Fault diagnosis device and method for high-pressure common-rail fuel injection system

A technology of a fuel injection system and a fault diagnosis device, which is applied to a fuel injection device, a measuring device, a charging system, etc., can solve the problems of high software overhead, damage to the engine mechanical structure, and increased software workload, and achieves a simple hardware circuit. , The effect of comprehensive fault types and reliable fault diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation and working principle of the high-pressure oil pump solenoid valve and fuel injector fault diagnosis solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

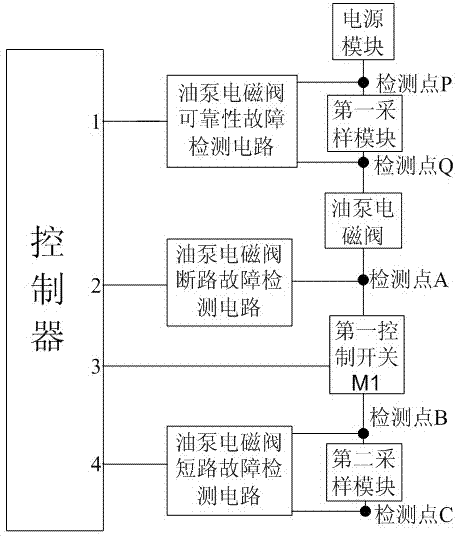

[0022] Such as figure 1As shown, the internal module connection relationship of the oil pump solenoid valve fault detection device is: the controller pin 1 is connected to the oil pump solenoid valve reliability fault detection circuit, and the oil pump solenoid valve reliability fault detection circuit is connected to the detection point P and detection point Q. The detection point P and detection point Q are connected to both ends of the first sampling module, the controller pin 2 is connected to the oil pump solenoid valve open circuit fault detection circuit, the oil pump solenoid valve open circuit fault detection circuit is connected to the detection point A, and the controller pin 3 is connected to the The first control s...

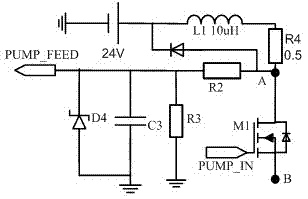

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com