Automatic pushing and positioning device

A positioning device and automatic technology, which is applied in the direction of grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of increased processing costs and achieve the effects of high processing costs, avoiding large processing errors and long working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

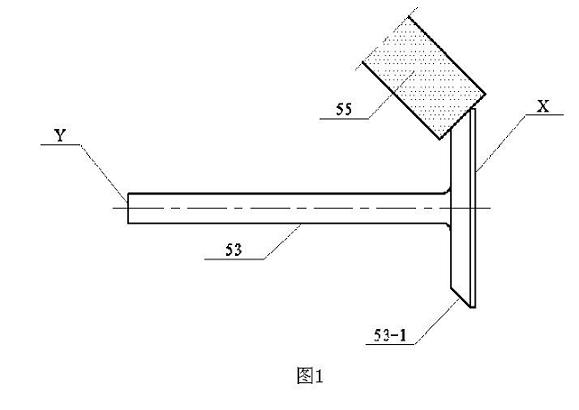

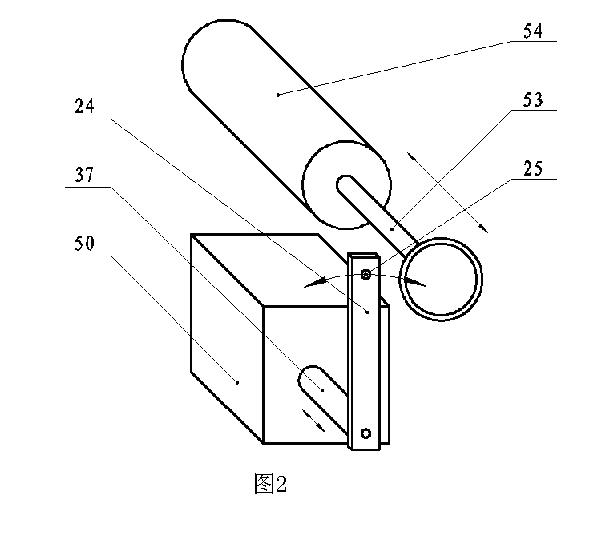

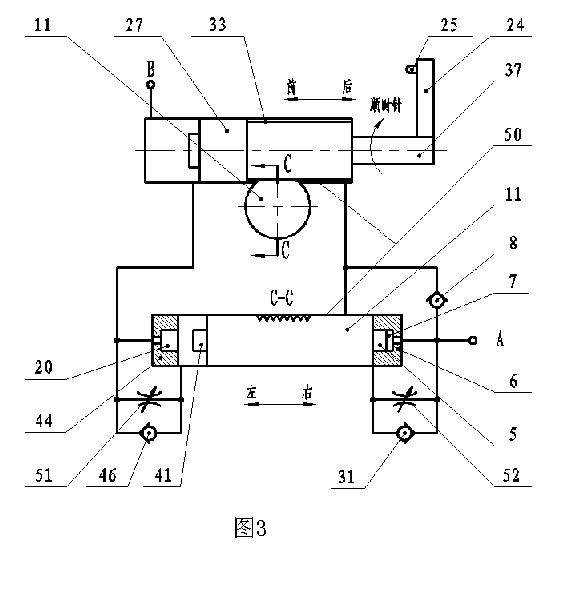

[0028] like Figure 3-5 As shown, the present invention provides an automatic pushing and positioning device, comprising a single-rod hydraulic cylinder and a plunger cylinder, a gear 33 is coaxially arranged between the piston 27 and the piston rod 37 of the single-rod hydraulic cylinder, and the The gear is located in the inner cavity of the cylinder barrel of the single-rod hydraulic cylinder, the piston of the plunger cylinder is a rack plunger 11, and is meshed with the gear, and a swing rod 24 is fixed on the piston rod. The swing rod extends radially of the gear, the swing rod is located outside the cylinder barrel of the single-rod hydraulic cylinder, and the swing rod is provided with a positioning structure 25 for component positioning.

[0029] The gear and the piston or piston rod are integrally structured, or may be rigidly connected or rotatably connected.

[0030] The automatic pushing and positioning device can realize linear reciprocating motion in one direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com