Backlight module and assembly method thereof

A technology of a backlight module and an assembling method, which is applied to electric light sources, lighting devices, fixed lighting devices, etc., can solve the problems of breakage or damage, the difficulty of designing and manufacturing the plastic frame 16, and the decline of the assembly yield of the backlight module 1, etc. The effect of thinning and preventing light leakage from the side

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0027] The purpose of the present invention is to provide a backlight module and an assembly method thereof which can prevent or reduce light leakage from the side of the light guide plate, and at the same time facilitate thinner design.

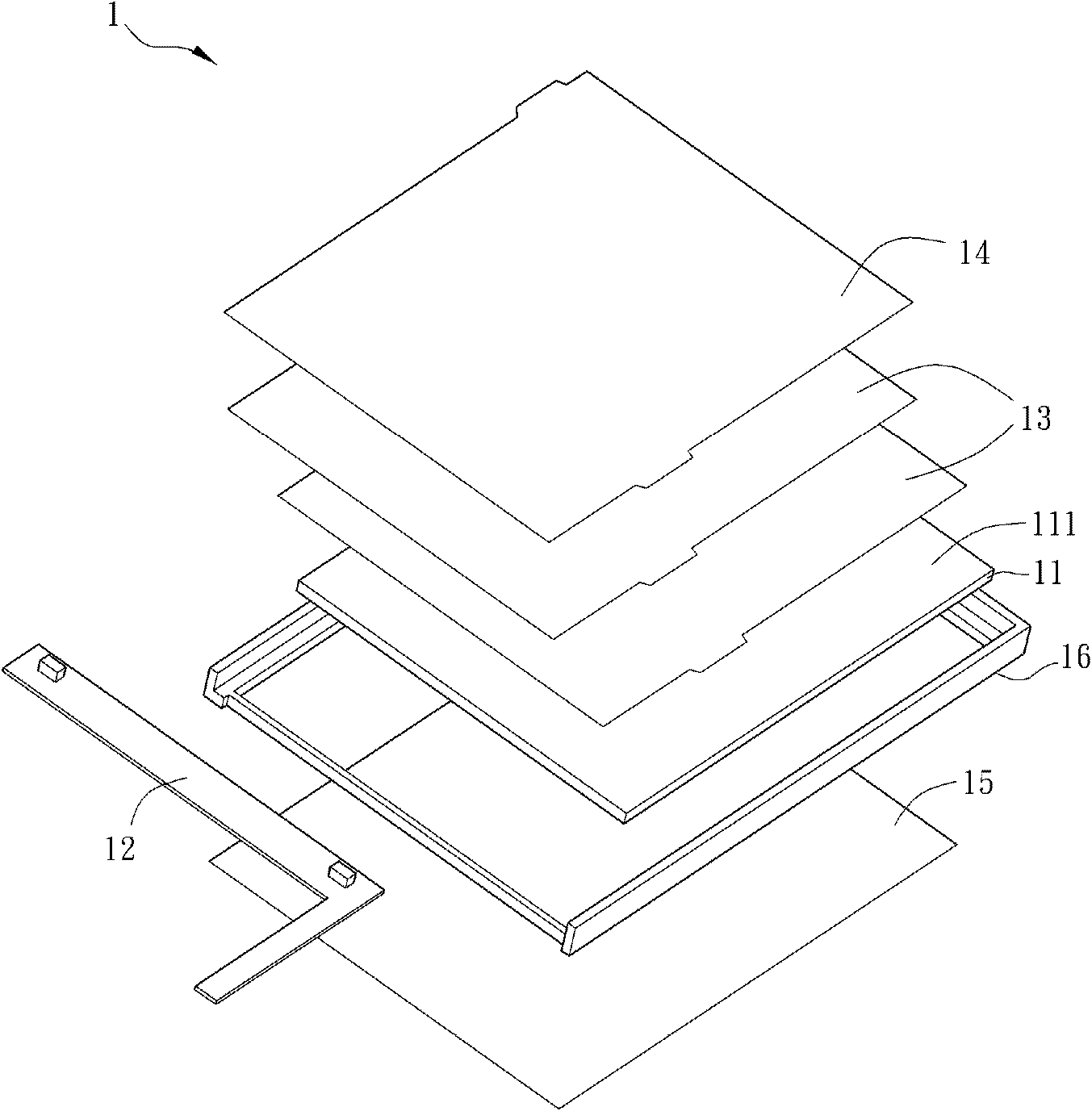

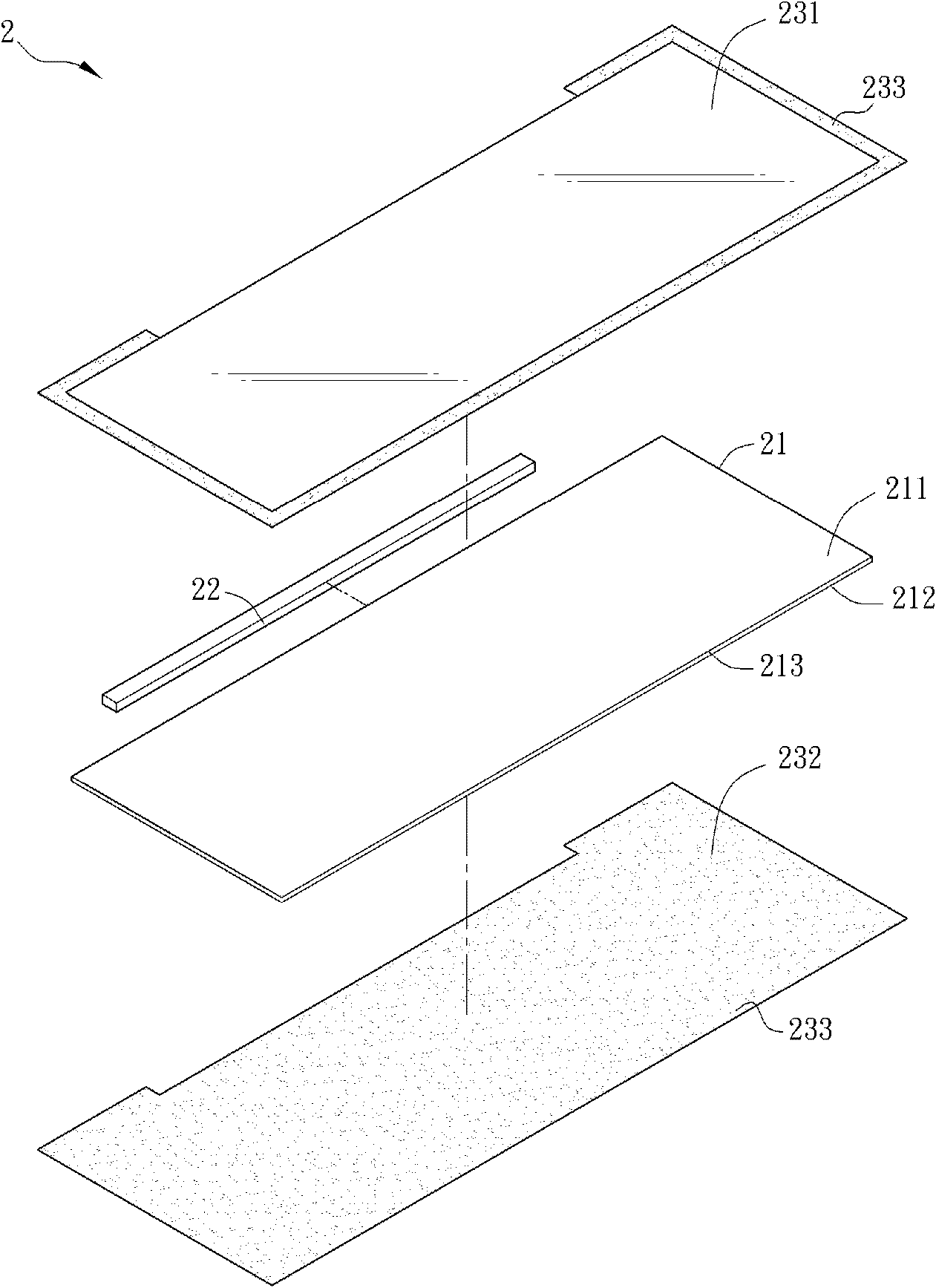

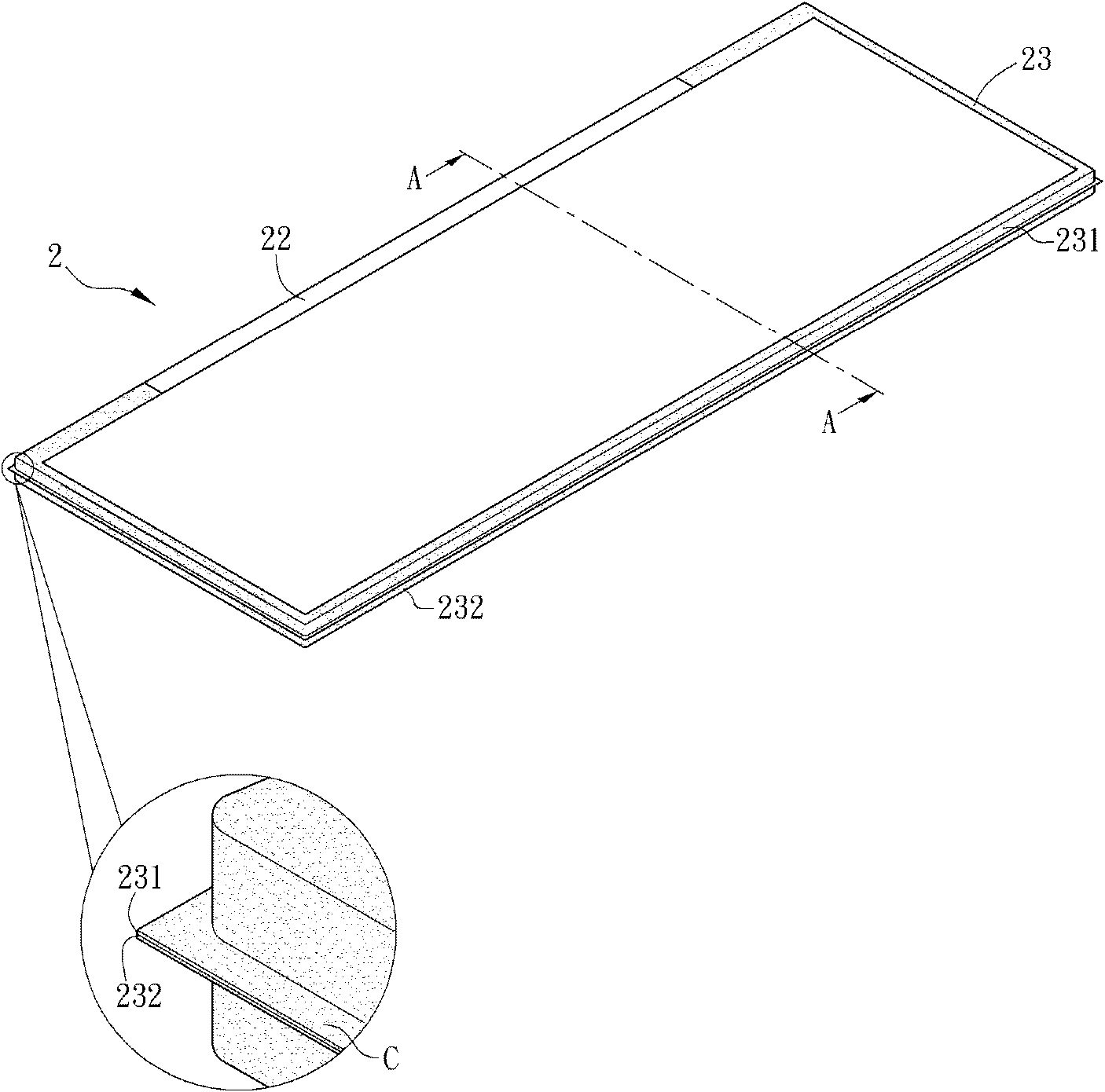

[0028] To achieve the above purpose, a backlight module according to the present invention includes a light guide plate, a light emitting unit and a film material unit. The light guide plate has a light-emitting surface, a bottom opposite to the light-emitting surface and a side surface, and the side is connected to at least one of the light-emitting surface and the bottom surface. The light emitted by the light emitting unit enters the light guide plate. The size of the film unit is larger than the size of the light guide plate, the light guide plate is accommodated in the film unit, the film unit has at lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com