Process for surface treatment of internal wall of open-end spinning frame rotor

An air spinning machine and surface treatment technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of high cost, general economy, complex process, etc., and achieve low cost, significant economic benefits, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

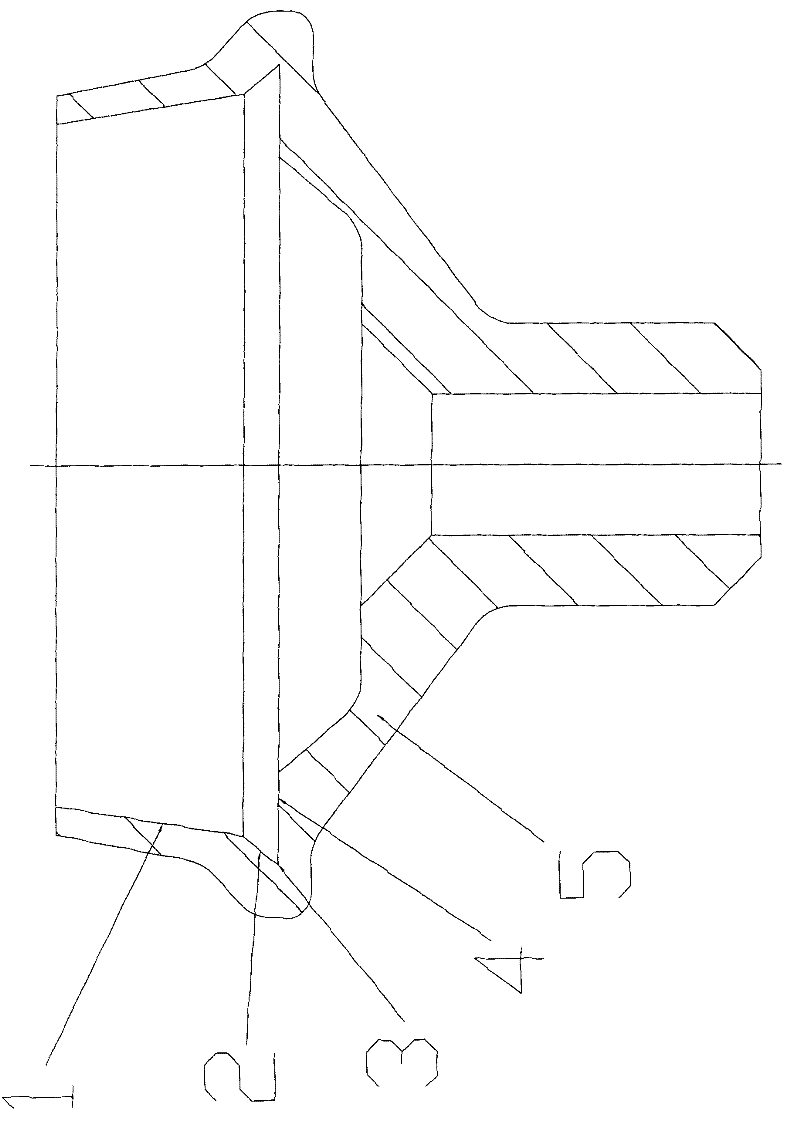

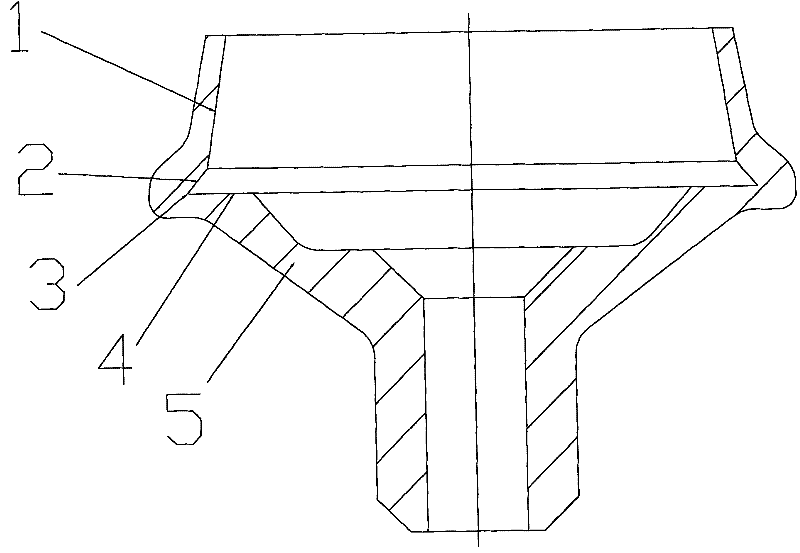

Image

Examples

Embodiment 1

[0025] The surface treatment process of the inner wall of the rotor of the air spinning machine is carried out according to the following steps:

[0026] 1) Machining, the roughness of the sliding surface and condensation groove is controlled at Ra0.7;

[0027] 2) Perform quenching treatment, heat to 800°C at medium speed, keep warm for 15 minutes, and then cool to room temperature in 20°C water;

[0028] 3) Then perform low-temperature tempering treatment, heat to 220°C at a medium speed (15-25°C / min), keep it warm for 12 minutes, and then air-cool to room temperature;

[0029] 4) Then carry out electroless nickel plating:

[0030] The process flow is: chemical degreasing→boiling water cleaning→chemical degreasing→boiling water cleaning→activation treatment→warm water cleaning→normal temperature deionized water cleaning→electroless plating→boiling water cleaning→drying→heat treatment→polishing.

[0031] In described electroless plating, the composition and content of electr...

Embodiment 2

[0037] The surface treatment process of the inner wall of the rotor of the air spinning machine is carried out in accordance with the following steps:

[0038] 1) Machining, the roughness of the sliding surface and condensation groove is controlled at Ra0.8;

[0039] 2) Perform quenching treatment, heat to 860°C at medium speed, keep warm for 20 minutes, and then cool to room temperature in 20°C water;

[0040] 3) Then perform low-temperature tempering treatment, heat at a medium speed to 230°C, keep warm for 12 minutes, and then air-cool to room temperature;

[0041] 4) Then carry out electroless nickel plating:

[0042] The process flow is: chemical degreasing→boiling water cleaning→chemical degreasing→boiling water cleaning→activation treatment→warm water cleaning→normal temperature deionized water cleaning→electroless plating→boiling water cleaning→drying→heat treatment→polishing.

[0043] In described electroless plating, the composition and content of electroless plati...

Embodiment 3

[0049] The surface treatment process of the inner wall of the rotor of the air spinning machine is carried out in accordance with the following steps:

[0050] 1) Machining, the roughness of the sliding surface and condensation groove is controlled at Ra0.9;

[0051] 2) Perform quenching treatment, heat to 900°C at medium speed, keep warm for 25 minutes, and then cool to room temperature in 20°C water;

[0052] 3) Then perform low-temperature tempering treatment, heat at a medium speed to 240°C, keep warm for 18 minutes, and then air-cool to room temperature;

[0053] 4) Then carry out electroless nickel plating:

[0054] The process flow is: chemical degreasing→boiling water cleaning→chemical degreasing→boiling water cleaning→activation treatment→warm water cleaning→room temperature deionized water cleaning→electroless plating→)boiling water cleaning→drying→heat treatment→polishing.

[0055] In described electroless plating, the composition and content of electroless platin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com