Feeding device for plate pressing device

A technology of feeding device and plate, applied in clay preparation device, mixing operation control device, mixing operation control and other directions, can solve the problems of plate quality and different components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

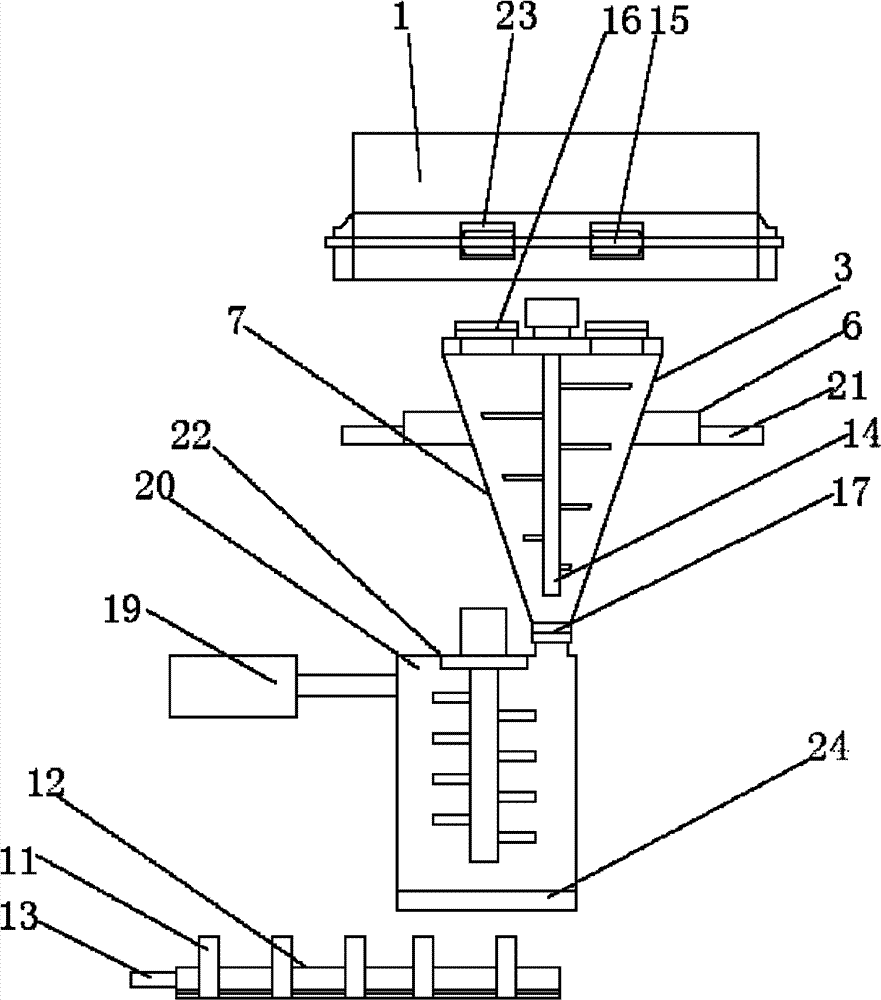

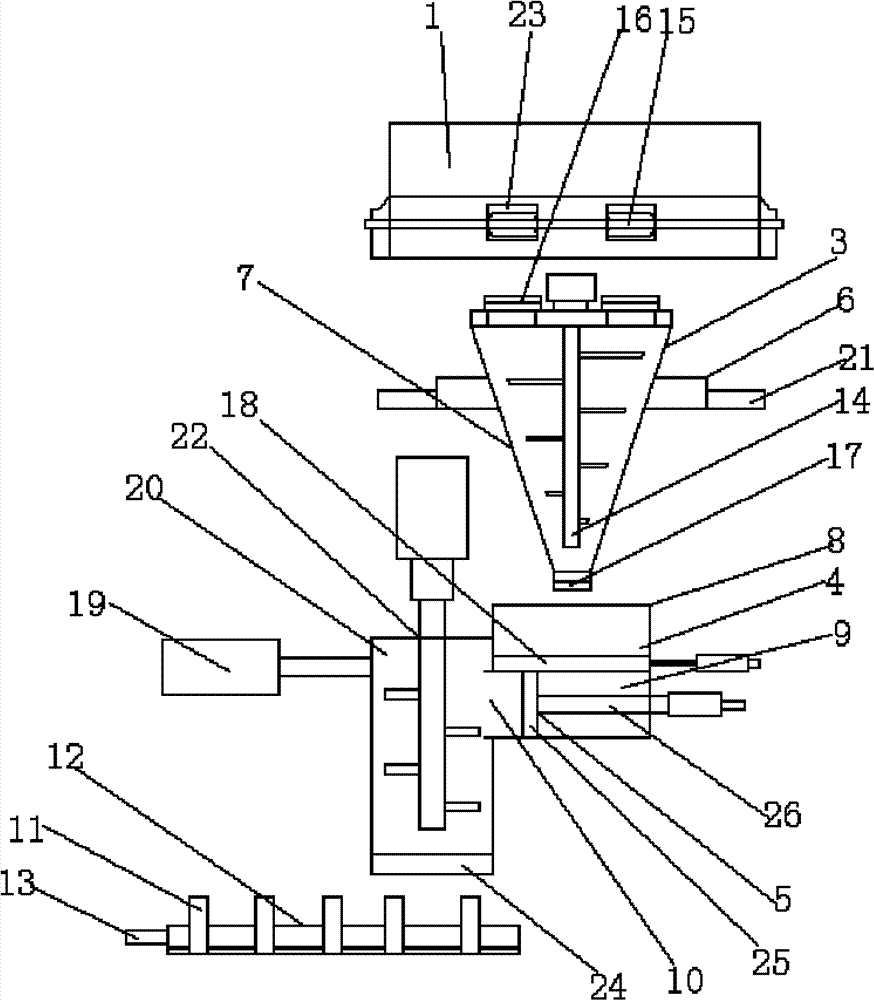

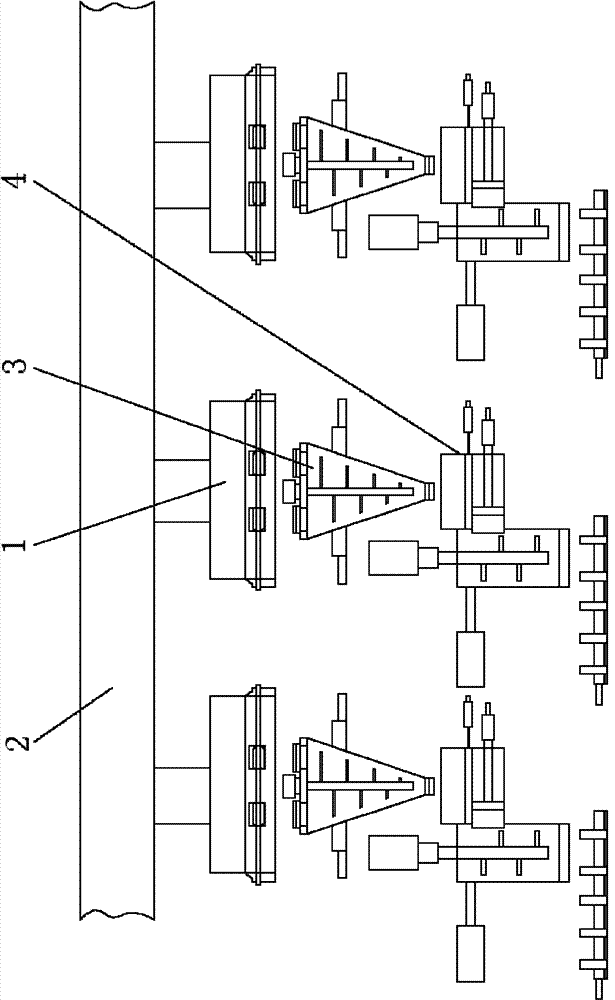

[0020] refer to figure 1 A feeding device for a plate pressing device is shown, which includes a silo 1 for holding uniformly mixed dry materials, a weighing device 3, and a device for receiving slave weighing devices arranged below the weighing device 3 3 Output dry material and water injection stirring device 22 for injecting and stirring the dry material. The weighing device 3 is provided with a feed valve 16 and a discharge valve 17. The silo 1 is provided with a silo feeding device. The port 23 corresponds to the feed valve 16 of the weighing device 3, and the discharge port 24 of the water injection stirring device is correspondingly provided with a discharge device.

[0021]As a further improvement of the present invention, in order to enable the material in the silo 1 to be transported to the weighing device 3 along the outlet, the silo feeding device is a screw feeding device 15; in order to prevent the material from entering the water injection stirring device 22 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com