Flexible side drawing device for forming panel veneer

A sheet metal and flexible technology, applied in the field of flexible edge pulling devices for sheet metal forming, can solve the problems of uneven metal flow, uneven distribution of blank holder force, and thinning of wall thickness, so as to save design and manufacturing costs, draw The effect of uniform distribution of edge force and shortening the development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

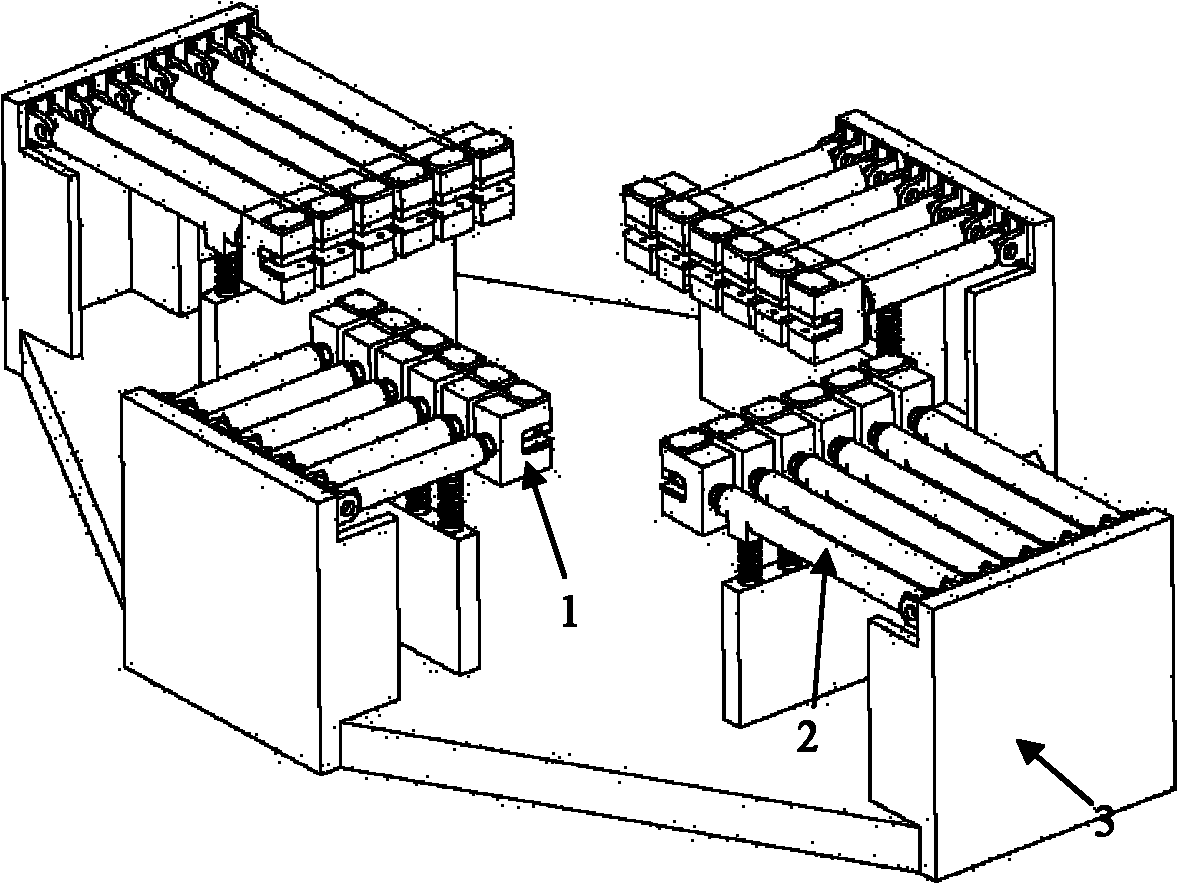

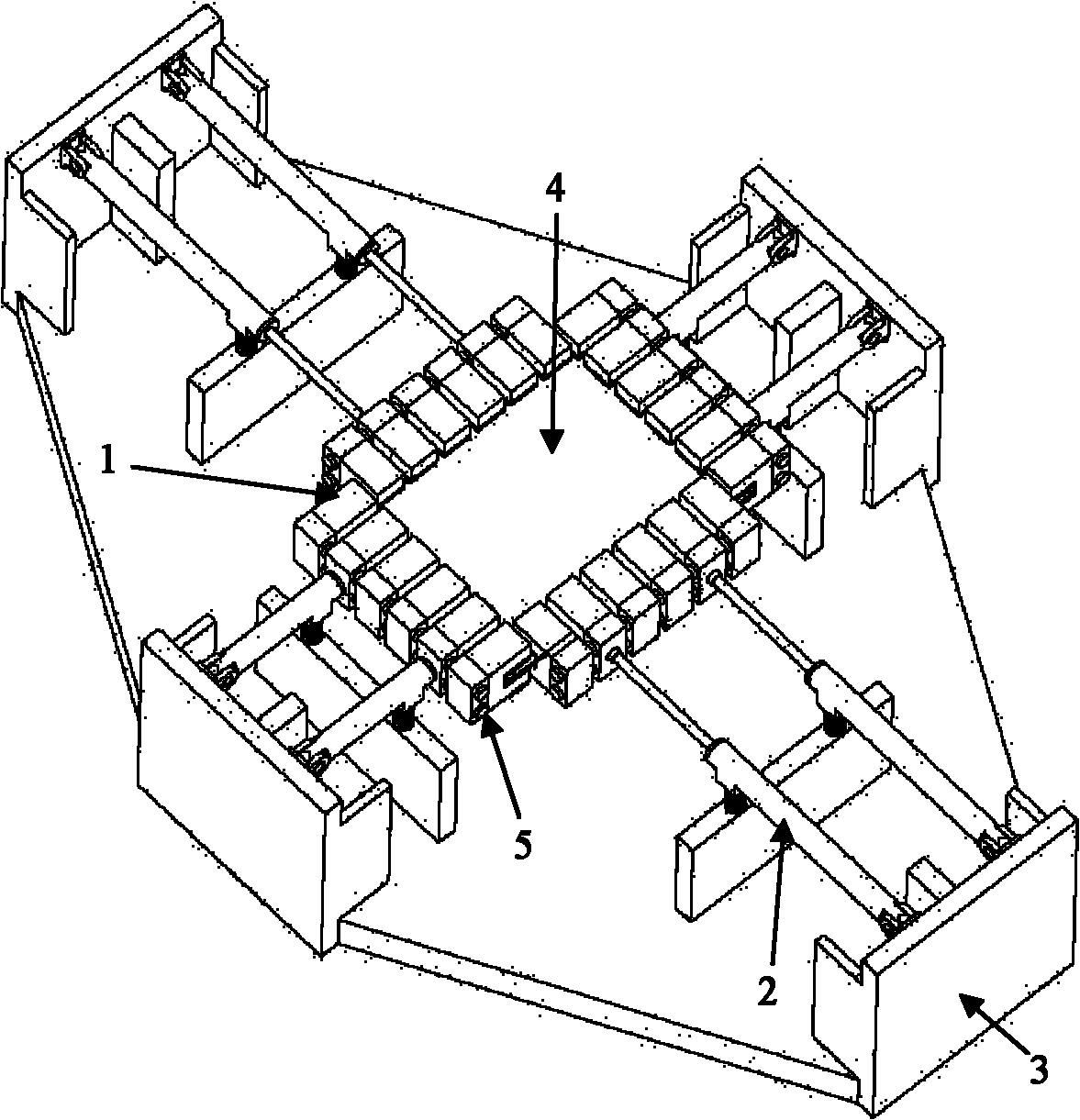

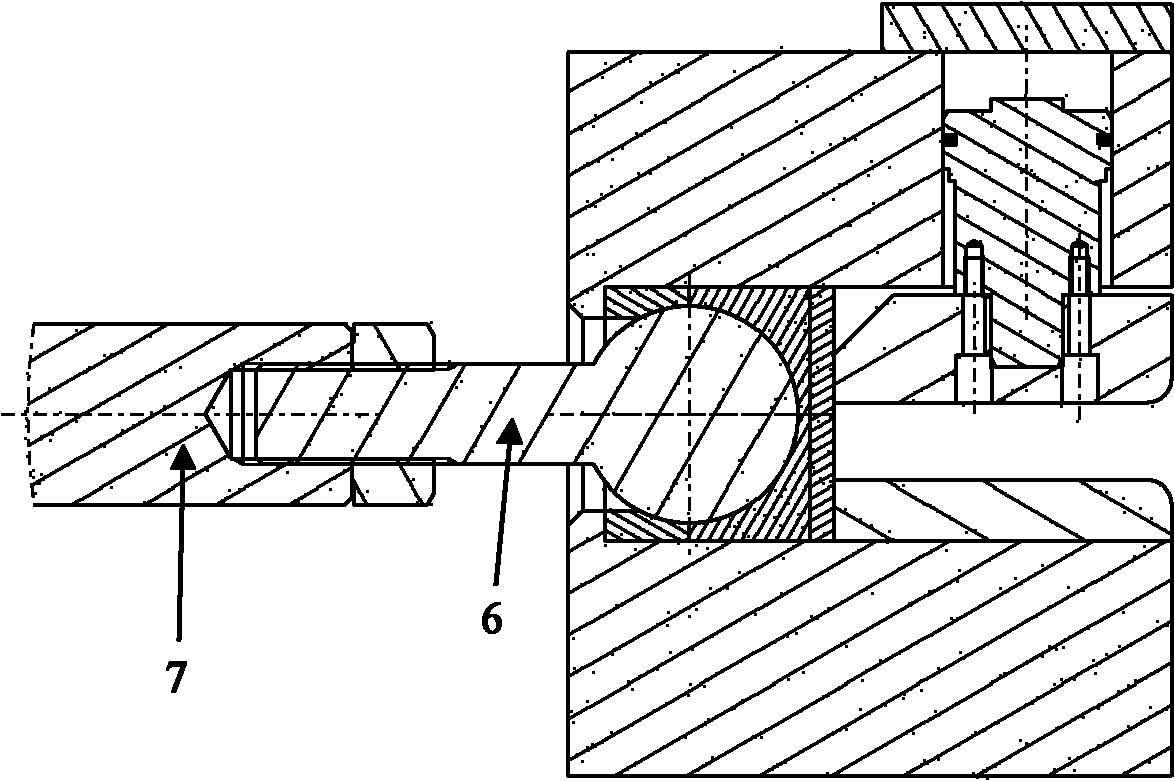

[0029] In order to suppress defects such as wrinkling and cracking of the sheet metal caused during the forming process of the curved surface of the sheet metal, the present invention is realized through the following technical solutions: the flexible edge pulling device for sheet metal forming of the present invention mainly consists of a plurality of clamping mechanisms 1 , a plurality of pulling mechanisms 2 and a support frame 3; a plurality of clamping mechanisms 1 are clamped around the sheet 4 to be processed, and a plurality of pulling mechanisms 2 apply edge pulling forces in different directions of the sheet 4. The size of the pulling edge force is adjustable, and its value is determined by the size and shape of the formed part. The pulling mechanism 2 is composed of hydraulic cylinders arranged in the horizontal direction. The piston end of each hydraulic cylinder is connected with the clamping mechanism 1, and the cylinder end is hinged with the support frame 3; one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com