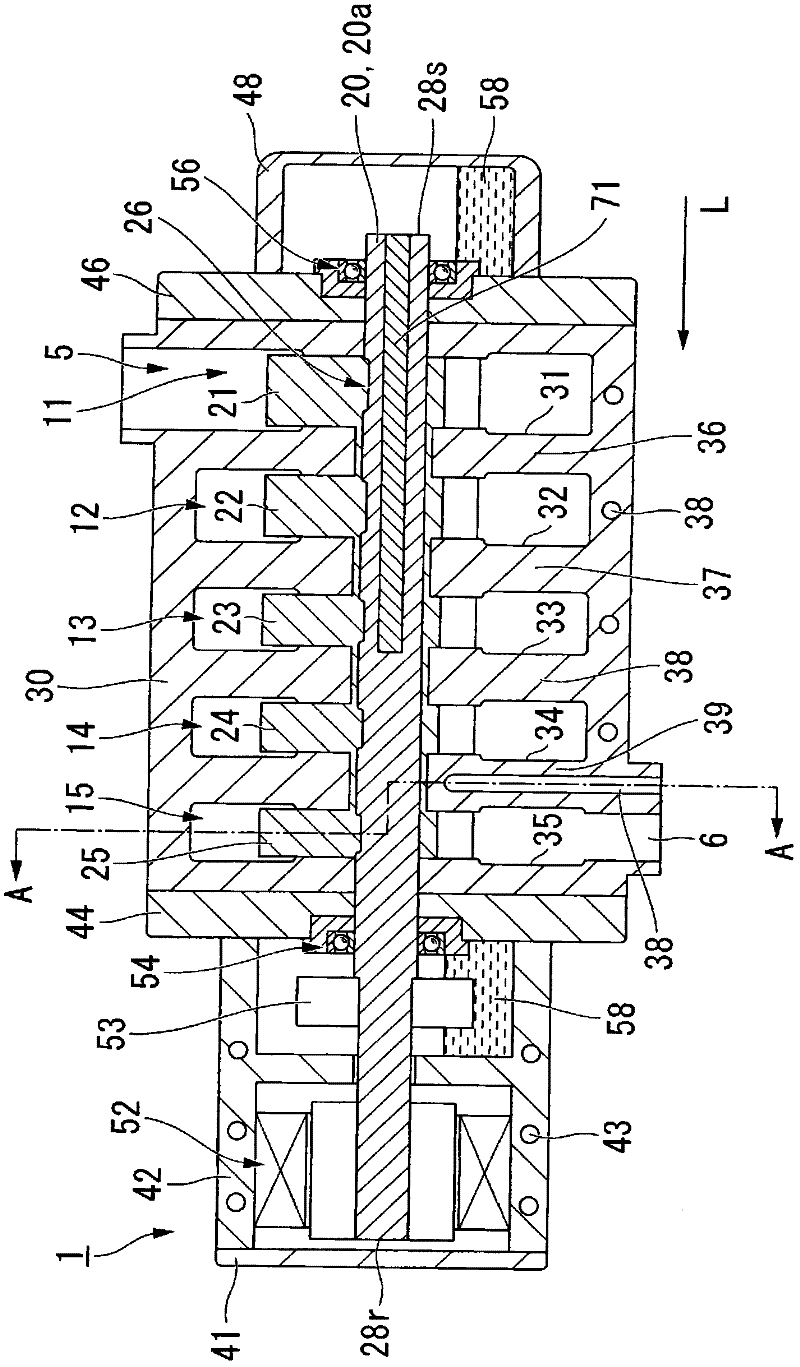

Dry pump

A technology of dry pumps and pump chambers, applied in the field of volume transfer dry pumps, which can solve the problems of reduced exhaust efficiency, temperature difference, deformation and expansion of dry pumps, etc., and achieve the goals of improving exhaust efficiency, eliminating temperature imbalance, and efficient cooling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

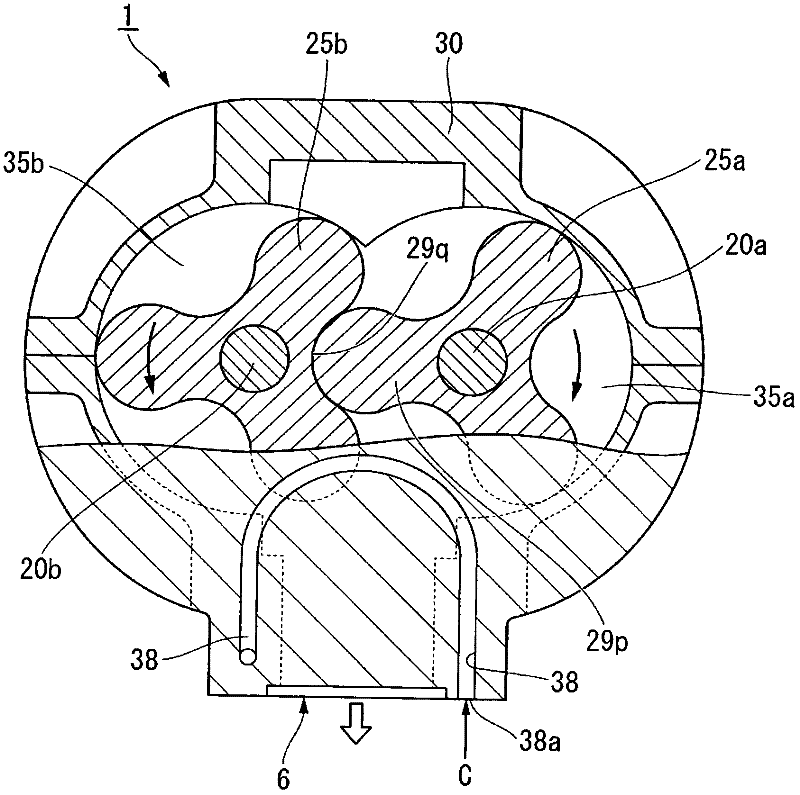

Method used

Image

Examples

Embodiment

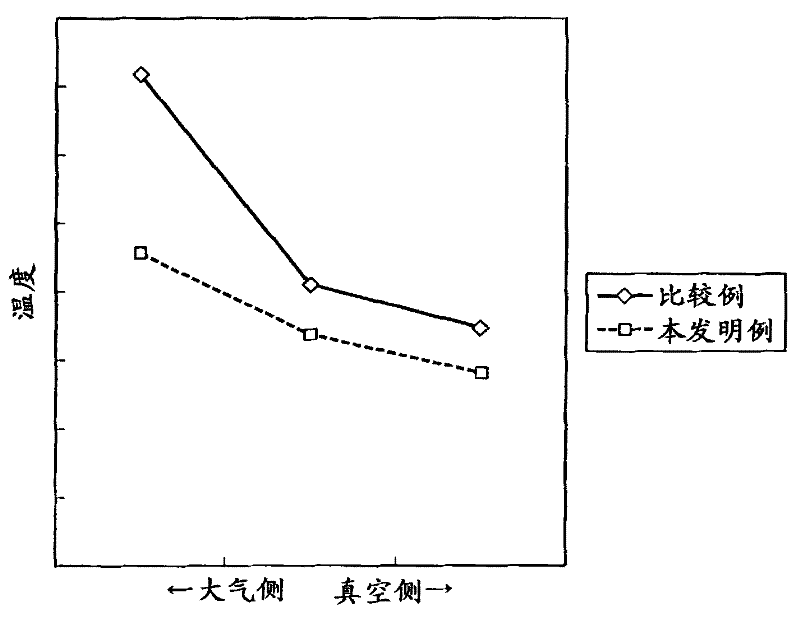

[0042] Examples for verifying the effects of the present invention are shown below. use as figure 1 , 2 The shown dry pump in which the refrigerant passage 35 is formed inside the partition wall 39 to cool the fifth-stage pump chamber 15 on the atmospheric side (discharge side) is an example of the present invention. In addition, as a comparative example, a conventional dry pump in which no refrigerant passage is particularly formed in the partition wall defining the pump chamber on the atmospheric side (discharge side) was used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com