Method for manufacturing raw tyre for automatic bicycle

A technology of an automatic two-wheeled vehicle and a manufacturing method, which is applied in the directions of tires, applications, household appliances, etc., can solve problems such as difficulty in transportation, storage and handling, and achieve the effect of suppressing process loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

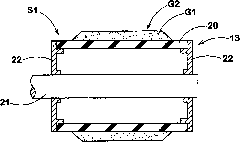

[0081] Based on the manufacturing method of the present invention, with the specifications in Table 1, the tire specifications of 190 / 50Z R17 and 160 / 60ZR17 were trial-produced for motorcycle tires for motorcycles. Ripple (snake pattern) and the incidence of defective products were compared.

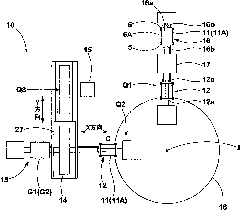

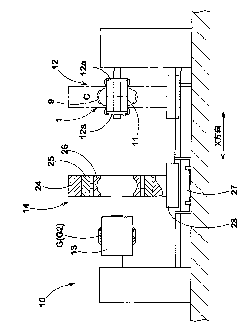

[0082] Each tire differs only in the method of forming the tread cylinder, as described in Figure 9As shown in (A), in Conventional Examples A1 and B1, the two sides of the tread cylinder formed in a cylindrical shape are gathered and bonded to the raw tire body by a pressing device. In addition, in the tire of the tire standard (190 / 50Z R17), the carcass and the belt layer have the following specifications.

[0083] ·Carcass

[0084] Number of curtains: 1 piece

[0085] Carcass cord: Nylon: 1400dtex / 2

[0086] Number of cords inserted: 35 / 5cm

[0087] Cord angle: 90° (angle relative to the circumferential direction)

[0088] ·Belt

[0089] Number of curtains: 1 piece

[0090] Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com