Automatic balancing mechanism for platemaking roller

An automatic balancing and roller technology, applied in the direction of balancing the rotating body, etc., can solve the problems of inaccurate application of printing plates of various specifications, difficulty in universal use, complicated application and operation, etc., to achieve easy implementation, simplify the design of rollers, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

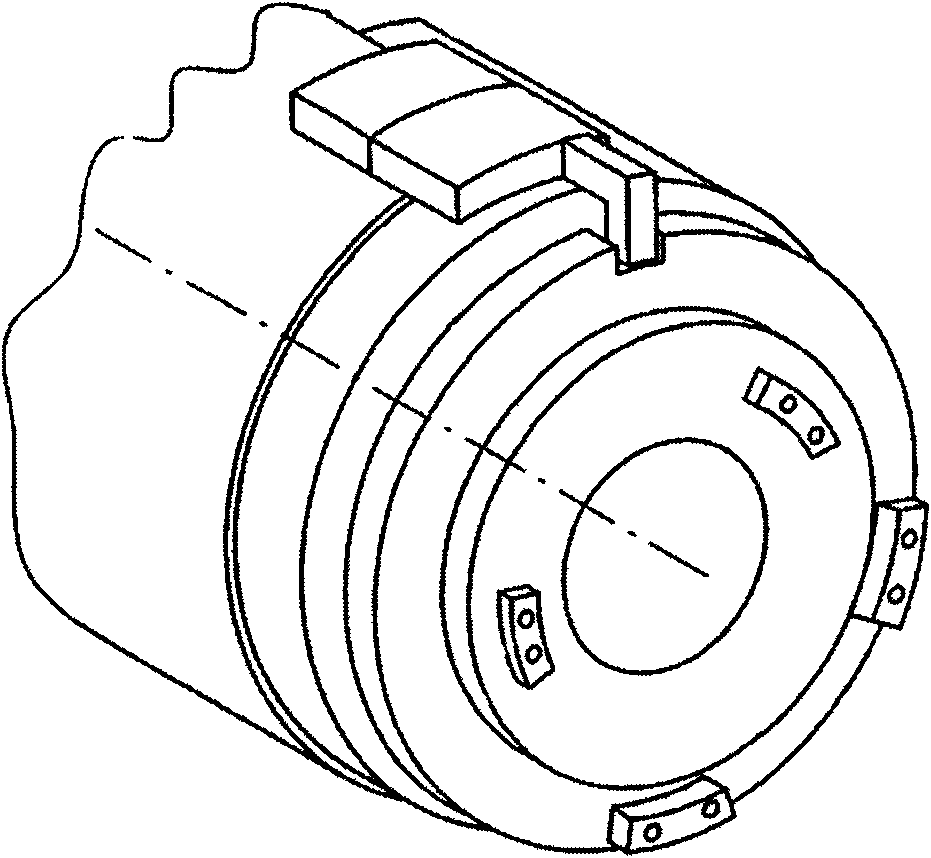

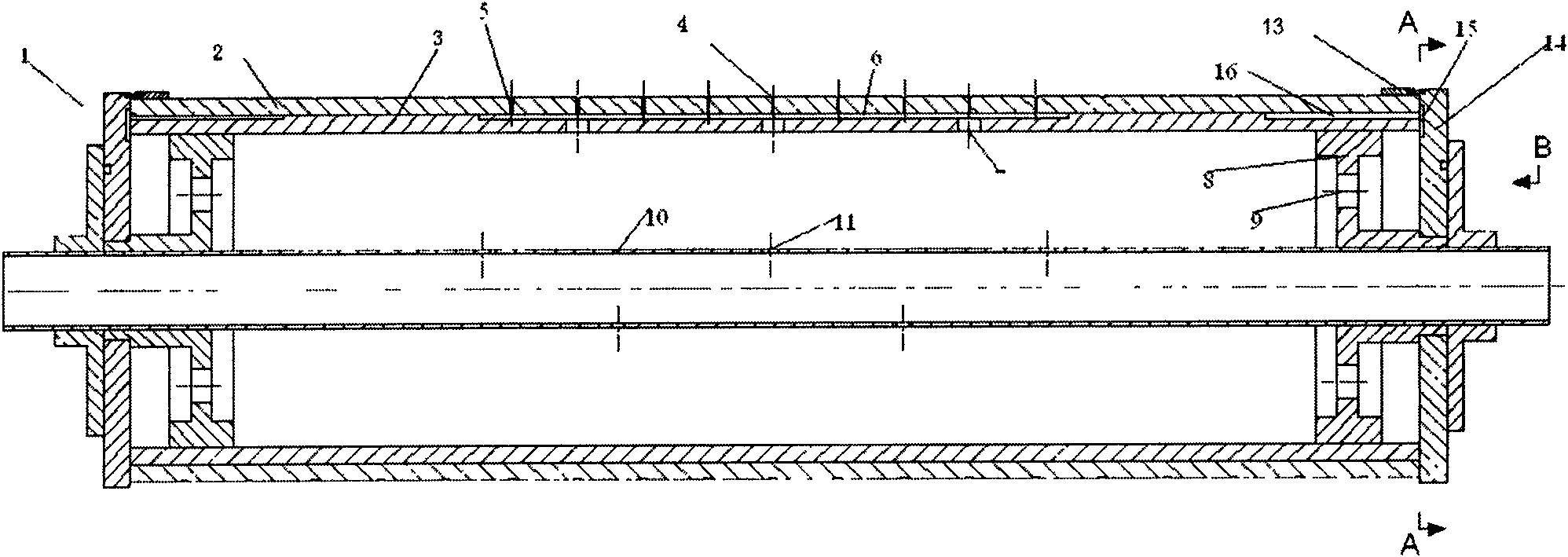

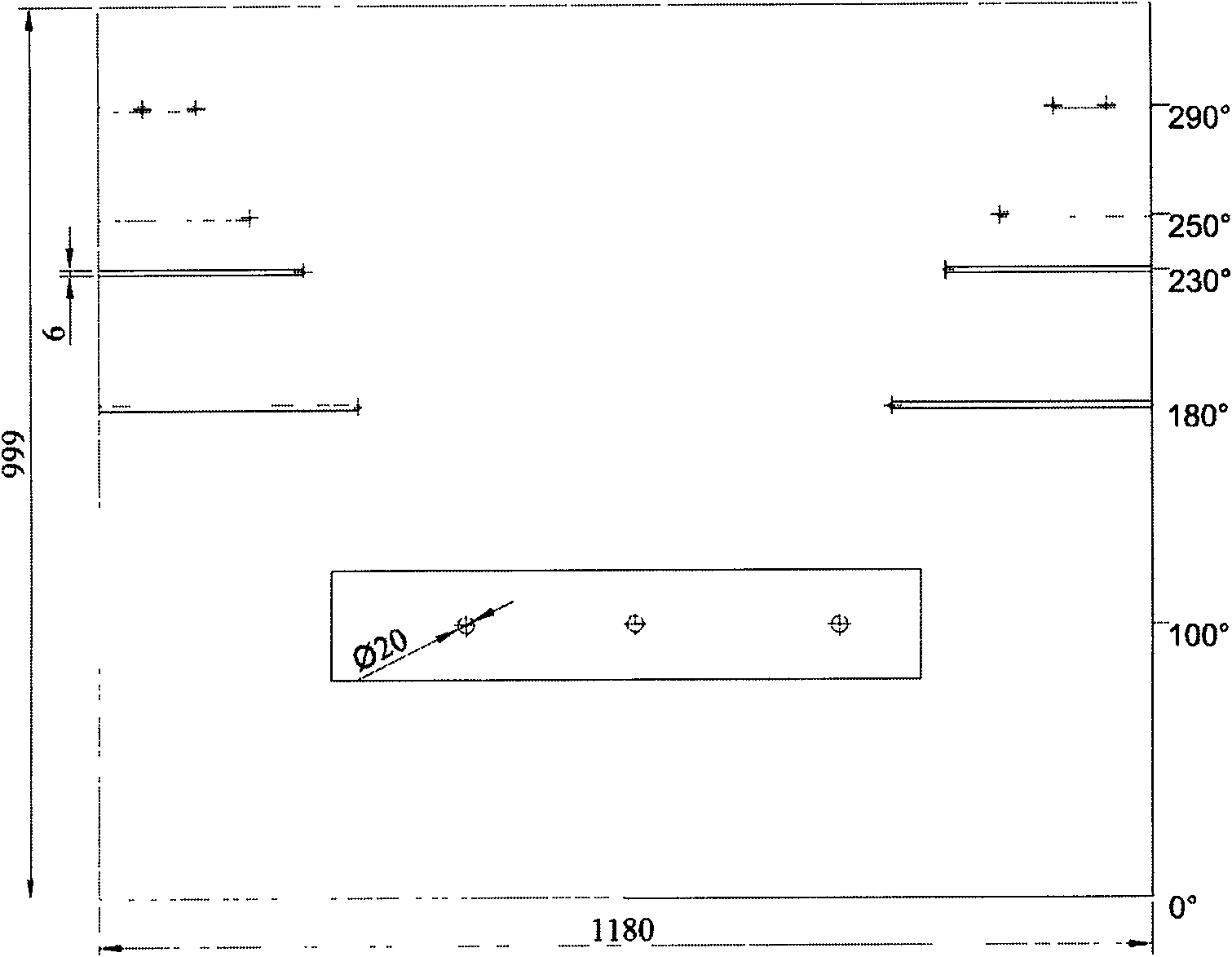

[0017] The design structure of the automatic balancing mechanism among the present invention is as figure 2 and 5 As shown: the drum 1 is composed of an outer layer drum 2 and an inner layer gas distribution drum 3 tightly closed set. There are many trapezoidal grooves 4 in the circumferential direction on the outer cylinder 2, which are distributed along the axial direction on the surface of the outer cylinder 2, so as to buckle the movable tail clamp 13. The head plate holder 12 is fixed on the outer layer cylinder 2 . Inside each groove 4 there is an air extraction hole 5 along the direction of the groove. The inner air distribution drum 3 and the inner wall of the outer layer drum 2 form an air chamber 6 , and the air chambers 6 are centered and symmetrically distributed with respect to the inner air distribution drum 3 . A first air passage 7 is opened symmetrically below the inner air chamber 6 of the inner air distribution roller 3 . Air passage holes 9 are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com