Electroforming molding and punching integrated porous copper foil manufacturing system and method

A manufacturing system and copper foil technology, applied in electroforming, electrolytic components, electrolytic process, etc., can solve the problems of low copper foil hole efficiency and surface quality, low process flexibility, etc., to improve the dissolution localization, quality and The effect of high precision and high electrochemical dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further explained below in conjunction with the specific drawings.

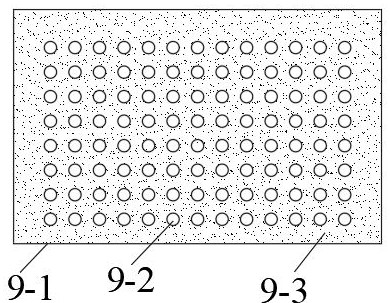

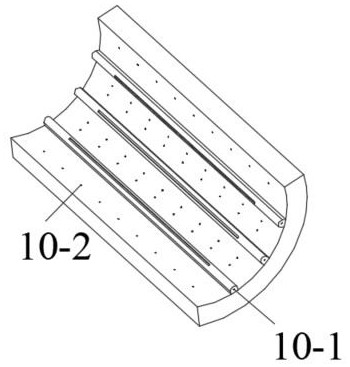

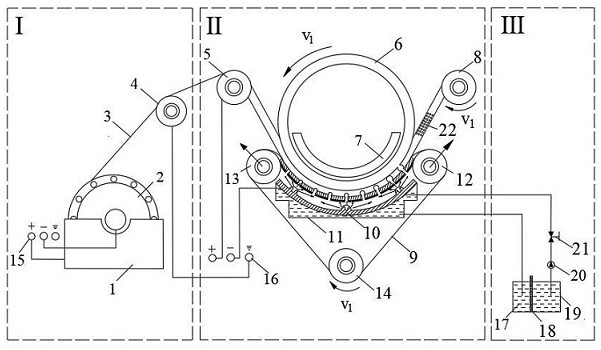

[0029] like figure 1 , figure 2 and image 3As shown, an electroforming and punching integrated porous copper foil manufacturing system includes an electroforming unit I composed of an electroforming power source 15, a copper foil 3, and a guide roller 4, an electrolyte 17, a separator 18 The electrolyte circulation unit III composed of the electrolytic cell 19, the centrifugal pump 20, and the overflow valve 21 is characterized in that: it also includes an electrolytic hole-making unit II; , arc-shaped permanent magnet 7, copper foil winding roller 8, movable mask belt 9, arc-shaped cathode 10, solution tank 11, first mask belt tension roller 12, second mask belt tension roller 13, The mask belt driving roller 14, the electrolytic power supply 16; the copper foil 3 with a width of 100 mm and a thickness of 0.006 mm is in a tensioned state and is successively guided by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com