Connecting structure of end wall, side wall and hopper ridge for hopper car

A connection structure and funnel car technology, which is applied in the direction of funnel cars, transport passenger cars, railway car bodies, etc., can solve the problems of reducing connection strength, limited capacity of side wall load, limited support force, etc., to improve connection strength and load bearing Ability to eliminate the effect of stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

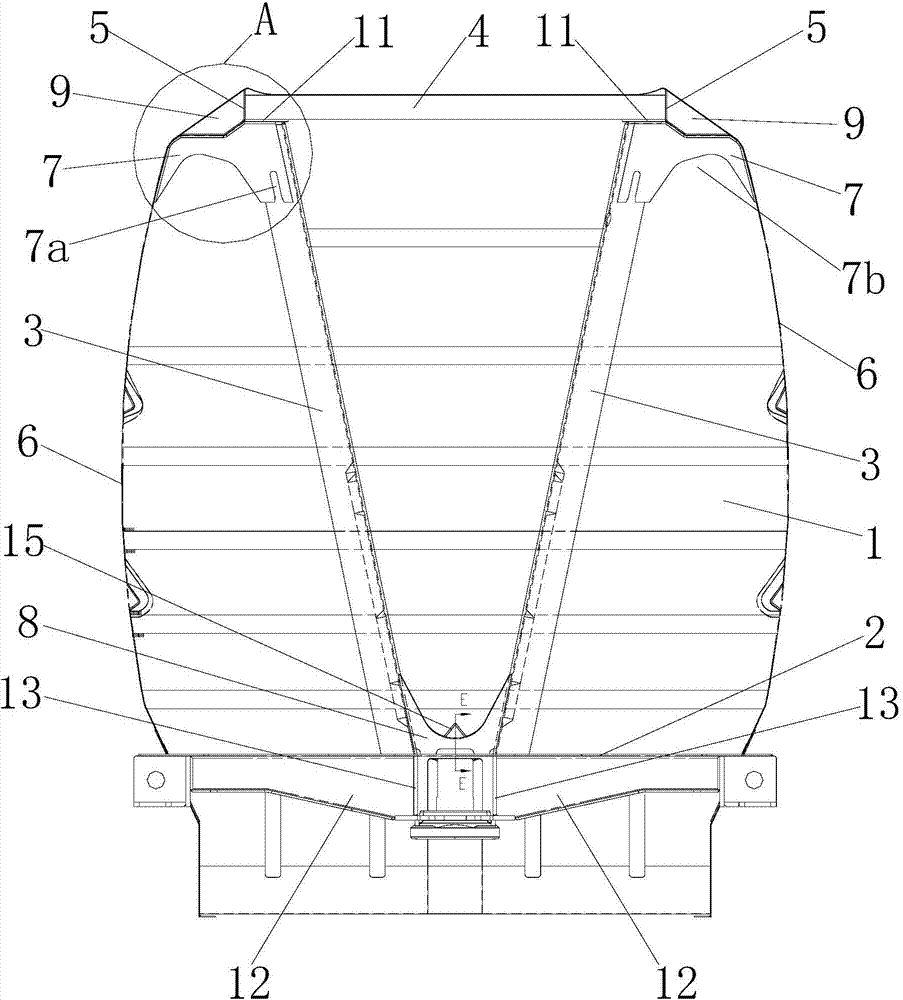

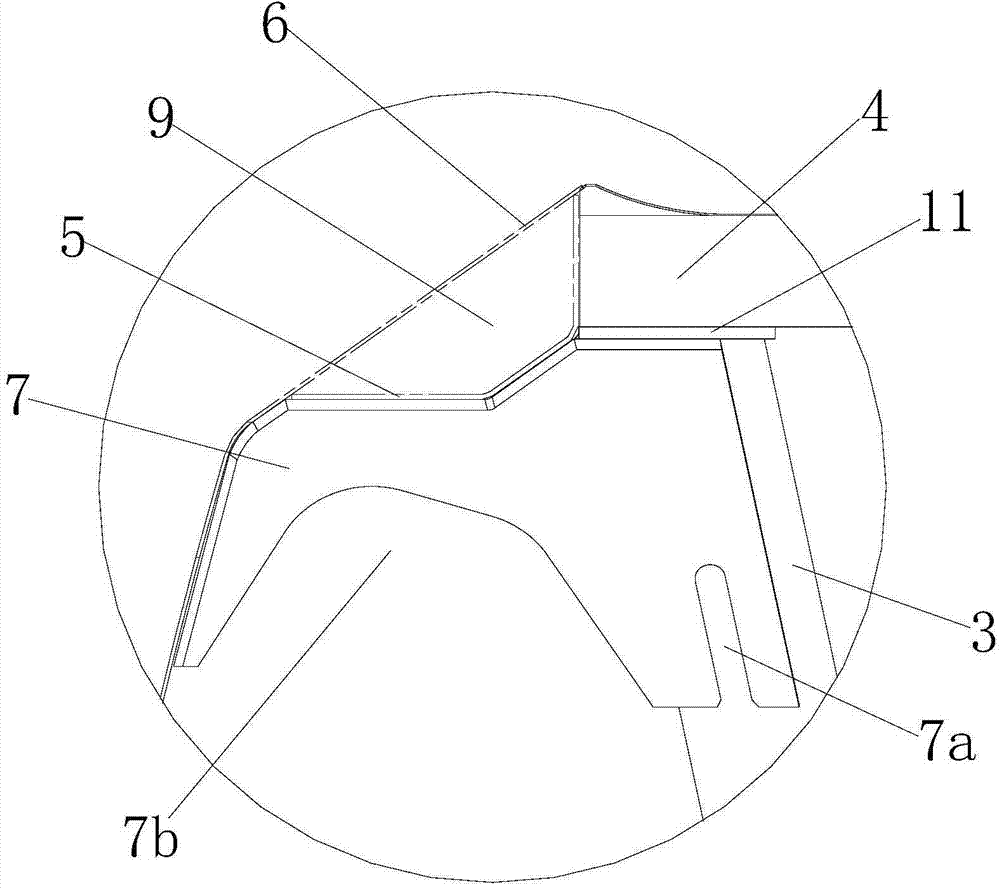

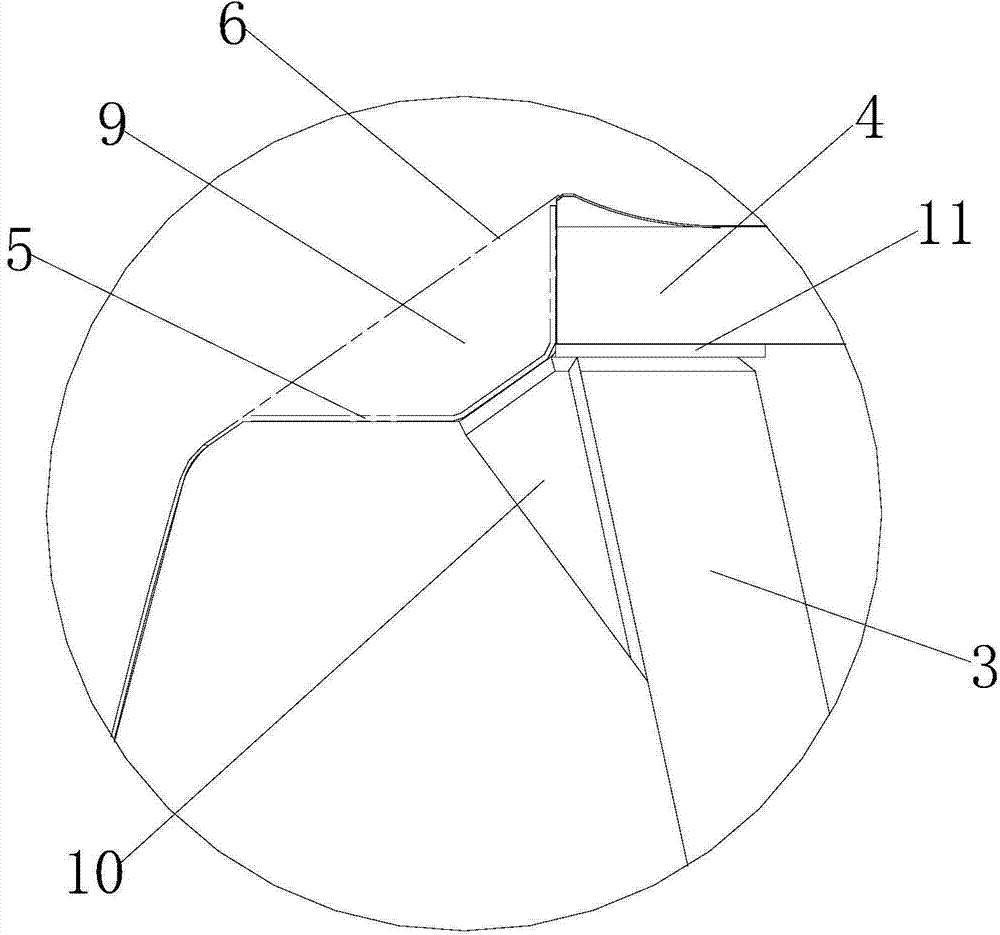

[0074] Such as figure 1The shown connection structure for the end wall, side wall and funnel ridge of a funnel car includes an end wall 1, a floor 2, a partition 3, an upper end beam 4, an upper side beam 5, a side wall 6, a first ridge Plate 16 and upper funnel back 17, the lower ends of the two partitions 3 are connected to the floor 2 respectively, the sides of the two partitions 3 are connected to the side walls of the end wall 1 respectively, and the two partitions are connected to each other. The upper ends of the partitions 3 are respectively connected to the bottom surfaces of the upper end beams 4, the two upper end beams 4 and the two upper side beams 5 are directly spliced into a frame structure, and the side walls 6 are covered on the upper On the side beam 5, an upper connection plate 7 is connected between the side wall 6 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com