Painting device and associated method

A technique for painting and painting booths, applied in the field of testing and/or assembling painting installations, manufacturing, painting installations for motor vehicle bodies and motor vehicle body parts, which can solve the problems of increasing assembly costs, production stoppages, prolonged Coating equipment installation and adjustment time downtime and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

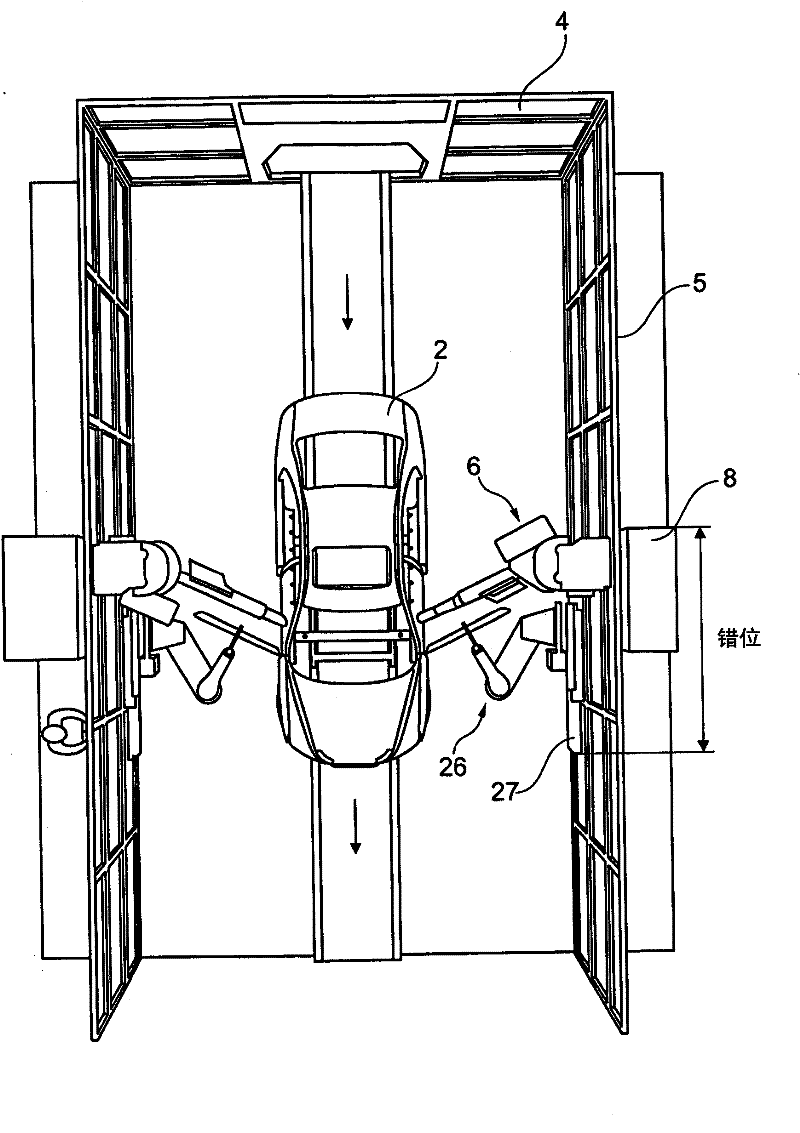

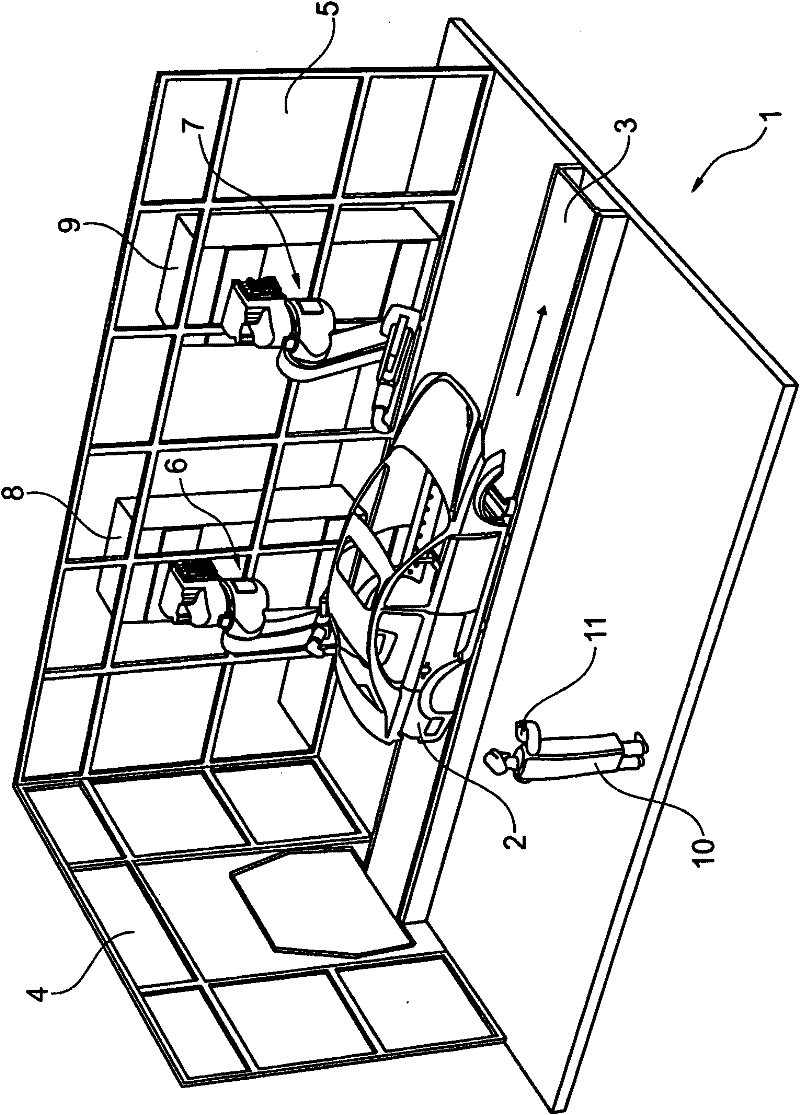

[0081] figure 1 The perspective view in the figure shows a painting booth 1 according to the invention, which is arranged in a painting installation for painting a motor vehicle body 2, wherein the motor vehicle body 2 is conveyed by a conveying device 3 in the direction of the arrow through the painting process Room 1.

[0082] Further painting booths can be arranged upstream and downstream of the painting booth 1 in the conveying direction in order to apply further coating agents to the motor vehicle body 2 . For example, a primer layer can be applied to the motor vehicle body 2 in the paint booth 1 . In a preceding paint booth (not shown), a primer (“primer”) is then applied to the motor vehicle body 2 beforehand. The clearcoat is then applied to the motor vehicle body 2 in subsequent paint booths (not shown) in the conveying direction.

[0083] The paint booth 1 has smooth walls 4 , 5 running around the entire circumference, some of these walls not being shown, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com