Hand operated grinding mill

A winching and hand-cranking technology, which is applied in hoisting devices, clockwork mechanisms, etc., can solve the problems of no safety ratchet protection, affecting maintenance work efficiency, and low rope-laying efficiency, achieving reasonable improvement in appearance and structure, and rope The effect of easy insertion and portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

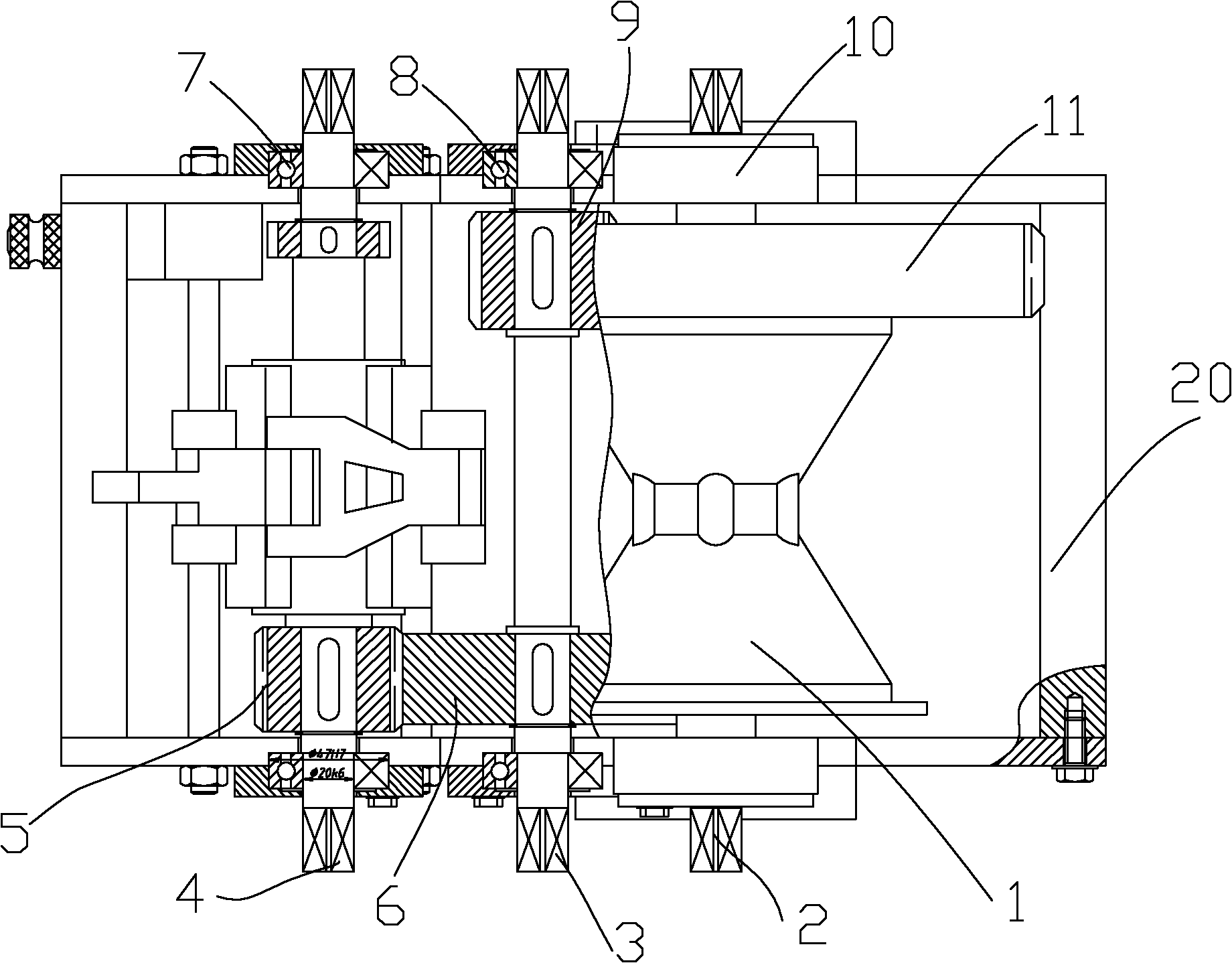

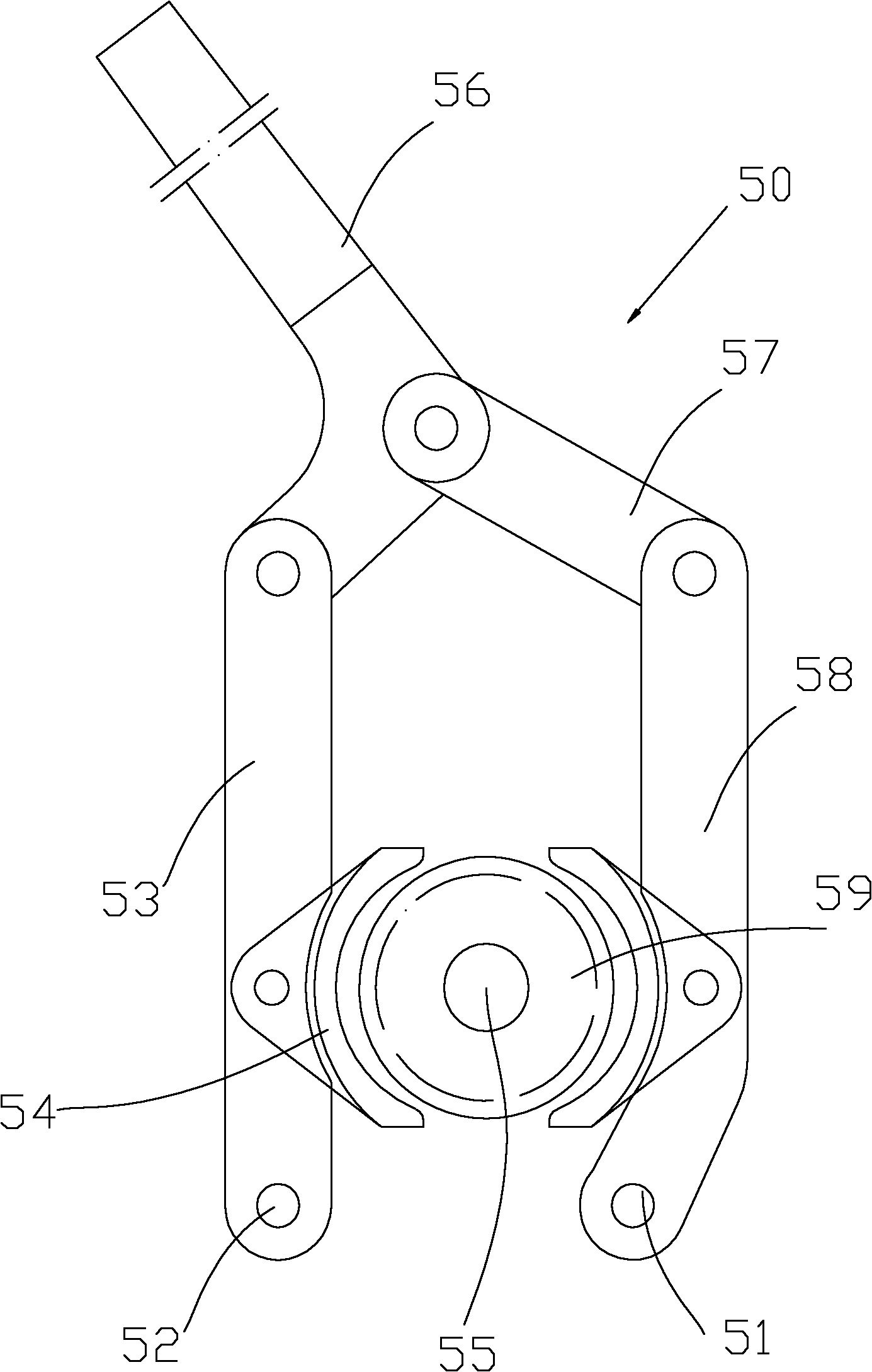

[0017] see figure 1 , image 3 and Figure 4 As shown, the hand winch includes a hand winch main body 30 and its supporting rocker arm 40. The hand winch main body includes a winch 20, and pinion shafts 4 are arranged side by side on the two ends of the winch 20. , the middle gear shaft 3, on the middle gear shaft 3 top, the winch 20 is provided with the grinding mandrel 2; take the grinding mandrel 2 as the center shaft to be provided with the large gear 11 and the grinding core 1, and the middle gear shaft 3 as The two ends of the center shaft are provided with a second pinion 9 and a middle gear 6, with the pinion shaft 4 as the center shaft, a first pinion 5 is arranged, the bull gear 11 and the second pinion 9 mesh with each other, and the middle gear 6 Mesh with the first pinion 5; on the main body 30 of the hand winch, there is also a multi-link mechanism 50 for providing reverse resistance when the winch is unwound.

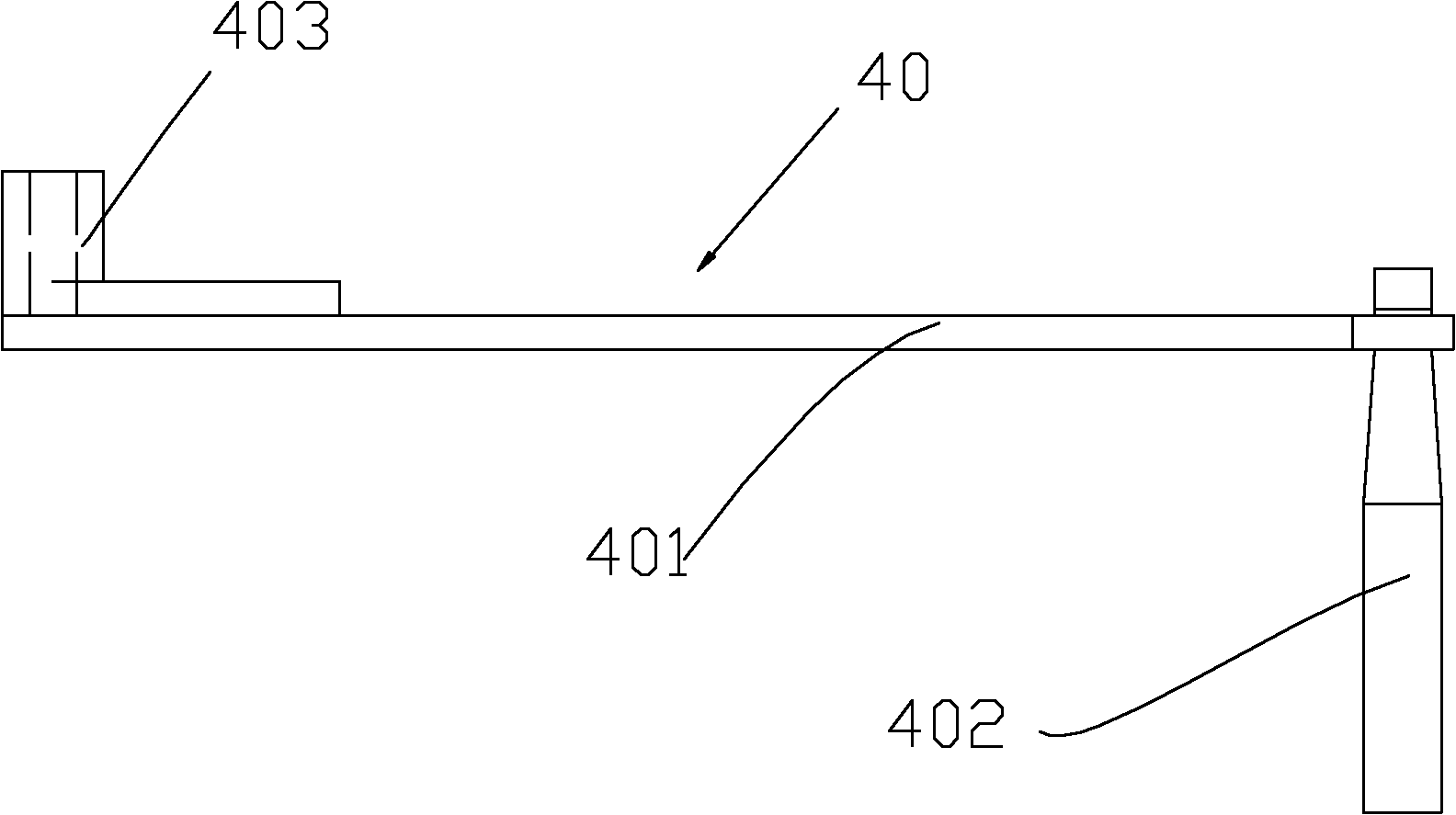

[0018] see figure 2 As shown, the rocker arm 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com