Release of stored ammonia at start-up

一种氨释放、释放出的技术,应用在储存和定量供给的系统领域

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

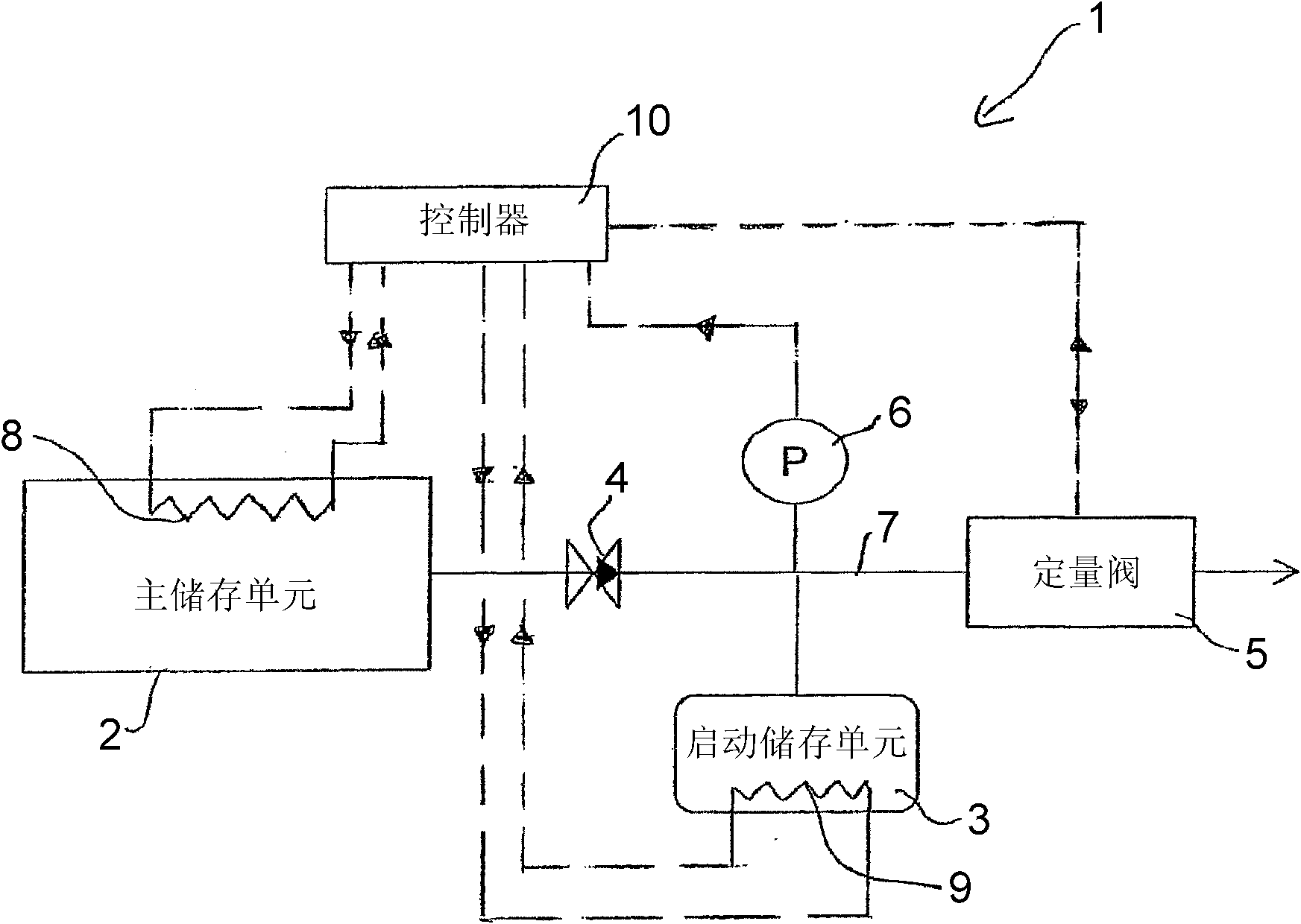

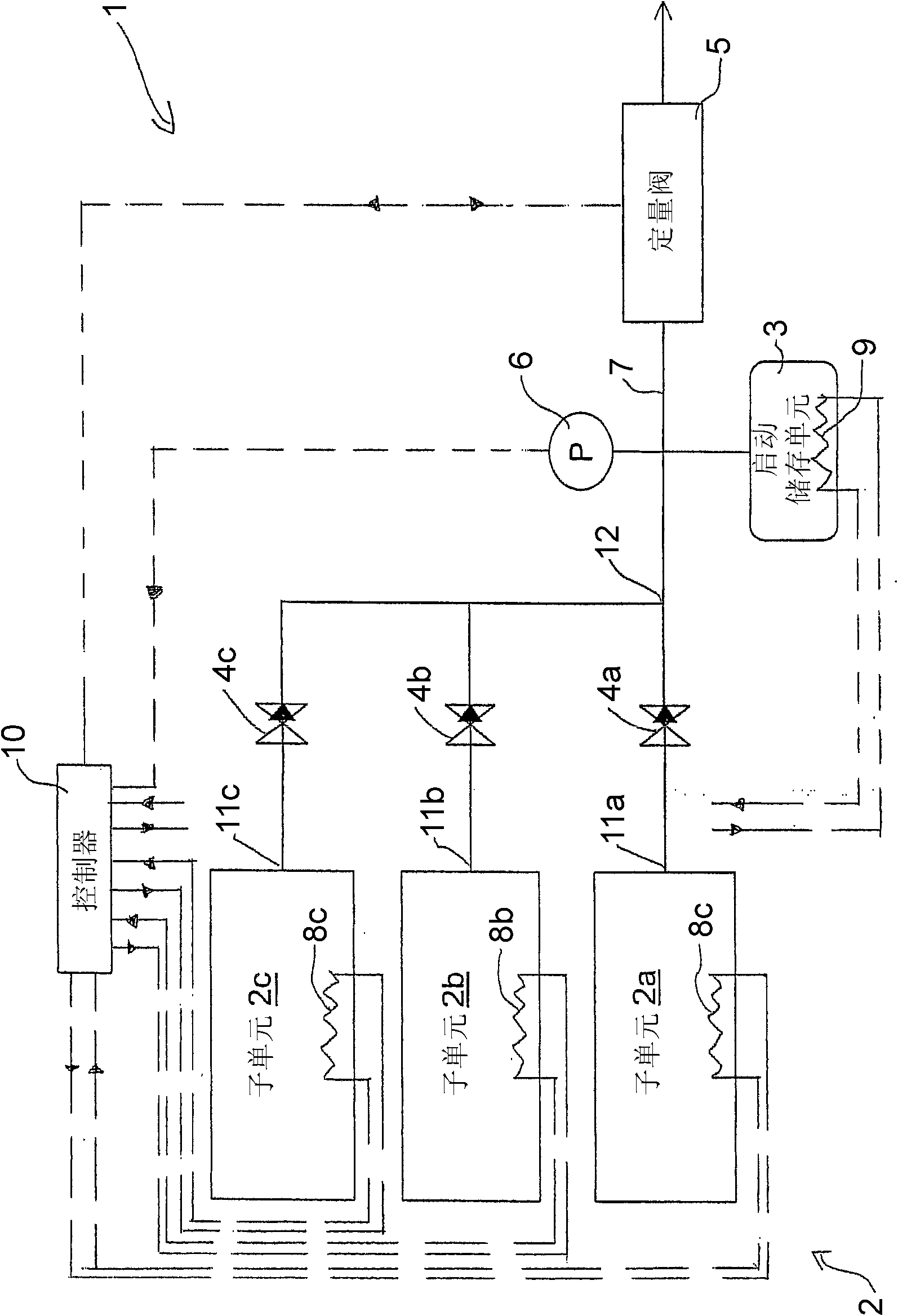

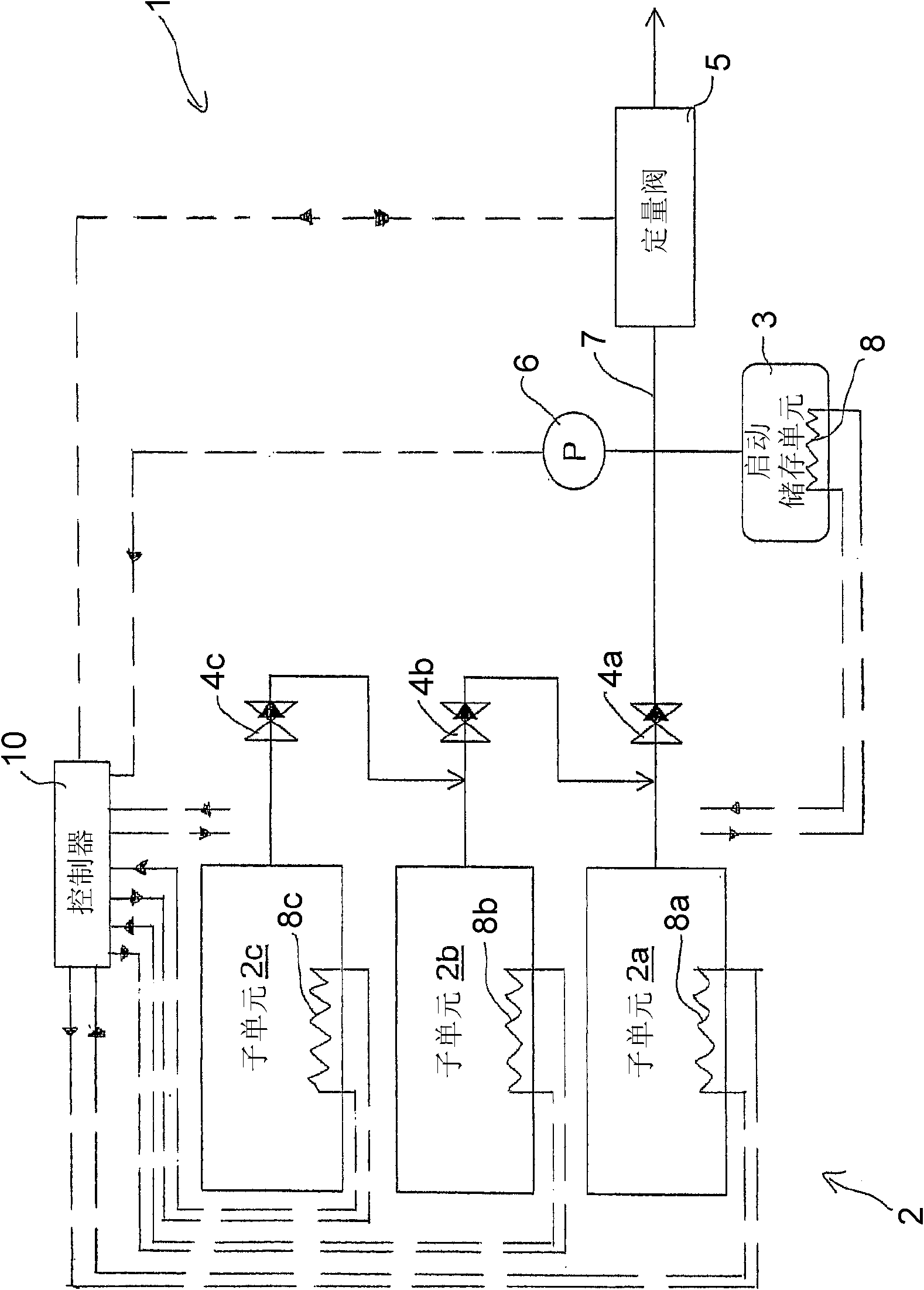

[0022] figure 1 is a schematic diagram illustrating one embodiment of an ammonia storage and dosing system with a start-up storage unit and a main storage unit. However, as we continue to describe in further detail figure 1 Before, some content will be discussed.

[0023] WO 1999 / 01205 discloses ammonia stored in a storage chamber. However, in the context of the present invention, it has been recognized that doing a quick start (in which case ammonia will be delivered after a short operating time) can be challenging if all stored material is placed in one large container . It has been recognized that making the whole system more modular is a means of reducing the challenges of having one large container (hereinafter, modules are also referred to as "containers" or "units"). The main challenge with having a single large container is that it requires relatively more energy (and thus relatively more time) to bring the temperature of the storage material up to the point where ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com