Method and device for controlling rotating speed of fan of electronic equipment

A technology of fan speed and electronic equipment, applied in pump control, mechanical equipment, machine/engine, etc., can solve the problems of high aerodynamic noise, speed oscillation, and large air volume margin of the fan, so as to reduce the number of adjustments, prolong the service life, The effect of ensuring the reliability of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0068] A control method and control device for the fan speed of electronic equipment, aiming at solving the problem of uniform heat dissipation and noise reduction requirements of electronic equipment.

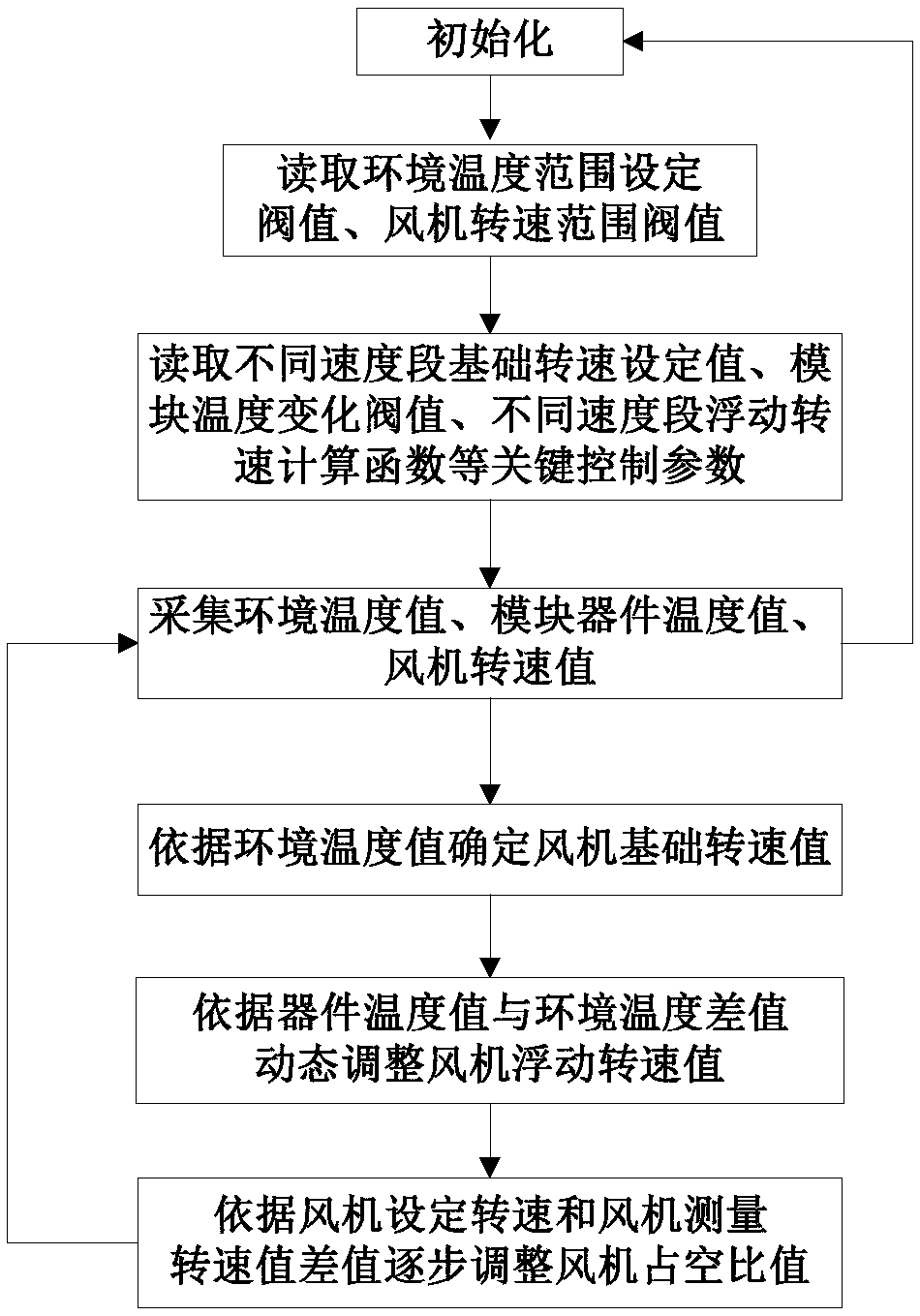

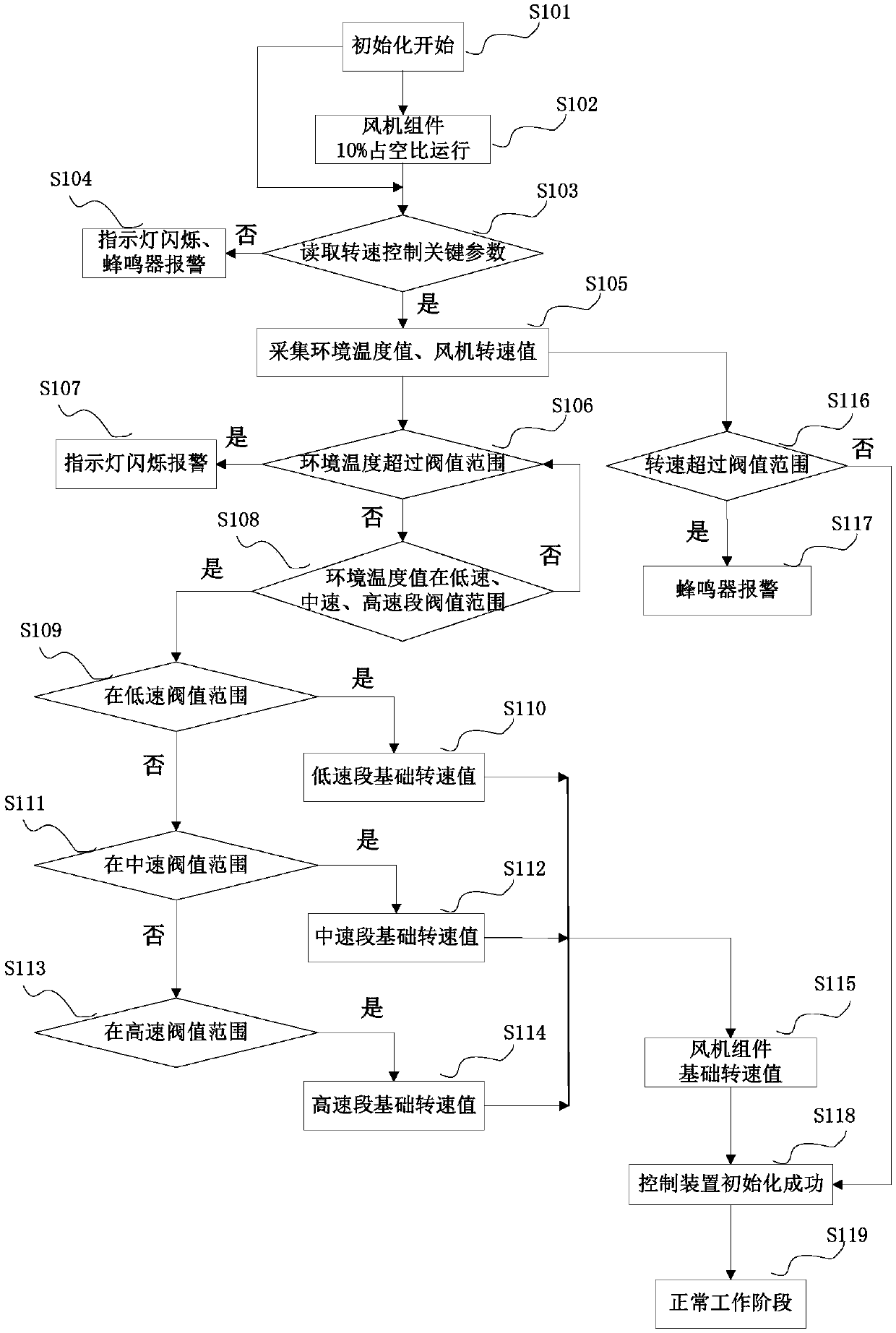

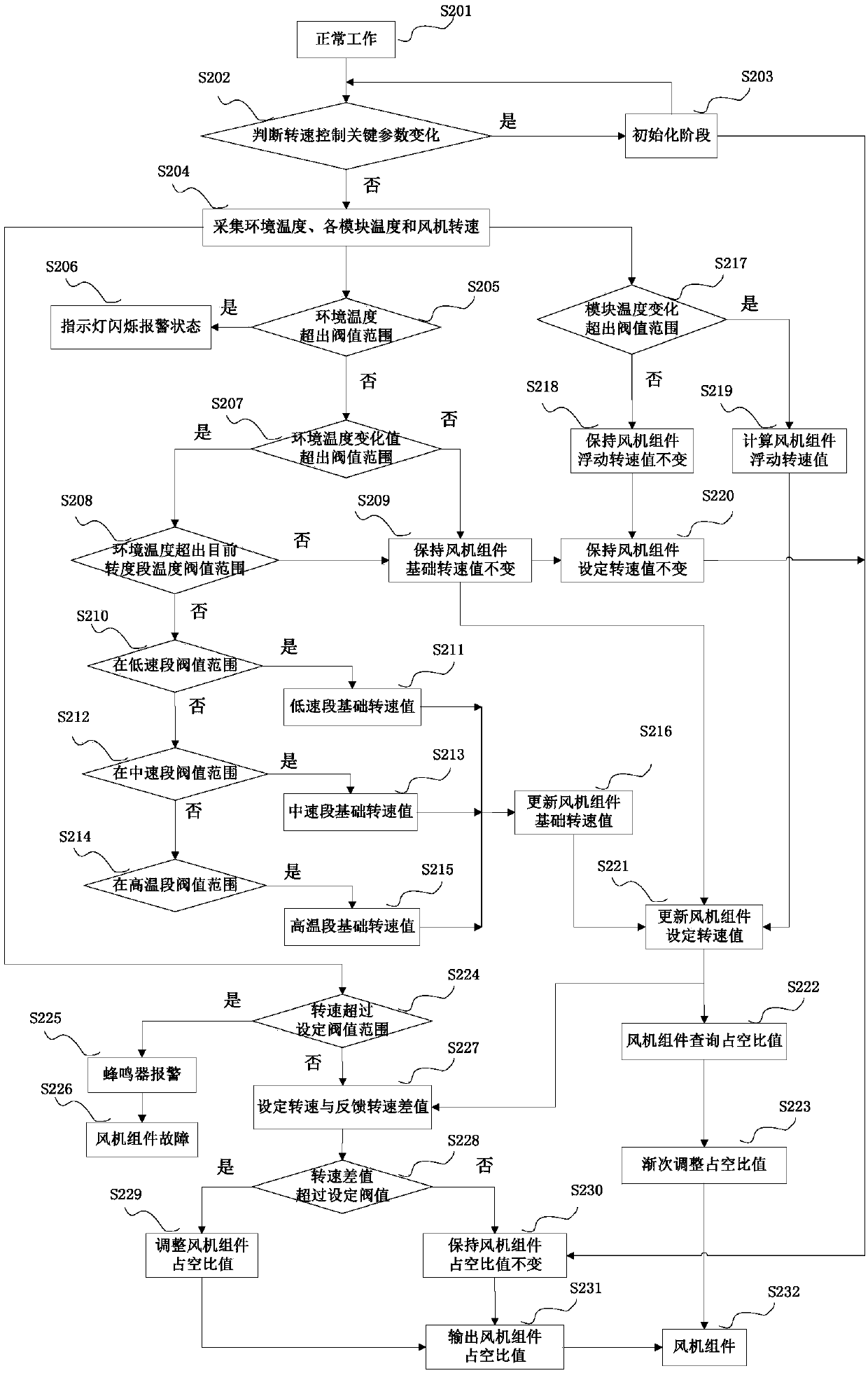

[0069] The invention adopts the strategy of "basic speed + floating speed" to adjust the speed of the fan, selects the basic speed of the fan in the low-speed section, medium-speed section, and high-speed section according to the range of ambient temperature values, and dynamically adjusts the floating speed value of the fan in real time according to the change value of the maximum device temperature value of each module Combined method to determine the fan speed required by electronic equipment, and realize the organic unity of heat dissipation and noise reduction requirements of electronic equipment; set the ambient temperature change threshold, the device temperature change threshold, and the maximum adjustment amplitude of the duty cycle to reduce the fan speed Adjust the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com