Bevel gear train flapping-wing aircraft

A flapping wing aircraft and gear set technology, applied in aircraft, aircraft parts, aircraft power transmission, etc., can solve the problems of low efficiency, inability to efficiently control flapping speed, flapping amplitude, etc., achieve simple mechanical structure, improve energy Efficiency and flight time, and the effect of improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

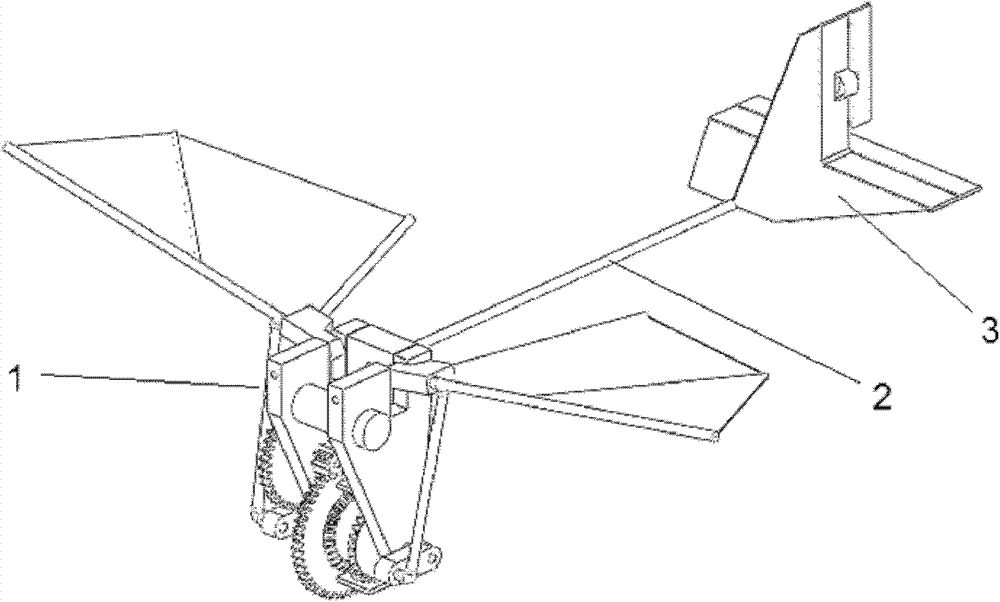

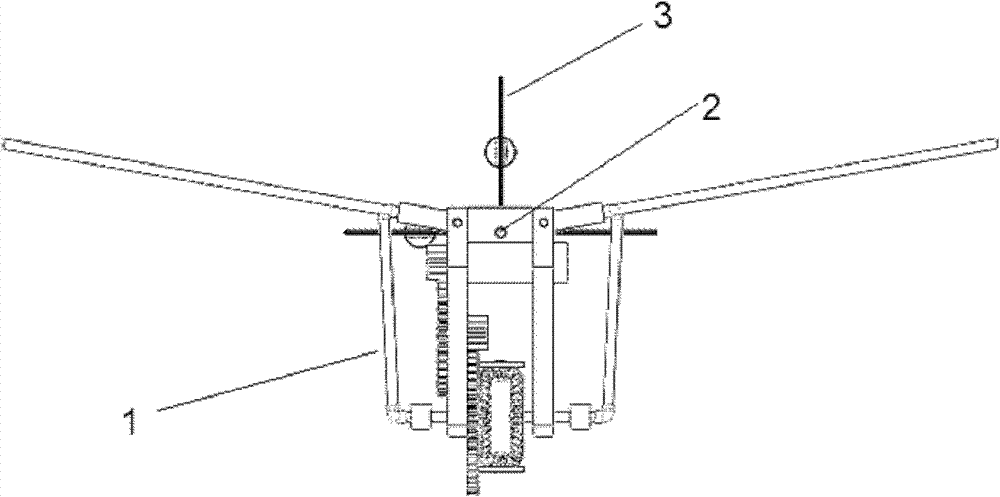

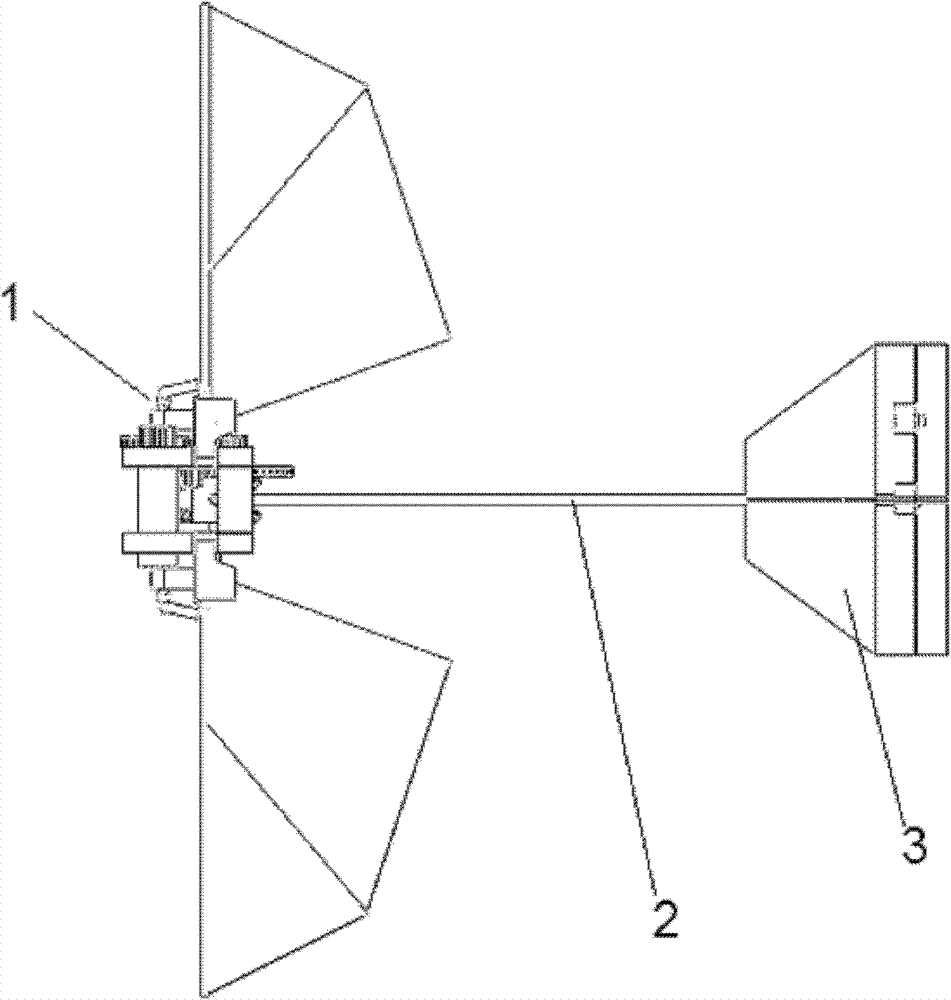

[0024] Such as figure 1 As shown, this embodiment includes: a flapping mechanism 1 , a main shaft 2 and an empennage 3 , wherein: the main shaft 2 is connected to the flapping mechanism 1 and the empennage 3 respectively.

[0025] The flapping mechanism 1 includes: two wings 4, 5, a bracket connector 6, a first chest bracket 7, a second chest bracket 8, a micro-motor 9, a motor drive gear assembly 10, a bevel gear assembly 11, a first The rocker assembly 12, the second rocker assembly 13, the first gear shaft 14 and the second gear shaft 15, wherein: two chest brackets 7, 8 are symmetrically connected to both sides of the bracket connector 6, and the bracket connector 6 is connected to the main shaft 2 connection, two chest brackets 7,8 are movably connected with two wings 4,5 respectively, two rocker assemblies 12,13 are connected with two wings 4,5 respectively, one end of the first gear shaft 14 is connected with the first rocker The rod assembly 12 is connected, the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com