Line scanning differential confocal measuring device based on light path of pillar lens

A differential confocal and measurement device technology, applied in the direction of measurement devices, optical devices, instruments, etc., can solve the problems of low measurement efficiency, achieve the effects of reducing measurement errors, uniform beam intensity distribution, and realizing three-dimensional measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

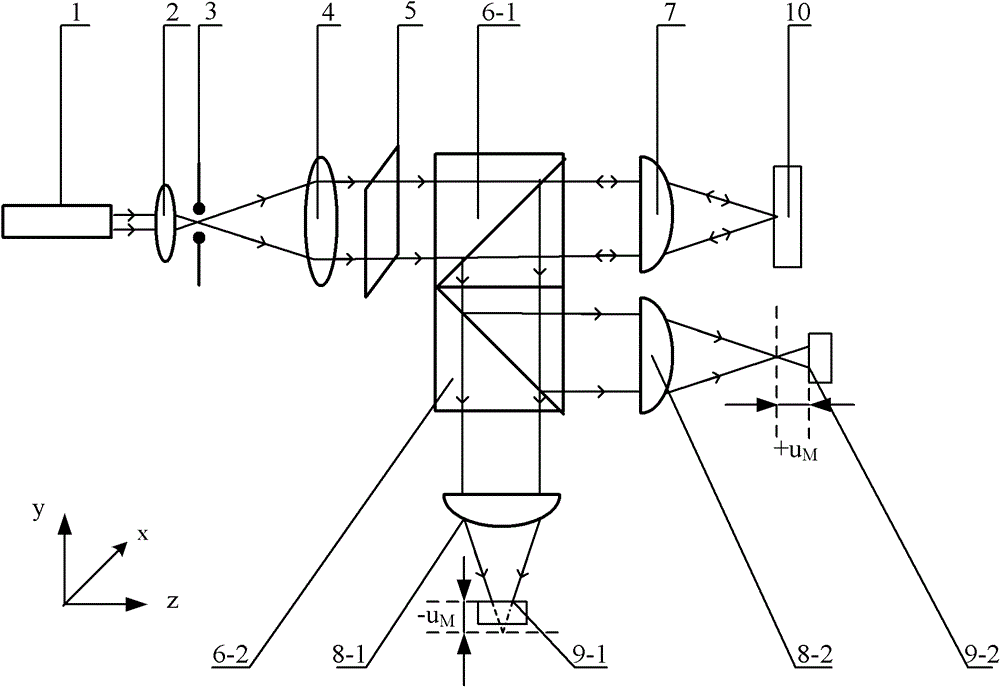

[0026] Specific implementation mode one: the following combination Figure 1 to Figure 3 To describe this embodiment,

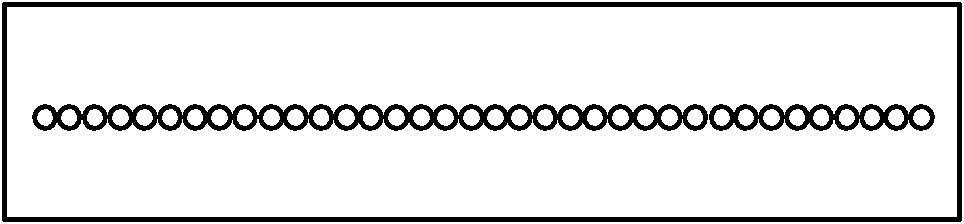

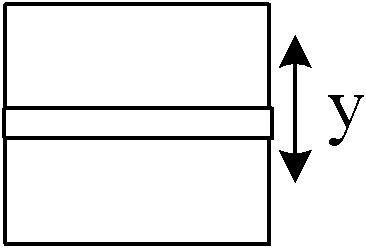

[0027] This embodiment includes a laser 1, a focusing lens 2, a pinhole 3, and a collimating beam expander lens 4 arranged in sequence on the coaxial optical path, and it also includes a rectangular diaphragm 5, a first beam splitter 6-1, and a second beam splitter 6-2. Detection focusing cylindrical lens 7, first collecting cylindrical lens 8-1, second collecting cylindrical lens 8-2, first linear array point detector 9-1 and second linear array point detector 9-2,

[0028] The laser beam generated by the laser 1 converges on the pinhole 3 through the focusing lens 2, and the point light source filtered by the pinhole 3 is expanded by the collimating beam expander lens 4, and then enters the first beam splitter 6- 1,

[0029] The transmitted light beam transmitted by the first beam splitter 6-1 is incident on the detection focusing cylindrical lens 7, and ...

specific Embodiment approach 2

[0036] Specific implementation mode two: the following combination figure 1 To describe this embodiment,

[0037] This embodiment is a further description of Embodiment 1, and the pinhole 3 is arranged at the focal point of the image side of the focusing lens 2 . Others are the same as the first embodiment.

specific Embodiment approach 3

[0038] Specific implementation mode three: the following combination figure 1 To describe this embodiment,

[0039] This embodiment is a further description of Embodiment 1 or 2. The focus on the image side of the focusing lens 2 coincides with the focus on the object side of the collimator and beam expander lens 4 . Others are the same as the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com