Method for preparing liquor by utilizing termite nests

A termite nest and termite technology, applied in the field of liquor brewing technology, can solve the problems of low dissolution rate of active ingredients, poor fermentation residue treatment, large waste of nutrients, etc., and achieve the effects of increasing dissolution surface area, enriching nutritional value and high value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

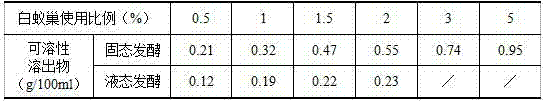

Examples

Embodiment 1

[0018] Saccharification: Take 100 kg of rice as raw material, soak it in water, add 200 kg of water to boil it into a thick porridge, add 0.1 kg of amylase, add 0.1 kg of glucoamylase when the temperature drops to 50~60°C, and then add 25 kg of termite nest Stir evenly, keep warm and saccharify for 72 hours to obtain mash. The termite nest is processed by using the termite nest of the black-winged soil termite. The termite nest is dehydrated, dried, crushed, and impurities are removed, and then sterilized. In addition, the sugar content in the mash should be 20-30% to ensure the hyperosmotic effect of the sugar.

[0019] Fermentation: Mix the saccharified mash into the wine grains stored in cellars or pottery vats, add koji and mix well, compact and seal, turn over the grains after 15 days of fermentation, and ferment for another 15 days; the amount of koji added is 2.5% of the mass of rice %, the fermentation adopts the traditional solid-state fermentation process of liquor,...

Embodiment 2

[0023] Saccharification: Take 100 kg of rice as raw material, soak it in water, add 200 kg of water to boil it into a thick porridge, add 0.08 kg of amylase, add 0.08 kg of glucoamylase when the temperature drops to 50~60°C, then add 20 kg of termite nest and stir Evenly, heat preservation and saccharification for 72 hours to obtain mash. The sugar content in mash should be more than 20%.

[0024] Fermentation: Mix the saccharified mash into the wine grains stored in the cellar or ceramic vat, add koji and mix well, compact and seal, turn over the grains after 30 days of fermentation, and ferment for another 30 days; the amount of koji added is 2% of the mass of rice %, the fermentation adopts the traditional solid-state fermentation process of liquor, and the fermentation temperature is controlled at 28-35°C. In the fermentation stage, double-round bottom fermentation is adopted to fully release the nutrients in the termite nest.

[0025] Juice extraction: Put the fermented...

Embodiment 3

[0028] Saccharification: Take 100 kg of rice as raw material, soak it in water, add 200 kg of water to boil it into a thick porridge, add 0.12 kg of amylase, add 0.12 kg of glucoamylase when the temperature drops to 50~60°C, and then add 30 kg of termite nest Stir evenly, keep warm and saccharify for 72 hours to obtain mash. The termite nest is processed by using the termite nest of the yellow-winged termite. The termite nest is dehydrated, dried, crushed, and impurities are removed, and then sterilized. In addition, the sugar content in the mash should be 20-30% to ensure the hyperosmotic effect of the sugar.

[0029] Fermentation: Mix the saccharified mash into the wine grains stored in pits or pottery vats, add koji and mix well, compact and seal, turn over the grains after 15 days of fermentation, and ferment for another 15 days; the amount of koji added is 8% of the mass of rice %, the fermentation adopts the traditional solid-state fermentation process of liquor, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com