Self-locking nut

A technology of self-locking nuts and nuts, which is applied in the direction of nuts, locking fasteners, screws, etc., can solve the problems of increased processing costs, insufficient locking force, and stress concentration in grooves, so as to improve production efficiency and stress Uniform, avoid stress concentration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

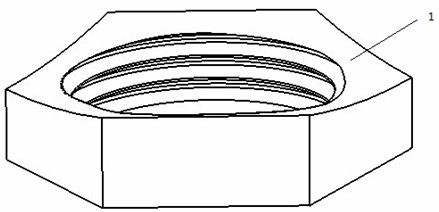

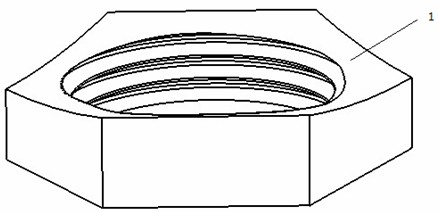

[0011] Such as figure 1 As mentioned above, the self-locking nut includes a nut 1, the edge of the nut is polygonal, and the upper and lower end surfaces of the nut are concave curved surfaces.

[0012] The concave curved surface is a surface of revolution, the center of which is located on the axis of the screw hole of the self-locking nut, and the surface of revolution is a cylindrical surface, a spherical surface or a hyperboloid. The polygonal edges are regular hexagons or regular quadrilaterals. The polygonal edges are regular hexagons. The material of the self-locking nut is spring steel or tool steel. The spring steel is 65Mn.

[0013] The regular hexagonal nut edge can unify the tools during installation, reduce the number of tools, reduce production costs and improve production efficiency. The upper and lower ends of the nut are symmetrical concave cylindrical surfaces to facilitate processing, uniform deformation, and reduce the stress concentration of the self-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com