Corner longitudinal reinforcement centralized and profiled bar built-in reinforcing structure of RC (Reinforced Concrete) rectangular column and preparation method thereof

A technology for strengthening structures and rectangular columns, applied in the directions of columns, piers, pillars, etc., can solve the problems of interlayer collapse of reinforced concrete frame structures, failure to achieve the design goals of "strong columns and weak beams, and failure to consider the multi-dimensionality of ground vibration input." , to achieve good strengthening effect, ensure authenticity and economy, and enhance the effect of gripping force and restraint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

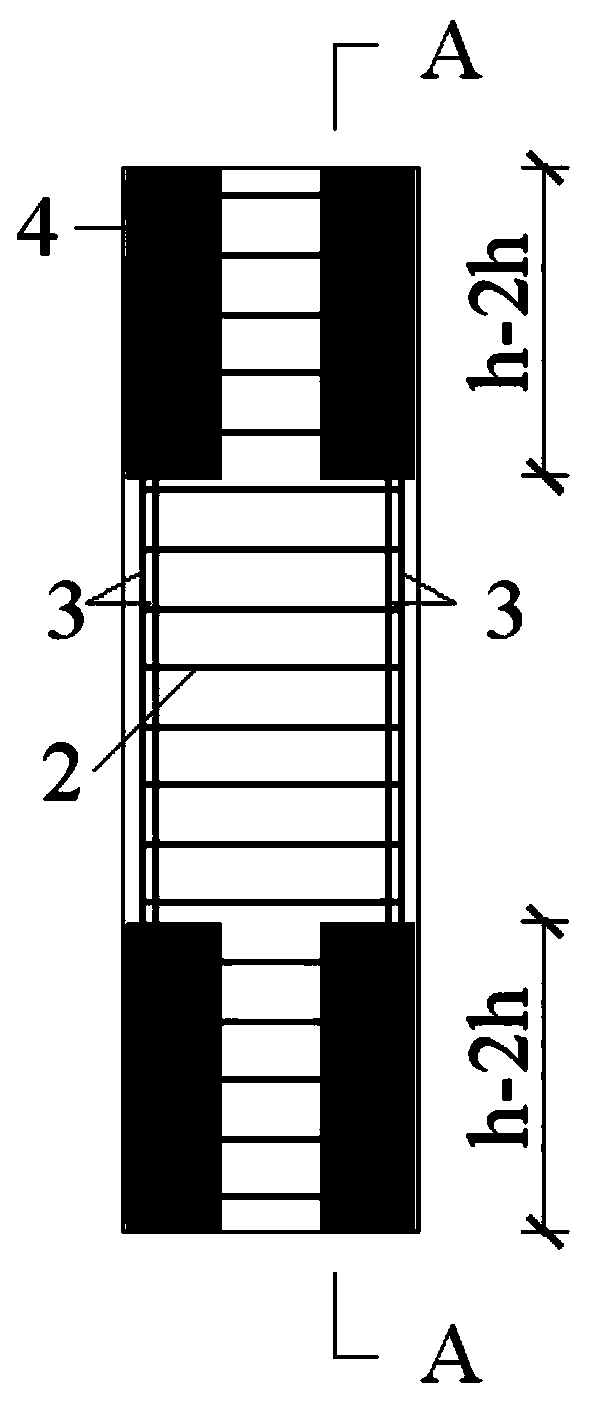

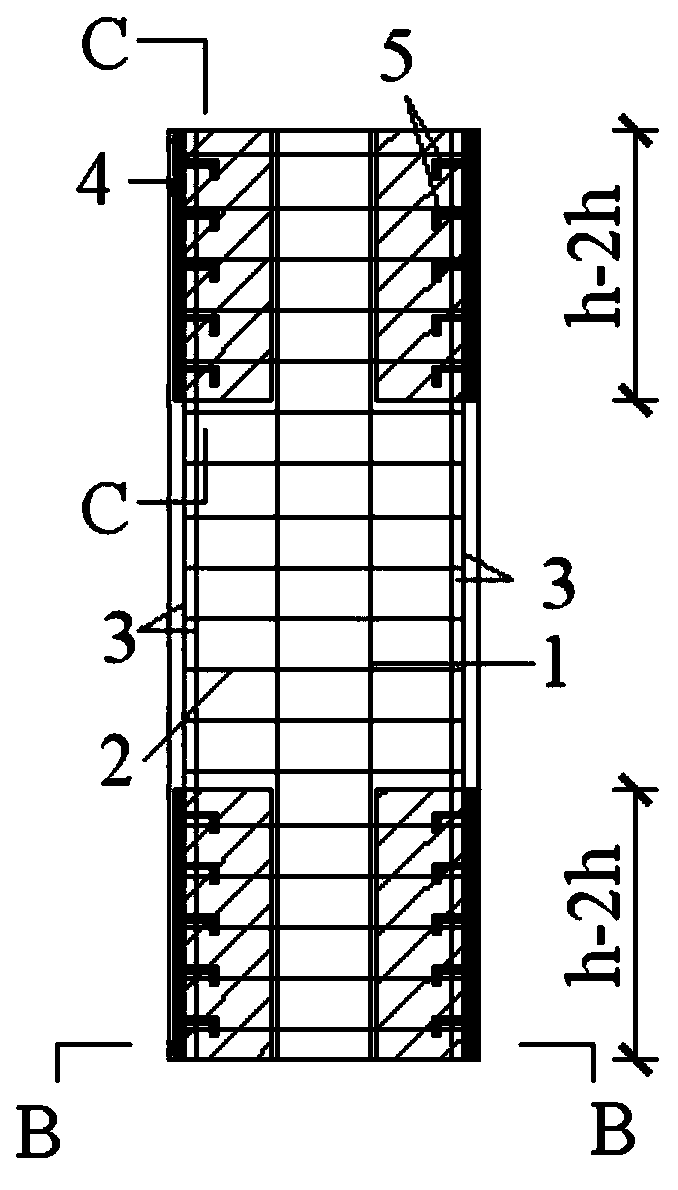

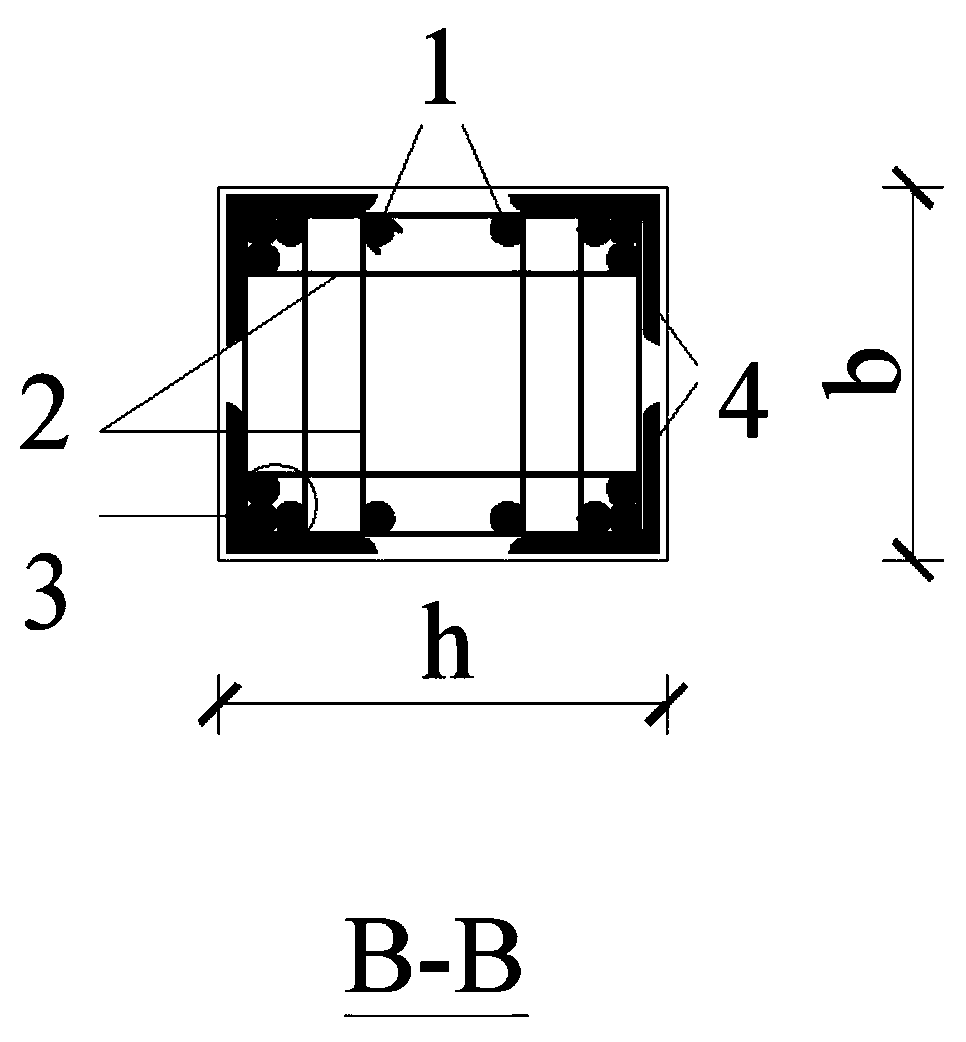

[0028] An RC rectangular column corner longitudinal reinforcement concentrated built-in shaped steel reinforcement structure, characterized in that it includes a reinforcement cage, which is formed by binding and fixing the RC column longitudinal reinforcement 1, stirrup reinforcement 2, and isosceles right-angled triangular character-shaped longitudinal reinforcement 3, It also includes angle steel 4 and steel bar 5; the cross-section of the RC column adopts a rectangle; the longitudinal reinforcement 1 of the RC column refers to all longitudinal reinforcements except the longitudinal reinforcement 3 of the isosceles right triangle; the isosceles right triangle Pin-shaped longitudinal reinforcement 3 refers to: the four corners of the RC column section, on the two sides adjacent to each corner, each longitudinal reinforcement adjacent to the corner reinforcement is concentrated to the corner reinforcement position at the same time. After concentration, the three longitudinal re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com