Method for machining serial number of ballastless track plate efficiently

A ballastless rail and processing method technology, applied in rails, metal processing equipment, roads, etc., can solve the problems of fast wear of engraving tools, prolonged processing time, poor aesthetics, etc., achieve uniform and beautiful font depth, and improve production efficiency. The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

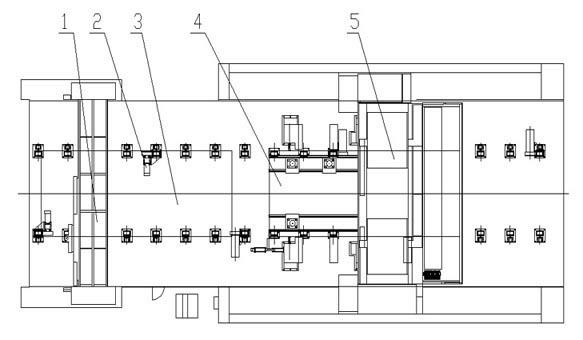

[0023] Refer to the attached figure 1 , the invention discloses a high-efficiency processing method for ballastless track plate serial number. After the track plate is ground by the grinding device and passed the inspection, it is transported to the bottom of the independent three-coordinate engraving unit 1 by a conveying trolley, and the contact in the engraving unit The measuring device actually measures the engraving position on the track plate, analyzes and calculates the measurement data by the automatic programming software, and automatically compiles the engraving processing program for the track plate serial number according to the track plate serial number transmitted by the grinding station; engraving The processing program automatically controls each servo motion axis through the CNC system of the grinding machine 5 to complete the processing of the track plate serial number; after the track plate serial number is engraved, the track plate is transported to the sub...

Embodiment 2

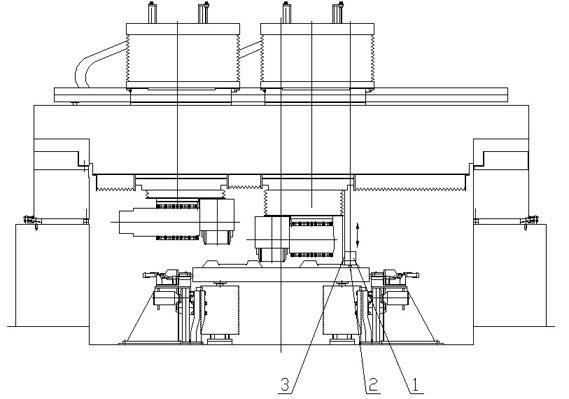

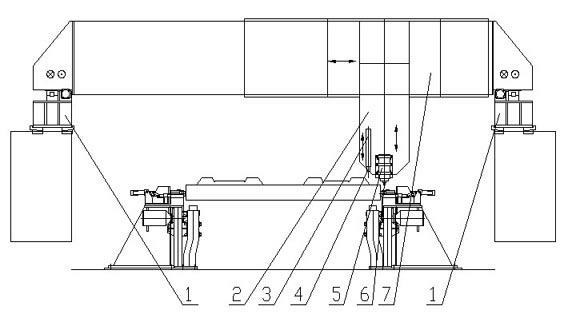

[0025] On the basis of Example 1, as a preferred embodiment of the present invention, refer to the attached image 3 The independent three-coordinate engraving unit of the present invention includes two groups of longitudinal beams 1, a crossbeam 7 supported on the two groups of longitudinal beams 1 and moving along the length direction of the track slab, supported on the crossbeam 7 and moving along the width of the track slab The vertical carriage 2 that moves in the direction, the engraving main shaft 5 that is arranged on the end of the vertical carriage 2 and moves vertically up and down, is supported on the vertical carriage 2 and is positioned at the contact measuring device of the engraving main shaft 5 side; The touch measuring device includes a touch measuring head 4 for actually measuring the engraving position on the track plate, and a vertical feed mechanism 3 for making the touch measuring head 4 move vertically up and down. Through the independent three-coordina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com