Front-end module carrying frame of car

A front-end module and carrier technology, which is applied in the direction of vehicle components, upper structure, upper structure sub-assembly, etc., can solve the problems that the overall strength is difficult to meet the requirements, the installation process of inevitable parts is unavoidable, and the design requirements cannot be effectively met. , to achieve the effect of meeting light weight requirements, ensuring installation accuracy, and improving overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in detail below in conjunction with accompanying drawing:

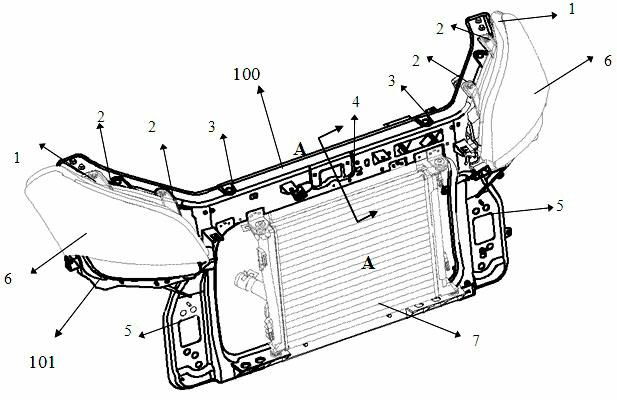

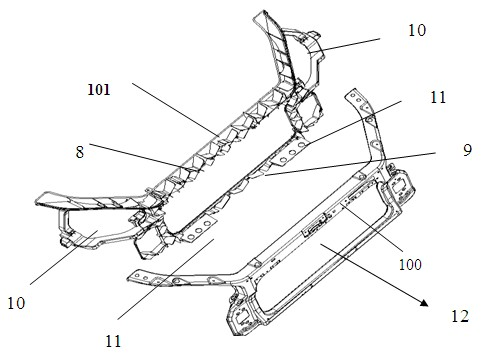

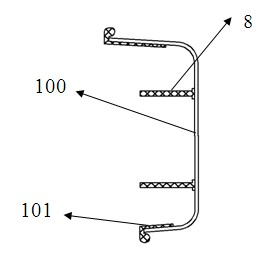

[0014] see figure 1 , figure 2 and image 3 The shown automotive front-end module carrier includes a sheet metal part 100 and a plastic part 101. The sheet metal part and the plastic part are integrated by injection molding to improve the overall strength and reduce the weight while ensuring the same strength.

[0015] A front cover lock installation hole 4 is provided near the middle part of the upper beam of the sheet metal part 100, and two mutually symmetrical front cover buffer block installation holes 3 are arranged at the middle part of the upper beam of the sheet metal part 100. The left and right parts of the beam are respectively provided with two headlight mounting holes 2, and the left end and the right end of the beam on the sheet metal part 100 are respectively provided with mutually symmetrical first mounting holes 1, near the sheet metal part 100 The left a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com