Multi-fire head continuous balanced combustion method and long-tube rotary stove derived therefrom

A rotary furnace and long tube technology, which is applied to furnaces/stoves with hot water devices, household appliances, steam boilers, etc., can solve the problems of less coal gasification, large changes in furnace temperature, and weak firepower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

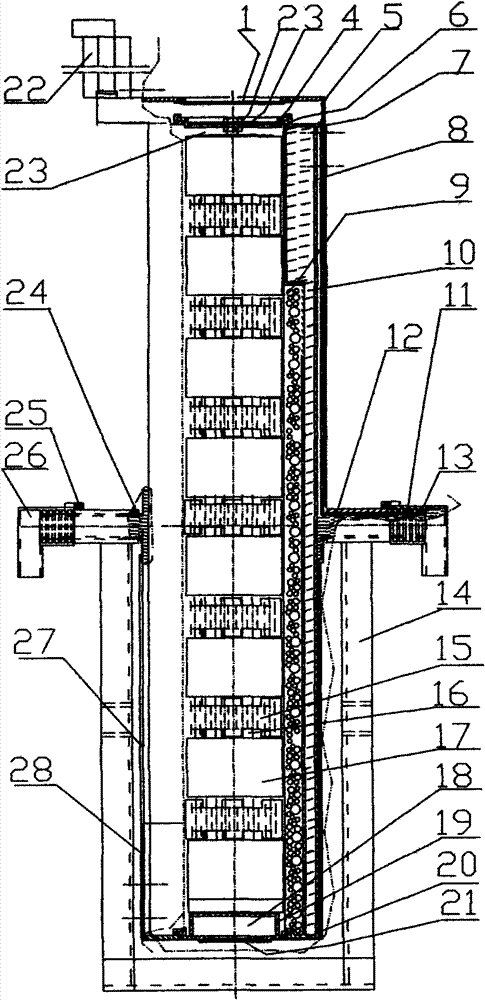

[0171] Such as figure 1 As shown: the rectangular water tank 22 of the long-tube rotary stove is integrated with the rectangular chimney that it wraps, and the short rectangular joint of the chimney of the rectangular water tank 22 is inserted in the end face smoke exhaust port of the stove 5; The upper fire cover 1 is installed inside. In order to reduce the leakage of smoke, the bottom plane of the upper fire cover 1 is a little lower than the lower end surface of the furnace plate 5; the furnace plate 5 is fixed on the furnace body 8 with three positioning bolts 7; The upper end of the furnace mouth of the furnace body 8 is the upper cylinder tile ring 6, and there is an annular groove in the inner diameter of the upper cylinder tile ring 6, the upper end surface of the annular groove, three convex gaps equally distributed, and three bosses of the middle fire cover 4 Just pass through the gaps of these three bosses, enter the annular groove of the upper cylinder tile ring 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com