Steel plate production method based on manufacturing execution system (MES) management system

A steel plate production method and management system technology, applied in the field of billet production based on the MES management system, can solve the problems affecting the contract completion rate, large changes in production plan specifications, large changes in order specifications, etc., so as to reduce the number of unplanned products attached to contracts. , The effect of optimizing the production plan and specification and reducing the rolling loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

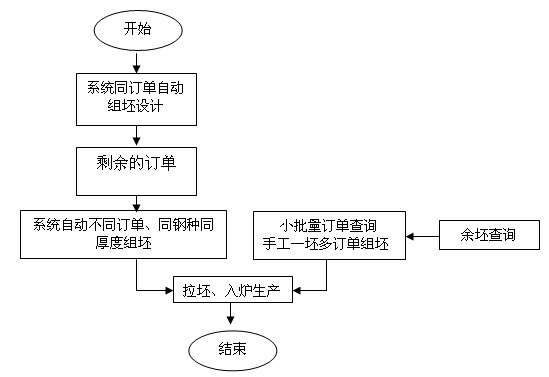

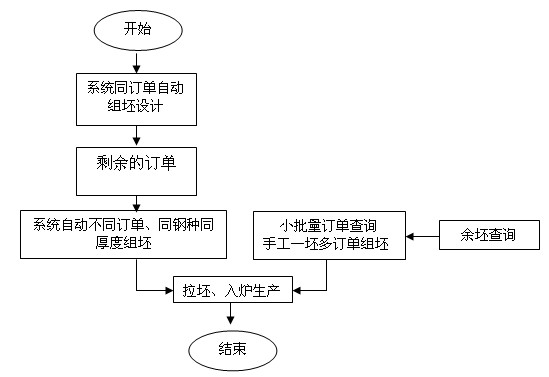

Image

Examples

Embodiment 1

[0025] Example 1 (manual design of one slab with multiple orders)

[0026] Order No.: QA111040127-19, order size 14×2000×12000mm, weight 2.638t; order number: OA111040093-16, order size 14×2000×9000mm, weight 3.956t (need 2 pieces); order number: QA111040047- 15. The order specification is 14×2000×9000mm and the weight is 1.978t. The specific process is as follows:

[0027] (1) Medium plate rolling process management - HMI slab design, query all small batch (within 10t) orders, and sort by thickness;

[0028] (2) Select the above 3 order numbers, and insert them into the blank group design from long to short;

[0029] (3) Waiting for drawing production.

Embodiment 2

[0030] Example 2 (replacement of spare blanks instead of manual one blank multi-order slab design)

[0031] Order No.: OA111030031-11, order specification is 24×1800×8000mm, weight 2.764t (1 piece); order number: OB111030021-16, order specification is 24×1600×8000mm, weight 2.457t (1 piece). The specific process is as follows:

[0032] (1) Query the remaining slabs, select the slab number 1110242336, and the specification 220×2060×1681;

[0033] (2) Medium plate rolling process management - HMI spare billet replacement screen, query all small batch orders, and sort by thickness;

[0034] (3) Select the above 2 order numbers, and put them into the blank group design from long to short;

[0035] (4) Furnace production of remaining blanks.

[0036] The invention carries out one billet multi-order billet assembly, improves the effective utilization rate of billets, reduces the unplanned products attached to the output contract, optimizes the production plan at the same time, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com