High-precision compensation method for horizontal angle of electro-optic theodolite

A technology of photoelectric theodolite and compensation method, applied in theodolites, instruments, measuring devices, etc., can solve problems such as inability to accurately reflect the influence of vertical axis inclination, difficult real-time measurement, and ignoring different error coupling problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Now in conjunction with accompanying drawing, the present invention is described in further detail:

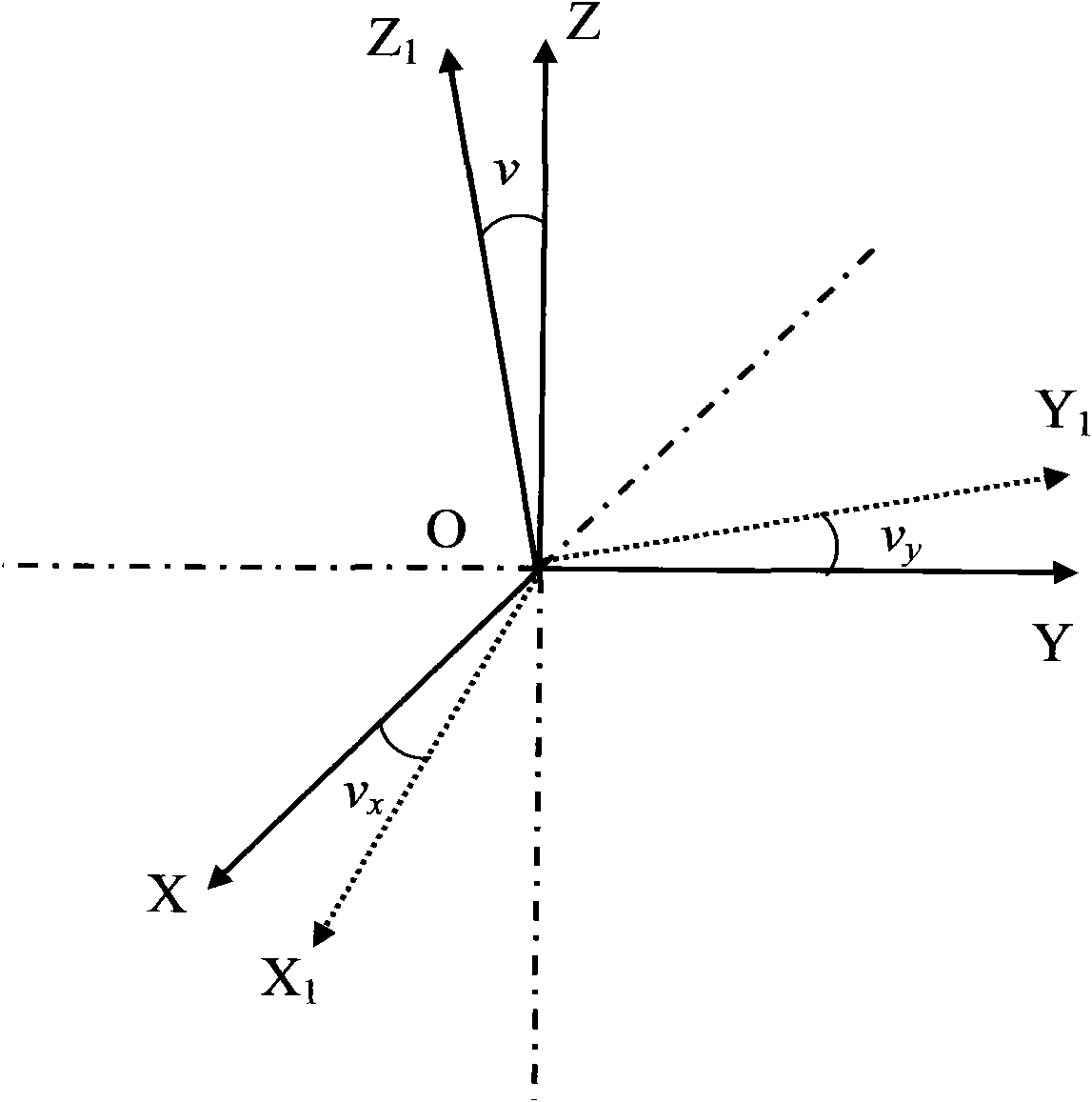

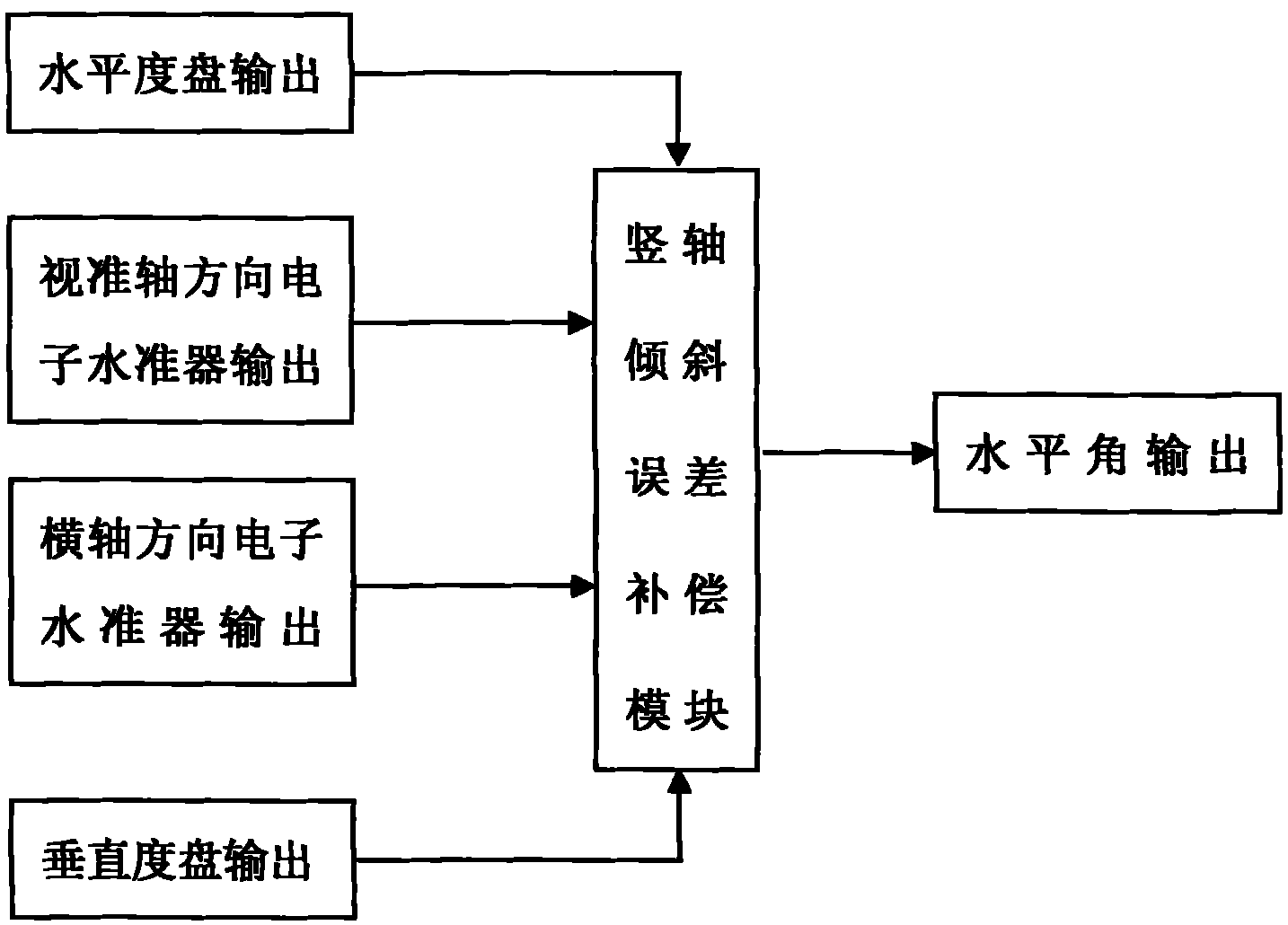

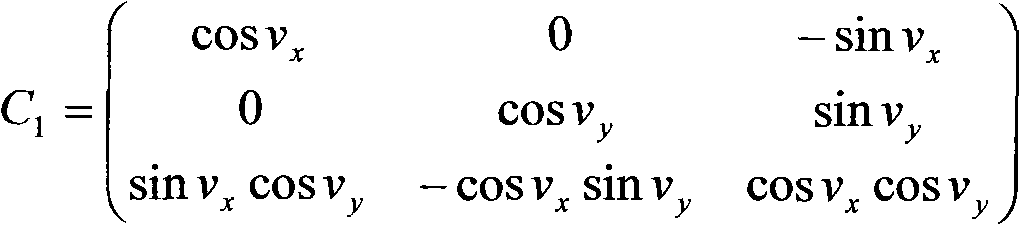

[0028] see figure 1 : The figure shows the three axes of the electronic total station and the electronic theodolite, wherein: X-axis-theodolite horizontal axis; Y-axis-theodolite collimation axis; Z-axis-theodolite vertical axis; v-vertical axis inclination angle; x 1 Axis - the horizontal axis points when there is a vertical axis tilt; Y 1 Axis - where the collimation axis points in the presence of vertical axis tilt; Z 1 Axis - where the vertical axis points when there is a vertical axis tilt; v x - the angle by which the horizontal axis deviates from the horizontal when the vertical axis is tilted; v y - The angle by which the collimation axis deviates from the horizontal when the vertical axis is tilted. In the inventive method, two electronic levels are arranged respectively in parallel to the theodolite transverse axis and the collimation axis direction, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com