Preparation method of rural toilet urn-shaped cement manure pit

A technology of farm toilet urn and cement, which is applied in the direction of manufacturing tools, ceramic molding machines, supply devices, etc., can solve the problems of short service life, easy to return chlorine deformation, high price, etc., and achieve high product strength, no environmental pollution, and high production efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Specific embodiments of the present invention will be described in detail below.

[0008] The present invention is implemented by the following specific steps in implementation:

[0009] 1. Prepare a pasty cement mixture by mixing 25% sulfoaluminate cement, sand 37.5% and water 37.5% at 10-30° C. to make a paste cement mixture, or 1 part by weight of sulfoaluminate cement, 1.5 parts of sand and 1.5 parts of water are mixed together at 10-30 °C to make a paste cement mixture;

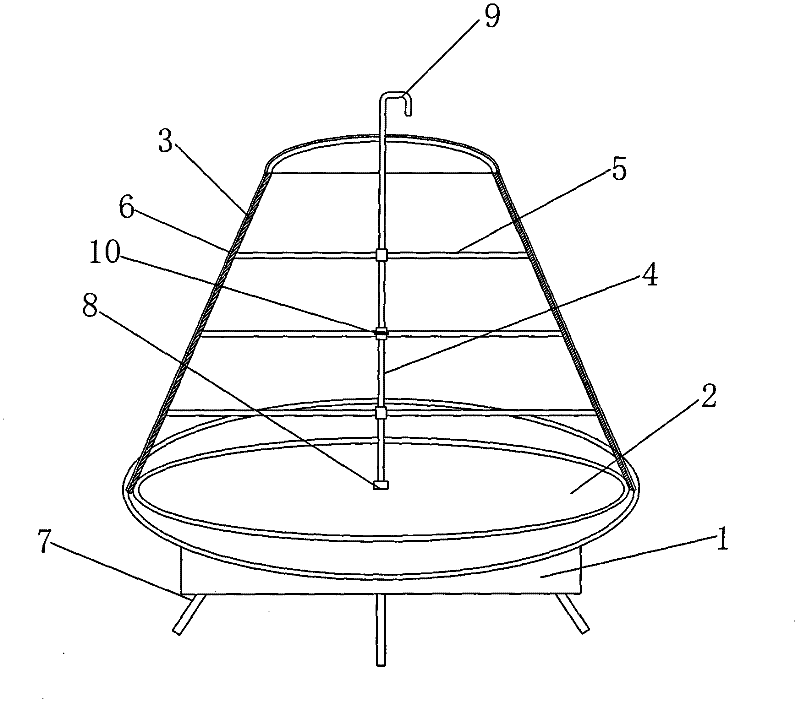

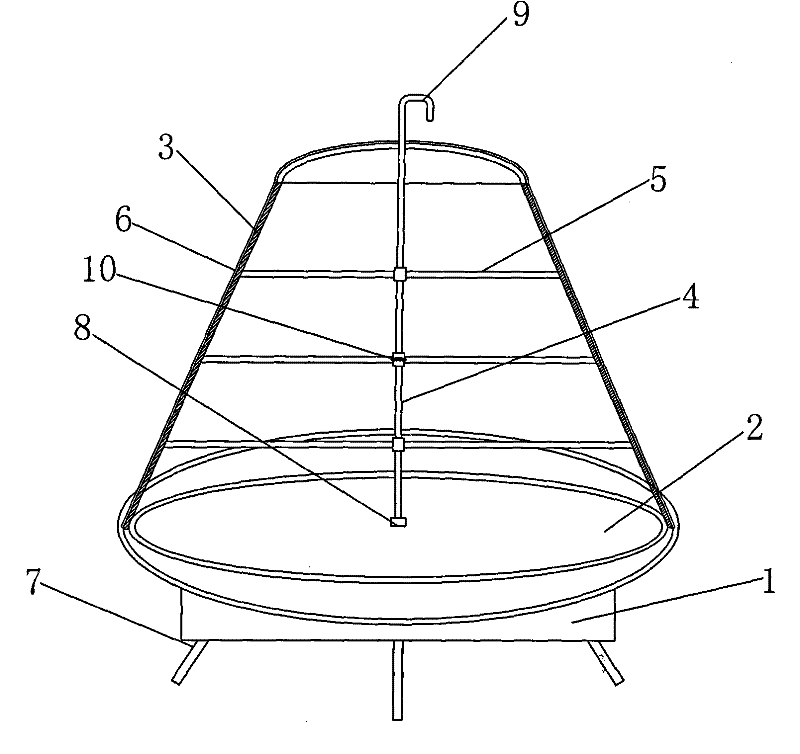

[0010] 2. Preparation of the urn body, the method is to use an arc-shaped mud wipe (a kind of smearing tool commonly used in construction, also known as a plastering board) to evenly brush the paste cement mixture on the hanging cloth of the urn mold, Apply 1.5cm thick, then hang and paste the glass fiber mesh cloth on the surface of the cement mixture, and brush the pasty cement mixture 1cm thick on the glass fiber mesh cloth, and then press it into a smooth surface to make an urn body; when th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com