Main mould transmission device for channel profile steel bending machine

A technology of a transmission device and a bending machine is applied in the field of the main mold transmission device of a channel section steel bending machine, which can solve the problems of low degree of automation, high labor intensity of workers, low work efficiency, etc., so as to improve production efficiency, reduce labor intensity of workers, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific drawings and embodiments.

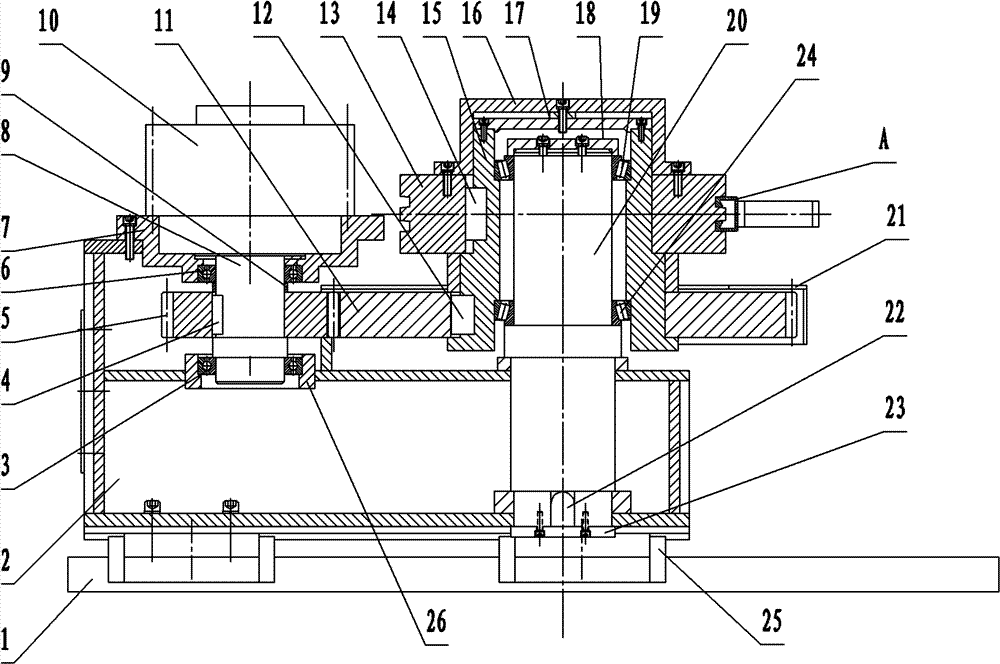

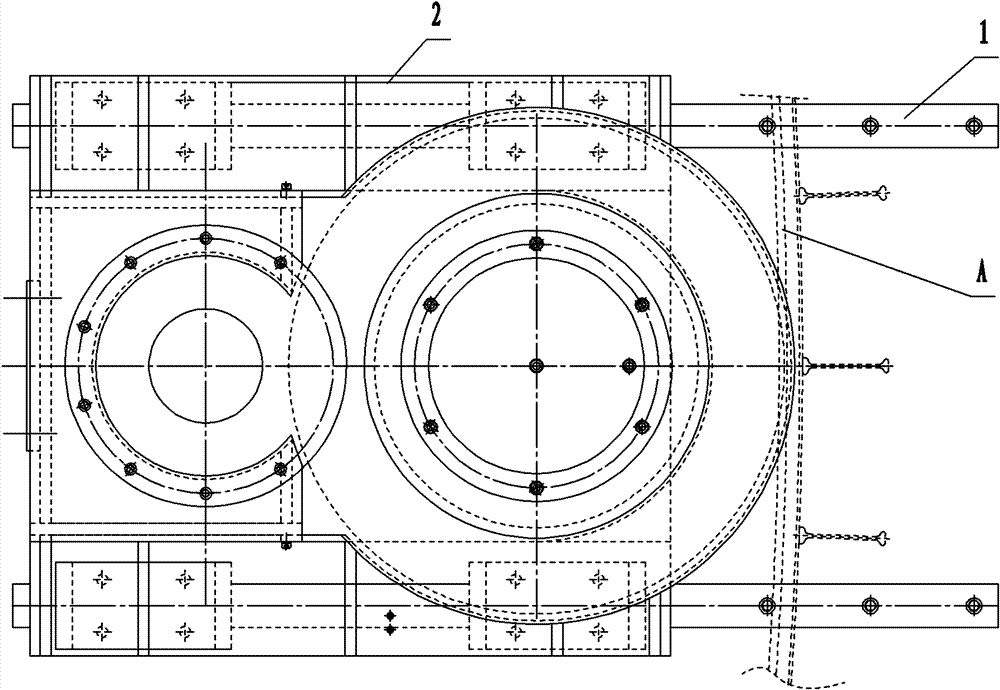

[0016] As shown in the figure: the transmission device of the main mold of the channel section steel bending machine according to the present invention is mainly composed of a linear guide rail 1, a moving body 2, an active lower bearing 3, a flat key 4, a pinion 5, an active upper bearing 6, and a motor seat 7 , driving shaft 8, spacer sleeve 9, driving motor 10, large gear 11, flat key 12, main mold 13, flat key 14, mold sleeve 15, compression cover 16, mold sleeve end cover 17, locking cover 18, passive Parts such as upper bearing 19, passive shaft 20, cover plate 21, flat key 22, end cover 23, passive lower bearing 24 and slide block 25 are formed.

[0017] Such as figure 1 , figure 2 As shown, a slider 25 is set on the linear guide rail 1, and the moving body 2 is fixedly mounted on the slider 25 by screws, and the moving body 2 can slide freely on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com