Dividing wall type regenerative cooling air oxygen alcohol torch type igniter

A regenerative cooling and igniter technology, applied in combustion ignition, incandescent ignition, jet propulsion devices, etc., can solve problems such as inconvenient use and maintenance, low ignition energy, and poor reliability of igniters, so as to reduce processing difficulty and meet ignition requirements , Guarantee the effect of cooling reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

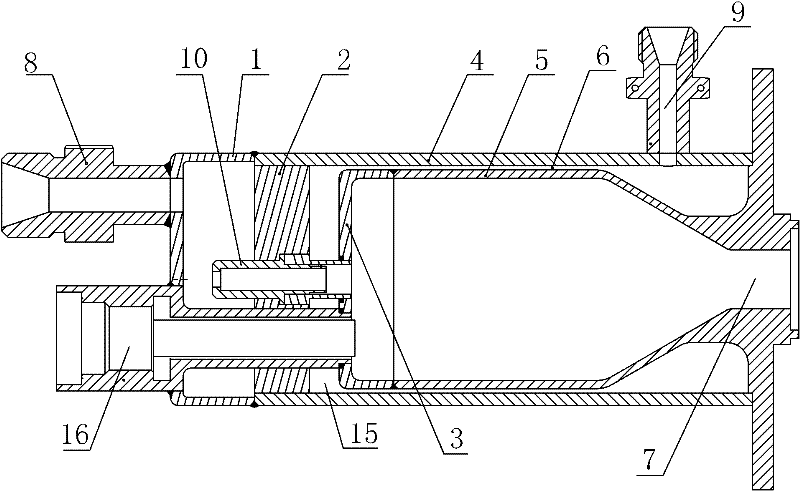

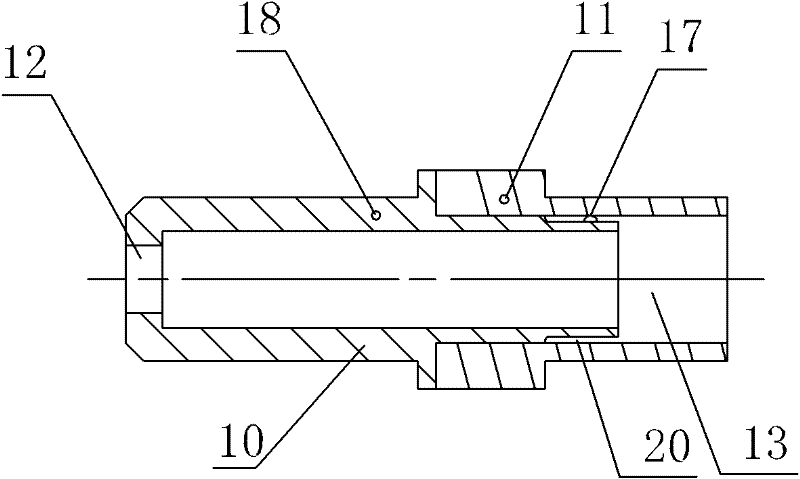

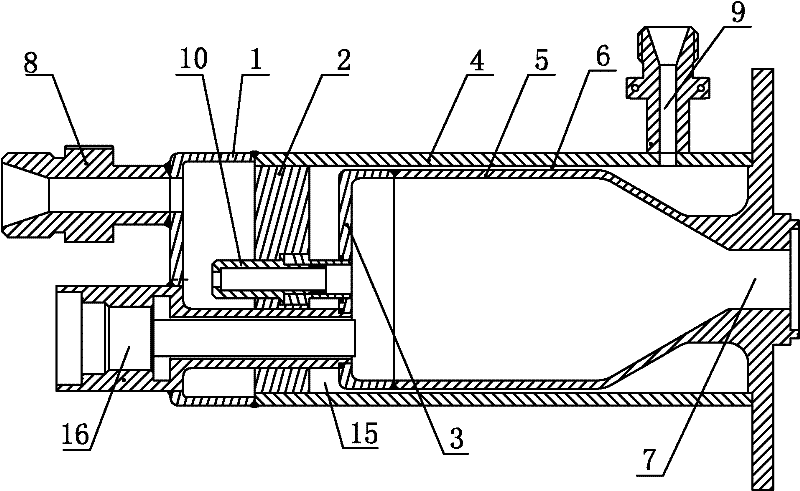

[0018] The partition wall regenerative cooling gas oxygen alcohol torch igniter of the present invention comprises an oxidizer assembly, a fuel assembly, a midsole 2, a spark plug 16, a nozzle assembly 10 and a combustion chamber 5; The oxidant inlet nozzle 8, the oxidant shell 1 and the midsole 2 constitute the oxidant chamber; the fuel assembly includes a cooling jacket 4 wrapped outside the combustion chamber 5, a fuel inlet nozzle 9 arranged on the cooling jacket, and the midsole 2 The other end surface and the inner bottom of the fuel injection liquid collection chamber 15 are formed. The oxidant shell 1 and the midsole 2 are welded to form an oxidant chamber; the oxidant inlet nozzle and the fuel inlet nozzle are respectively welded to the oxidizer shell and the cooling jacket to form the propellant inlet. To ensure reliable cooling of the igniter, a cooling jacket is designed. The gap formed between the cooling jacket and the combustion chamber constitutes the regenera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com