Frequency-conversion traction equipment energy-saving system for elevator

An energy-saving system and traction technology, applied in the field of elevator energy-saving control, can solve the problems of the normal operation of the inverter busbar voltage rising, affecting the safe and stable operation of the power supply grid, and the impact of the power grid, achieving obvious energy-saving effect, safe, stable and reliable work. The effect of avoiding distractions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

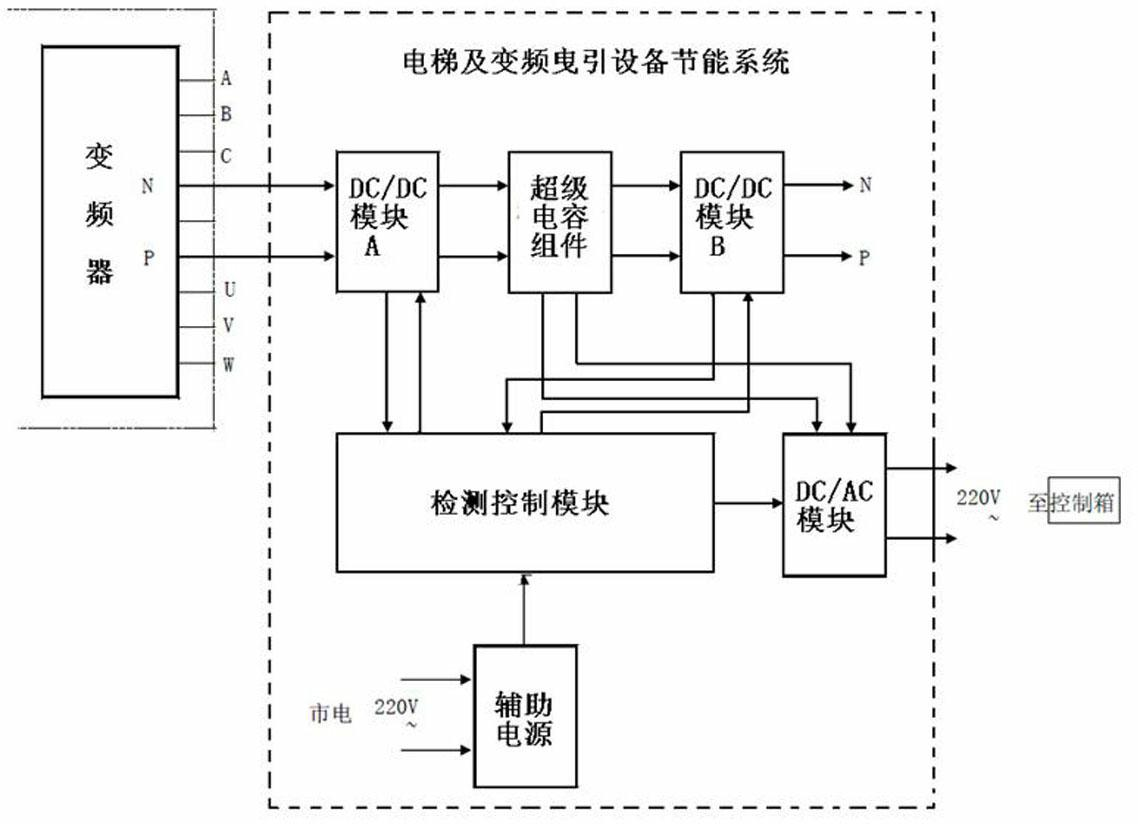

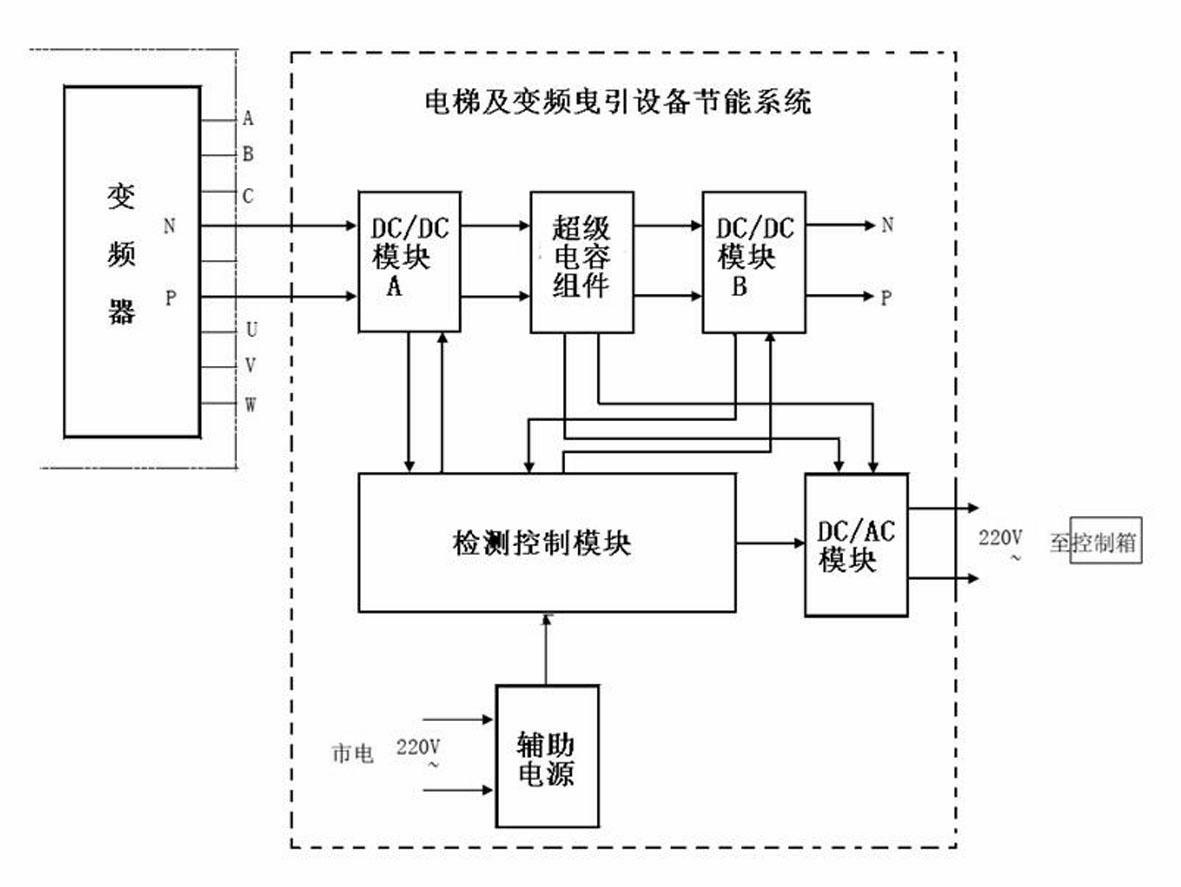

[0020] like figure 1 The energy-saving system for frequency conversion traction equipment for elevators includes: DC / DC module A, supercapacitor assembly, DC / DC module B, detection control module, auxiliary power supply, DC / AC module and control box; frequency conversion traction equipment for elevators The lead equipment energy-saving system is connected with the frequency converter.

[0021] The connection relationship of the above components is as follows: the frequency converter is electrically connected to the DC / DC modules A and B in the energy-saving system of the frequency conversion traction equipment for elevators; the DC / DC module A is electrically connected to the supercapacitor assembly; the supercapacitor assembly is respectively connected to the DC The / DC module B is electrically connected to the DC / AC module; the detection control module is connected to the DC / DC module A and DC / DC module B to detect the terminal voltage of the supercapacitor component; and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com