Pattern manufacturing method and weaving system for textile

A production method and fabric technology, applied in textiles and papermaking, fabrics, textiles, etc., can solve the problems of red lines and yellow lines not being fused, and achieve the effect of clearly identifiable patterns, clear colors, and clear outlines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings and the embodiments.

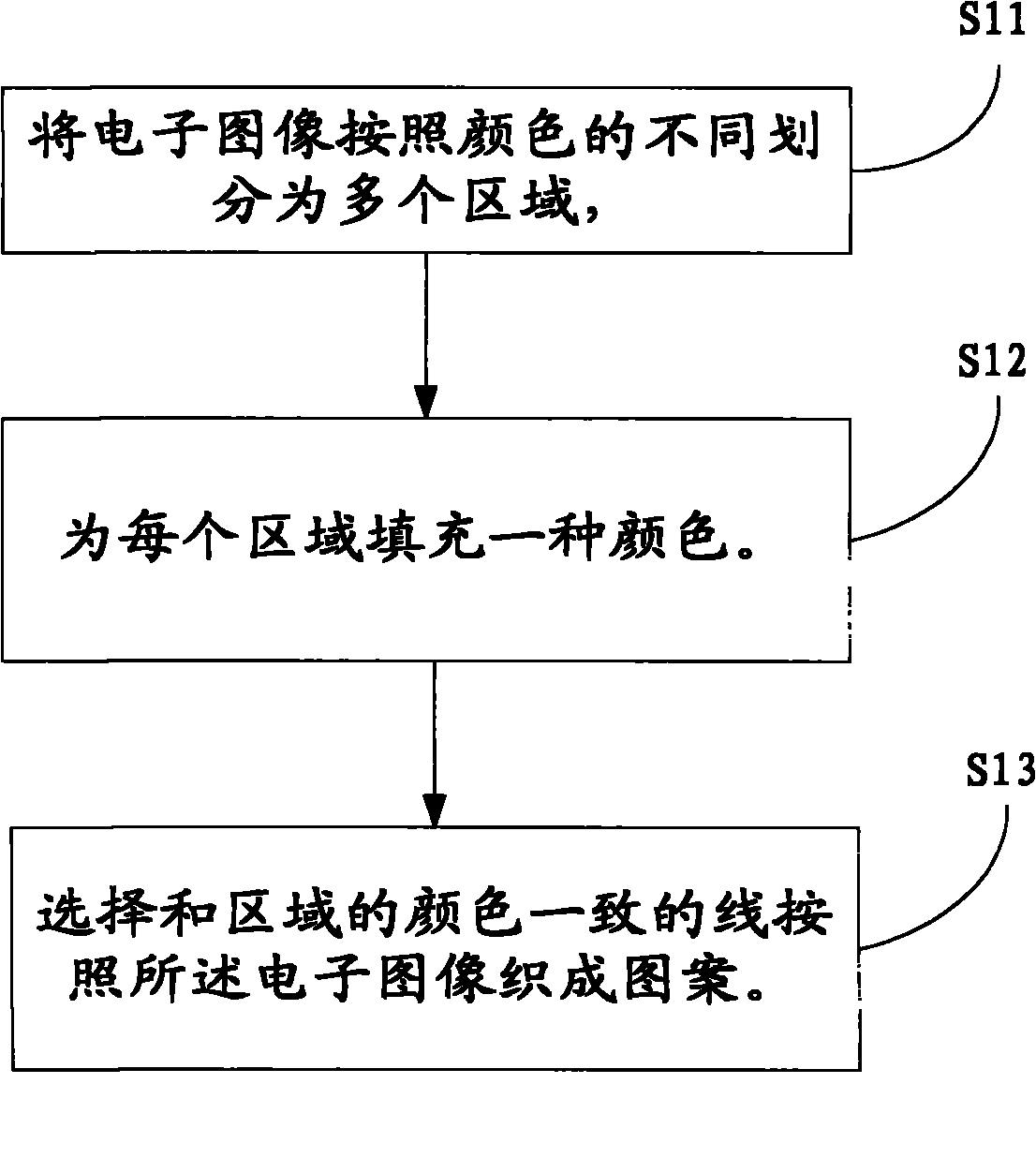

[0025] See image 3 , The first embodiment includes the following steps:

[0026] S11: Divide the electronic image into multiple regions according to different colors, wherein the adjacent pixels whose color change is less than the tolerance are divided into the same area, and the adjacent pixels whose color change is not less than the tolerance are divided into different regions. The area.

[0027] During the division process, all pixels in the image can be traversed and the color values of adjacent pixels can be compared. The color value can adopt various commonly used color modes, such as RGB mode, HSB mode, LAB mode or CMYK mode, etc., compare the difference between the color values of adjacent pixels in a color mode, through the difference and tolerance Compare, divide adjacent pixels into the same area or different areas according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com