Hair straightener

A hair and main handle technology, applied in hairdressing equipment, curling or perming devices, clothing, etc., can solve the problems of water tank drop, easy loosening, circuit board short circuit, etc., to achieve easy opening and closing, not easy to fall off, installation and The effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to have a further understanding of the structure and achieved effects of the present invention, the detailed description is as follows in conjunction with the accompanying drawings and preferred embodiments.

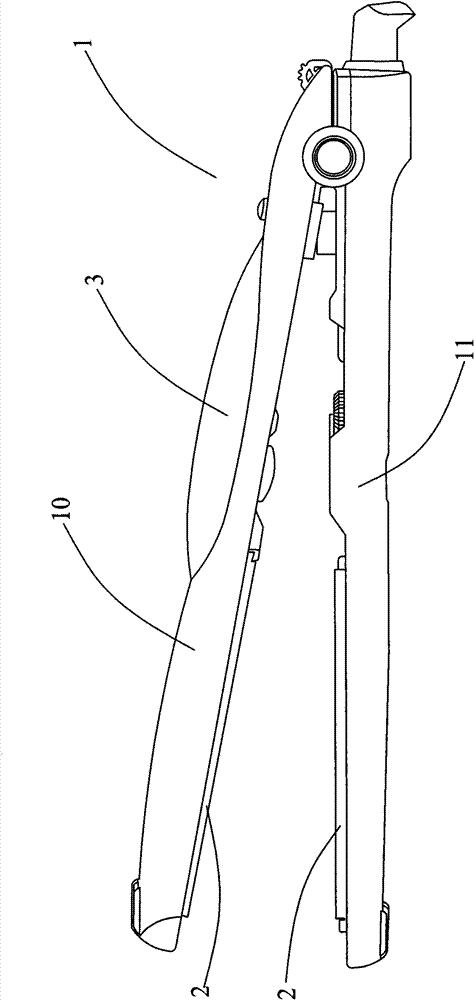

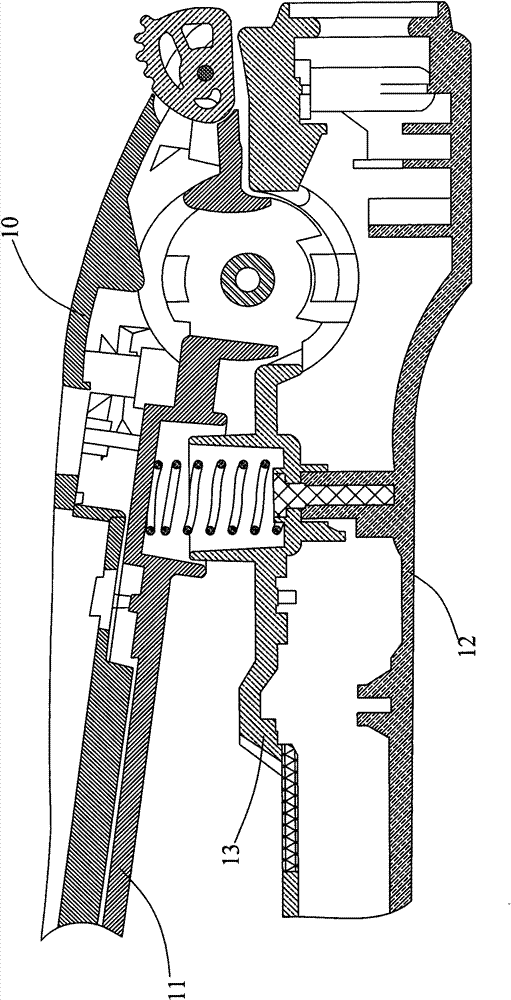

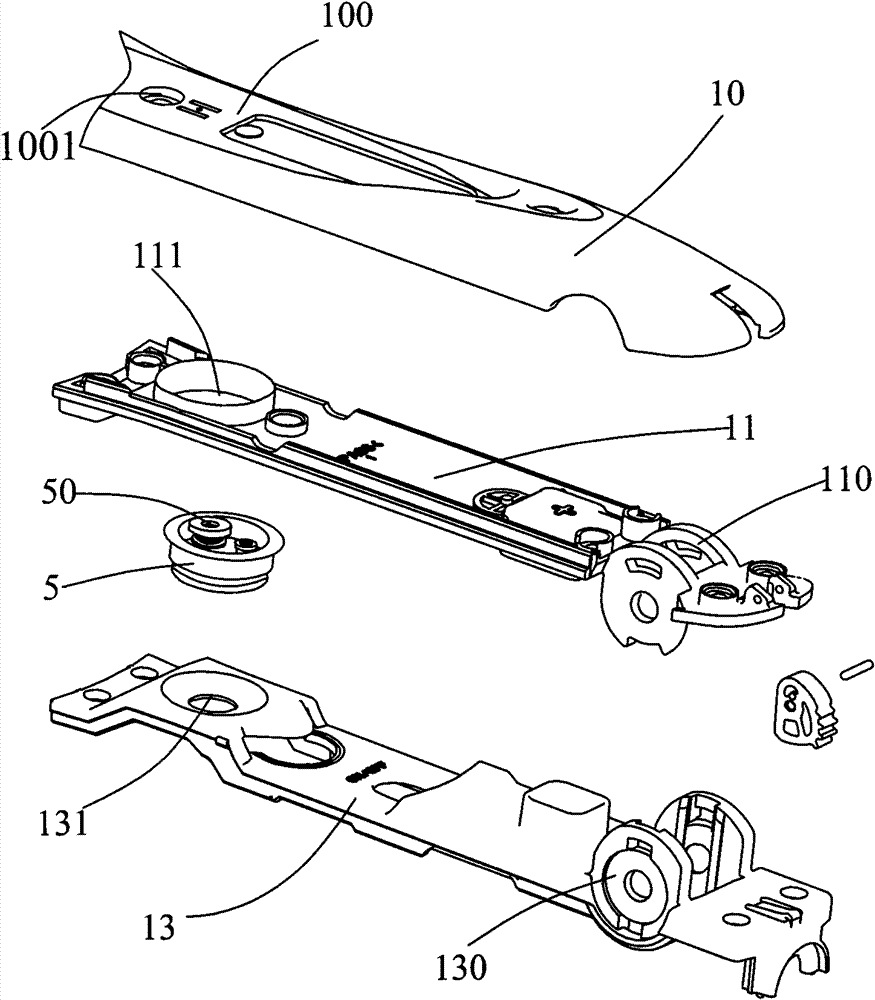

[0031] Such as figure 1 and figure 2 As shown, the hair straightener of the present invention includes a handle 1, a clamping part 2, a water tank 3 and a power circuit (not shown in the figure), the handle 1 is divided into an upper main handle 10, a last handle 11, a lower main handle For the handle 12 and the next handle 13, there are two clamping parts 2 in the present invention, and they are arranged oppositely. The two clamping parts 2 are embedded and fixed on the front ends of the upper main handle 10 and the lower main handle 12. 11 is embedded and fixed on the end of the upper main handle 10 away from the clamping part 2, the next handle 13 is embedded and fixed on the end of the lower main handle 12 away from the clamping part 2, and the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com