Heat exchanger fin stock lubrication system

A lubricating system and raw material technology, applied in the field of heat exchanger fin raw material lubricating system, can solve problems such as unreliability and no application process control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

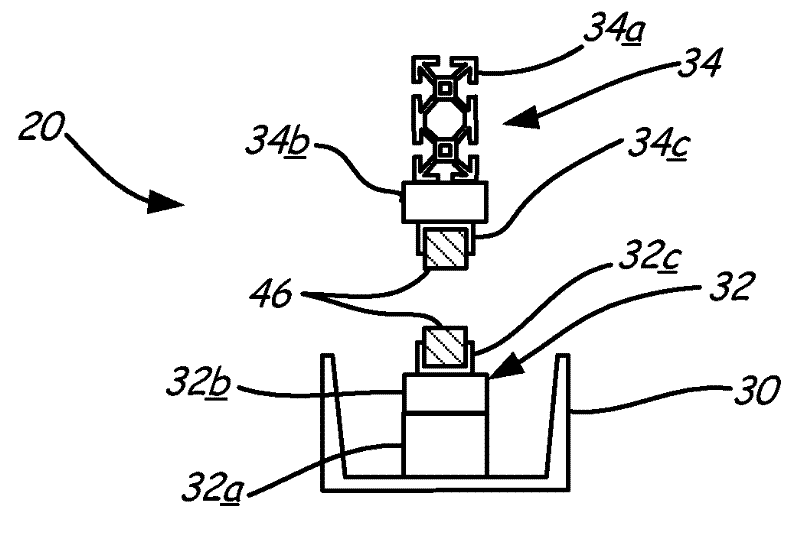

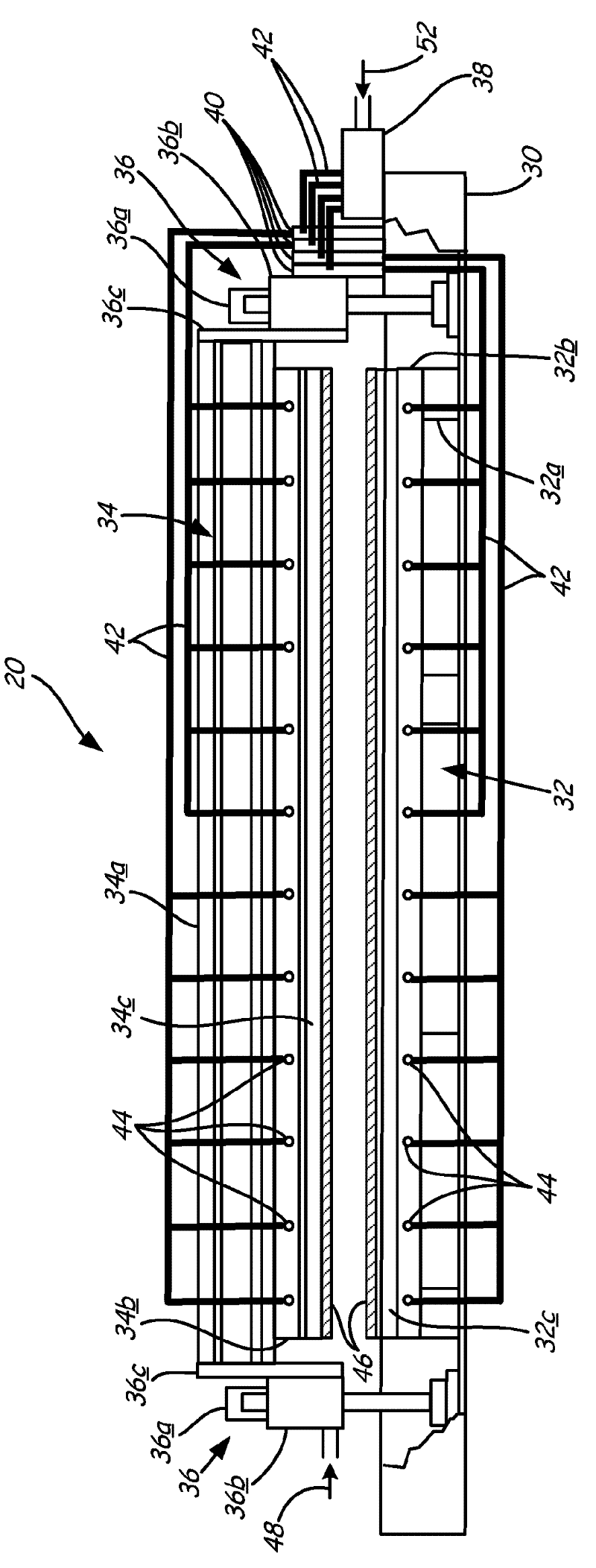

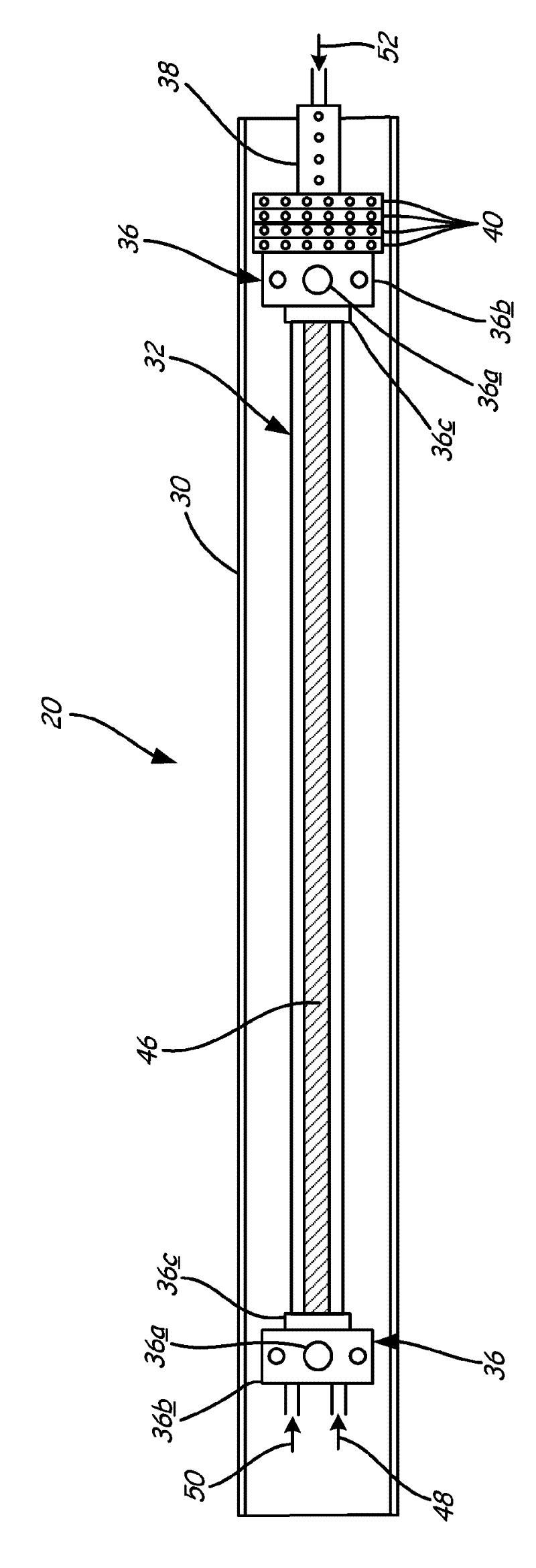

[0012] figure 1 is a schematic diagram of a system 10 for manufacturing heat exchangers from sheet metal stock, the system 10 including a die press 12 , an uncoiler 14 , a lubrication system 16 and a sheet metal stock 18 . exist figure 1 Among them, the die press 12 is configured to receive sheet metal stock 18 and form it into, for example, corrugated sheets 19 from which heat exchanger fins may be constructed. The uncoiler 14 is configured to supply sheet metal stock 18 to the die press 12 . In some embodiments, the uncoiler 14 is a passive device and the printer 12 is configured to pull the sheet metal stock 18 from the uncoiler 14 . The sheet metal raw material 18 may be, for example, a thin sheet of aluminum from which heat exchanger fins are generally constructed. Without proper lubrication during the stamping process, the sheet metal stock 18 may gall and crack as it is formed into the profile of the die in the die punch 12 . Embodiments of the invention thus includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com