Method and system for detecting purifying capacity of electrostatic oil smoke purifier

A technology of oil fume purifier and purification ability, which is applied in the direction of electric power measurement, instruments, and measurement devices by using electromagnetic effect devices, which can solve the problems of purifiers losing purification ability, troublesome operation, and long time consumption, and achieve good market prospects. Easy maintenance and quick response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

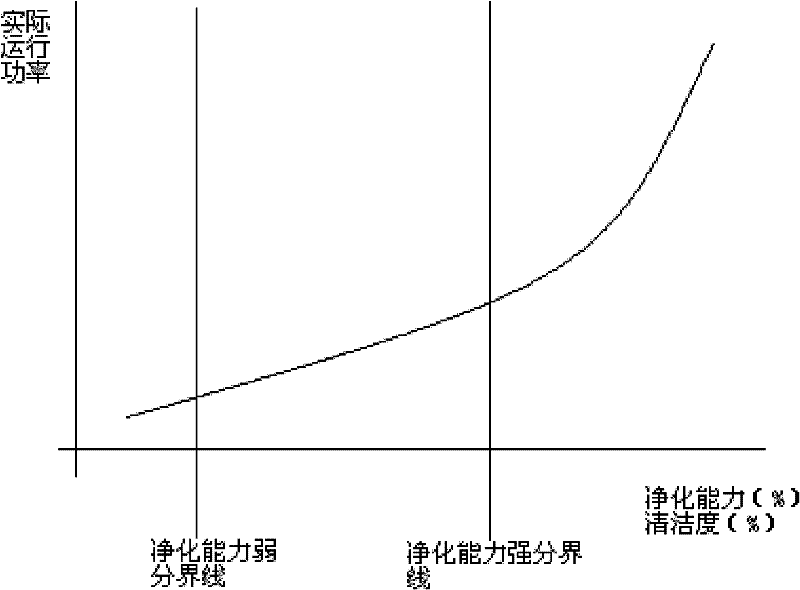

[0029] As the purifier (hereinafter referred to as the purifier) prolongs the use process, as more and more oil particles are adsorbed on the plate, the electric field on the plate will gradually weaken, and the purification ability of the purifier will gradually decrease, and even failure will occur. The case of purification. When the purification ability of the purifier is weak, the adsorption plate needs to be disassembled and cleaned before reuse.

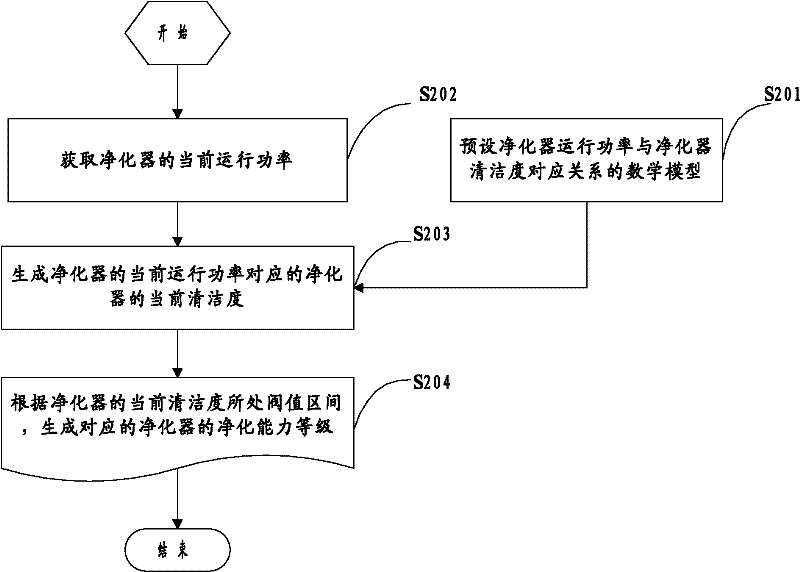

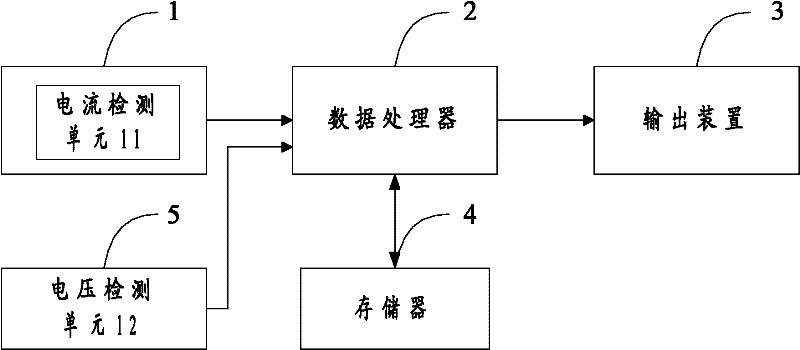

[0030] Therefore, the present invention provides an effective method to detect the cleanliness / purification ability of the purifier, specifically by detecting the change of the operating current (working power) of the oil fume purifier, and establishing a mathematical model to judge the cleanliness of the oil fume purifier (using To characterize the purification ability of the purifier), as a means to remind the purifier user that the purifier needs to be replaced.

[0031] In order to enable those skilled in the art to bett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com