heads at both ends of the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com