Bare wire electric water heater

A technology for electric water heaters and heaters, applied in fluid heaters, lighting and heating equipment, etc., can solve problems such as difficult installation and complex structure, and achieve the effects of improved heat exchange efficiency, compact structure, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

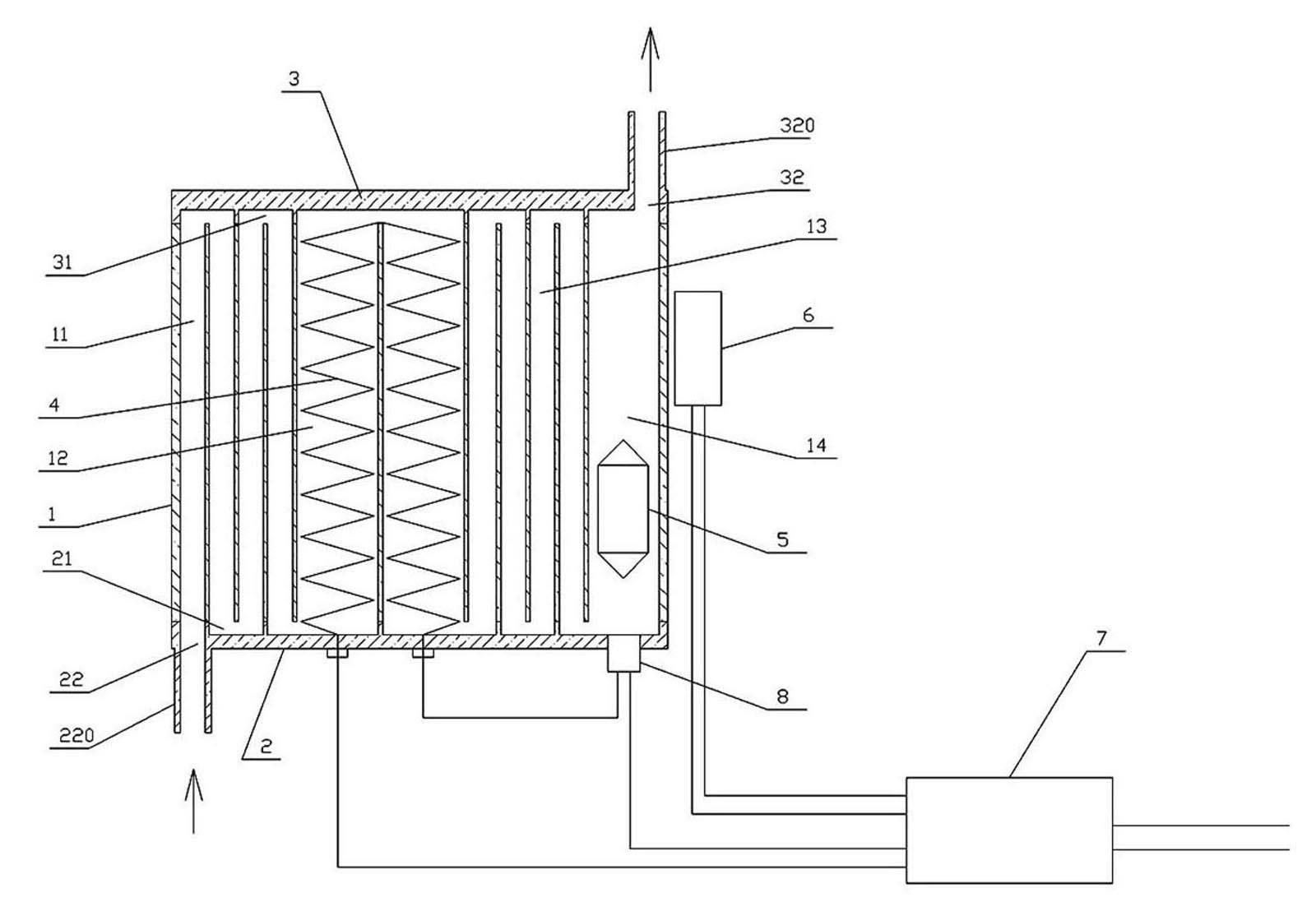

Embodiment 1

[0024] refer to figure 1 with Figure 9 , a bare wire electric water heater heater, including a heating body, an electric heating wire 4 and a power supply controller 7, the heating body includes a main body 1, an upper cover 3 and a lower cover 2, the lower cover 2 is provided with several lower connecting grooves 21, and the upper cover 3 A plurality of upper connecting grooves 31 are provided, the lower cover 2 is provided with a water inlet 22 and is connected to a water inlet joint 220, the upper cover 3 is provided with a water outlet 32 and is connected to a water outlet joint 320, and the main body 1 is provided with a number of parallel water channels. The upper cover 3 and the lower cover 2 connect the water passages in the main body 1 in series through the upper connecting groove 31 and the lower connecting groove 21 respectively to form a water inlet and electricity protection wall 11, an electric heating chamber 12 and an outlet water and electricity protection ...

Embodiment 2

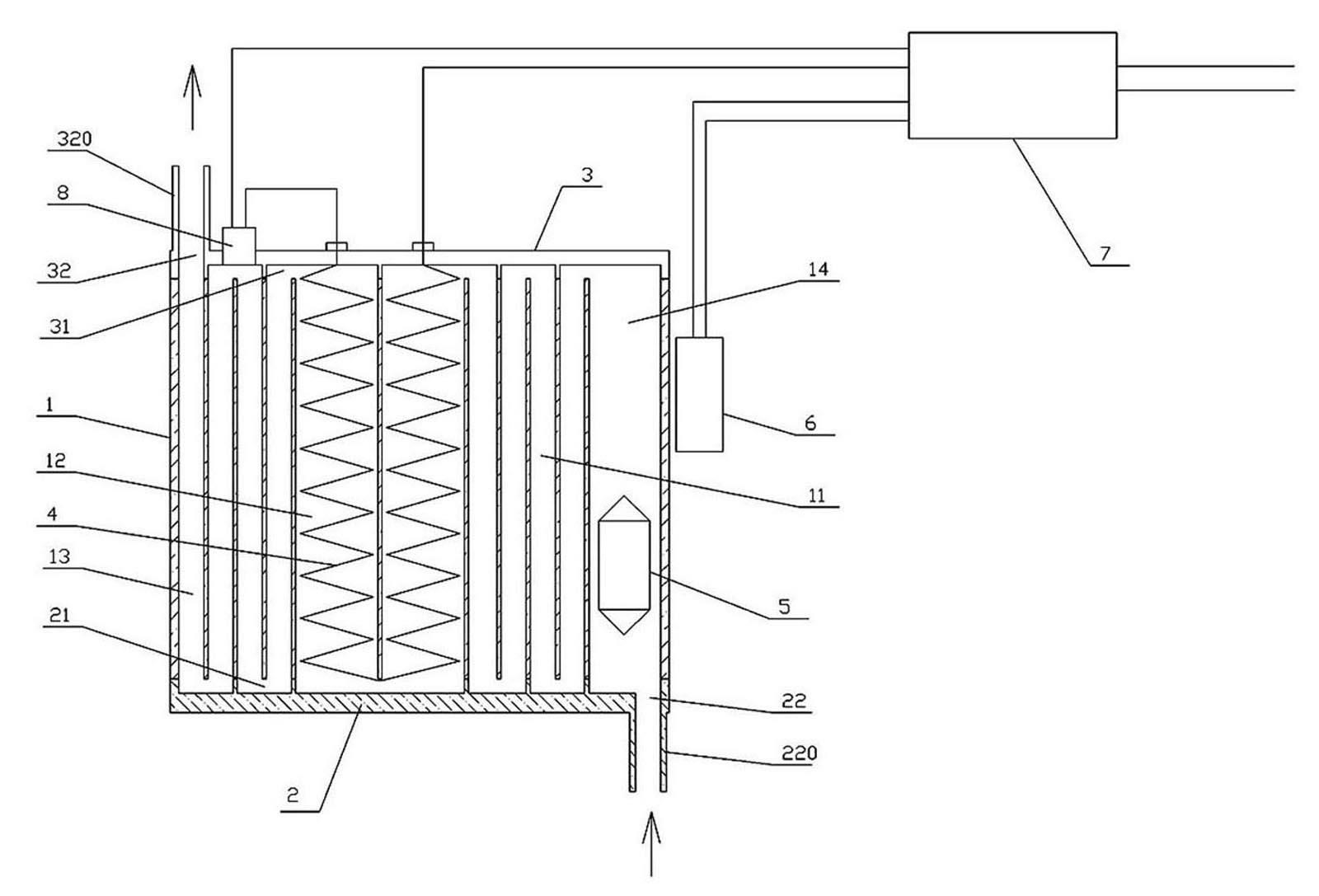

[0039] refer to figure 2 , the difference between this embodiment and Embodiment 1 is that the water flow switch channel 14 is set on the water inlet and electricity protection wall 11, that is, one of the water channels of the water inlet and electricity protection wall 11 is used as the water flow switch channel 14, and the water flow switch channel 14 has a built-in magnetic levitation Sub 5, the outer side of the main body 1 near the water flow switch channel 14 is provided with a magnetic contact switch 6, and the water outlet electric wall 13 has no water flow switch channel.

[0040] Its working principle is the same as that of Embodiment 1.

[0041] The heating body of this embodiment can also adopt such as Figure 9 structure, will Figure 9 Water inlet 22 and water outlet 32 in the interchange just passable, be about to make water inlet 22 water inlet, water outlet 32 is made water inlet.

Embodiment 3

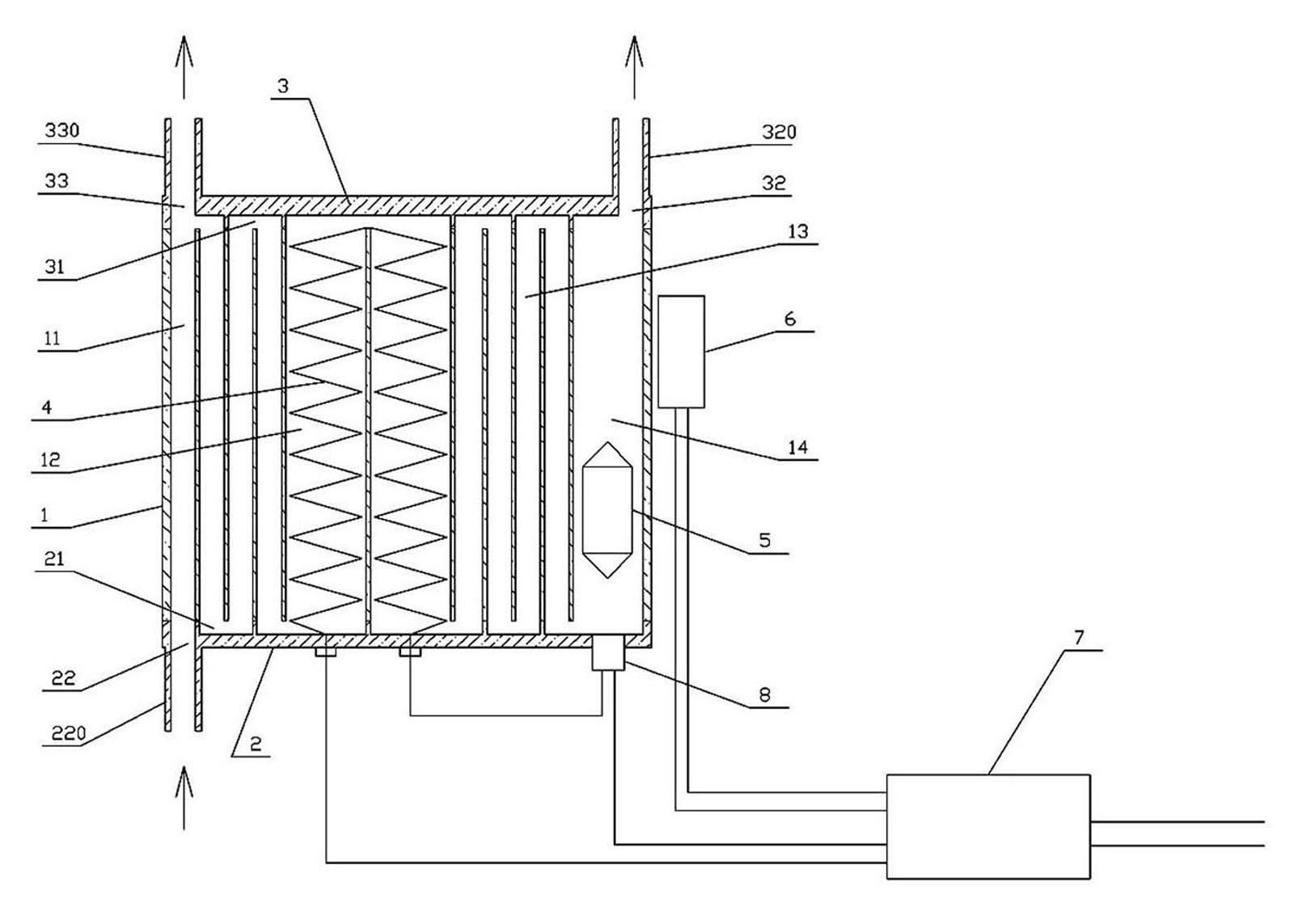

[0043] refer to image 3 , the difference between this embodiment and embodiment one is:

[0044] The upper cover 3 is also provided with a middle water outlet hole 33 connected to the middle water outlet joint 330 , and the middle water outlet hole 33 communicates with one of the water passages of the water inlet and electric protection wall 11 . This further enables the output of hot or cold water at different temperatures:

[0045] During installation, use the water inlet pipe to connect the water inlet joint 220 to the tap water source, connect the plug of the power supply controller 7 to the power supply, and connect the water outlet joint 320 and the middle water outlet joint 330 to the 2-in and 1-out mixing water regulating valve (Fig. 2 water inlets (not shown), and the water outlet of the mixing regulating valve is connected to the water outlet pipe.

[0046] The working principle is:

[0047] When cold water is to be used, the mixed water regulating valve is adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com