Air floating big-calibre plane optical element polishing clamp

A technology for optical components and polishing fixtures, applied in optical surface grinders, grinding/polishing equipment, manufacturing tools, etc., to achieve the effects of simple and convenient operation, reduced surface error, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, technical scheme of the present invention is further elaborated:

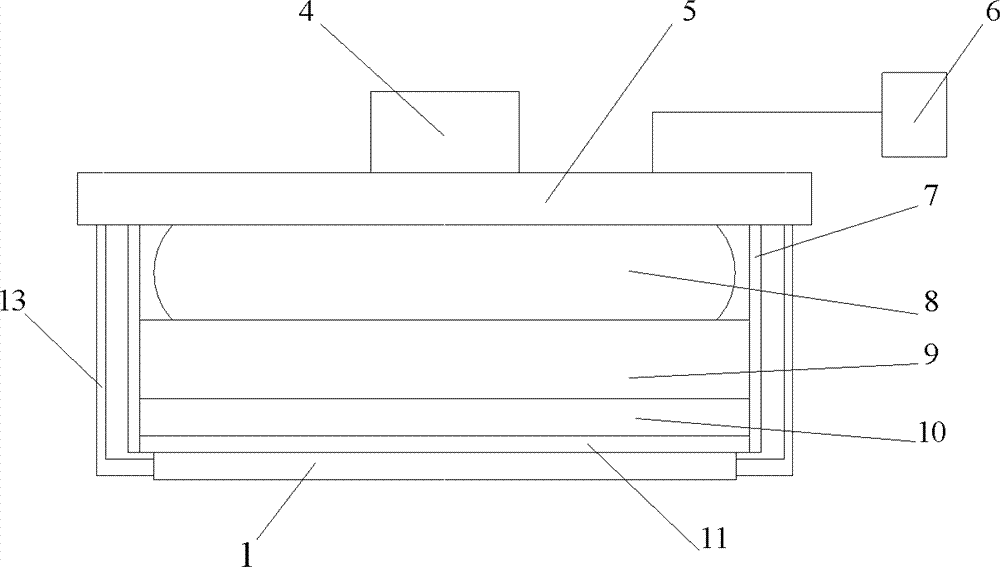

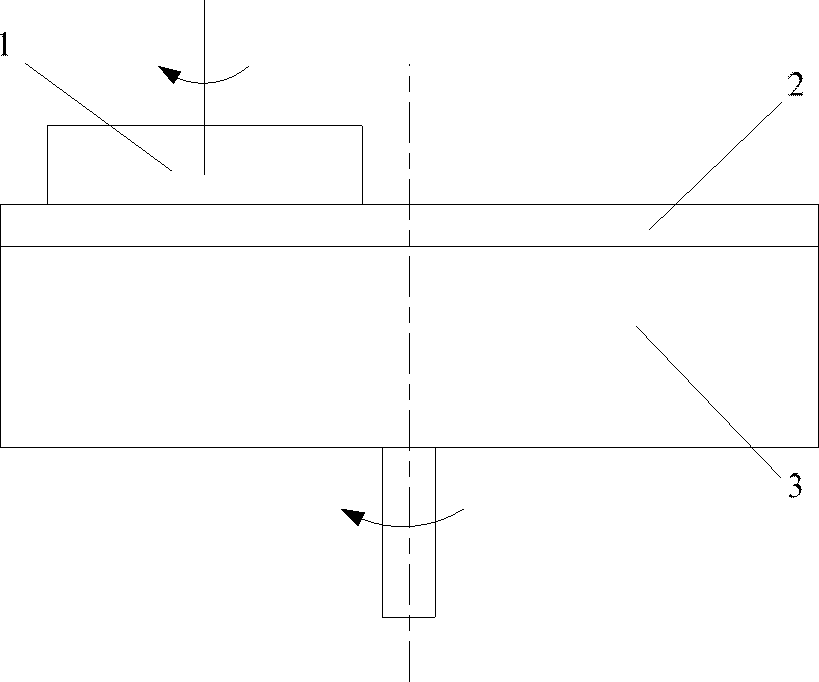

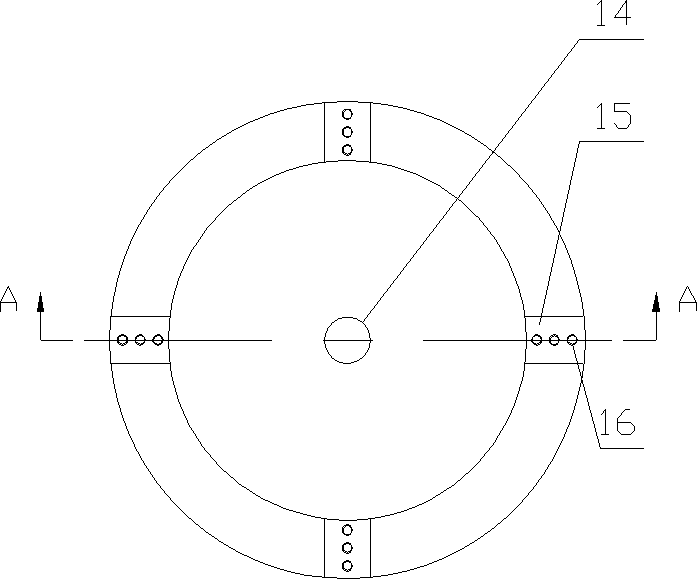

[0022] see Figure 1~6 , the embodiment of the present invention is provided with connecting shaft 4, base 5, sealing cylinder 7, air bag 8, air cushion 9, rubber film 11, 4 jaws 13 and pressure control device 6; One end of connecting shaft 4 and the upper surface of base 5 Connection, the other end of the connecting shaft 4 is externally connected to the polishing rotary shaft of the machine tool, the lower surface of the base 5 is connected to the sealing cylinder 7 through threads, the air bag 8, the air cushion 9 and the rubber film 11 are sequentially arranged in the sealing cylinder 7 from top to bottom, and the upper surface of the air bag 8 is inserted into the sealing cylinder 7. The air port is connected to the pressure control device 6 through the vent hole 14 on the base 5, the lower surface of the air bag 8 is closely attached to the upper surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com