Linkage clutch of washing machine

A clutch device, washing machine technology, applied in washing devices, other washing machines, textiles and papermaking, etc., can solve the problems of low transmission intensity, high manufacturing cost, complex structure, etc., and achieve accurate control, high transmission intensity, and small size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

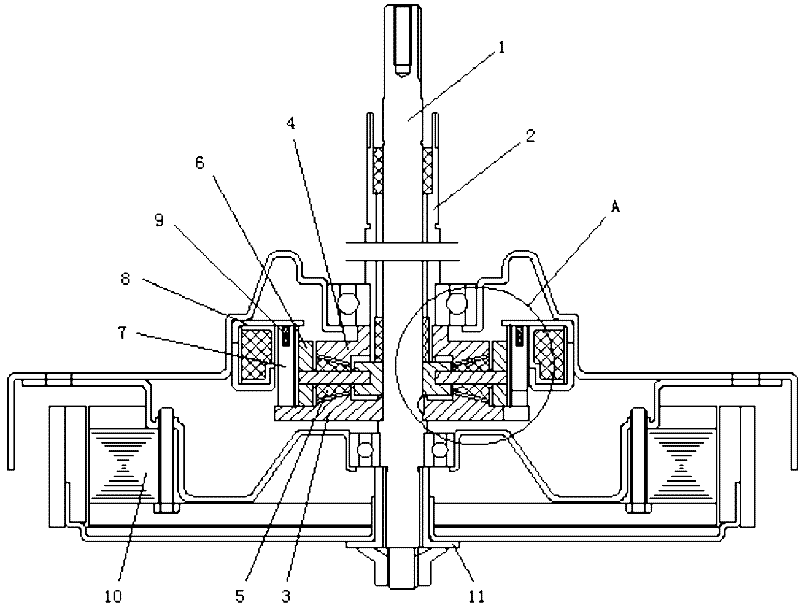

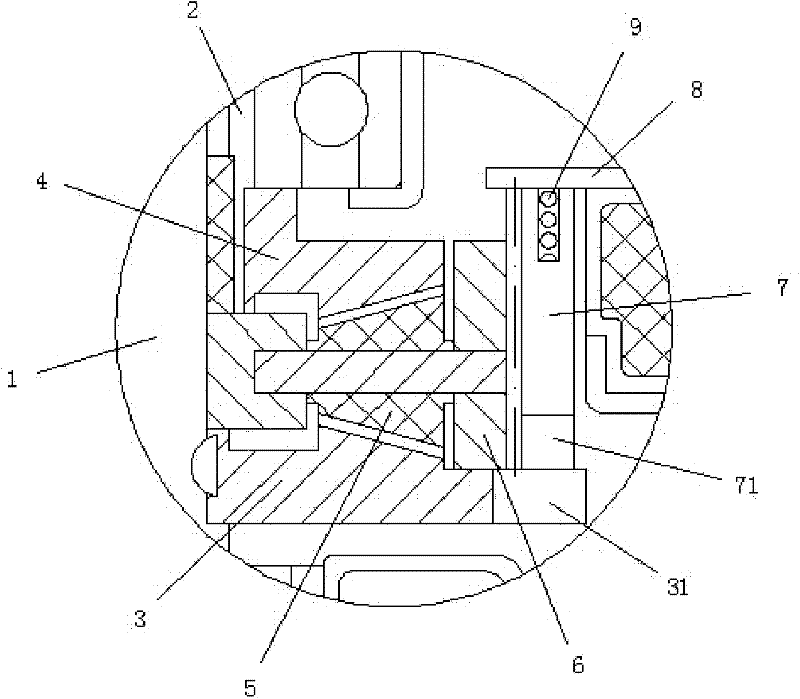

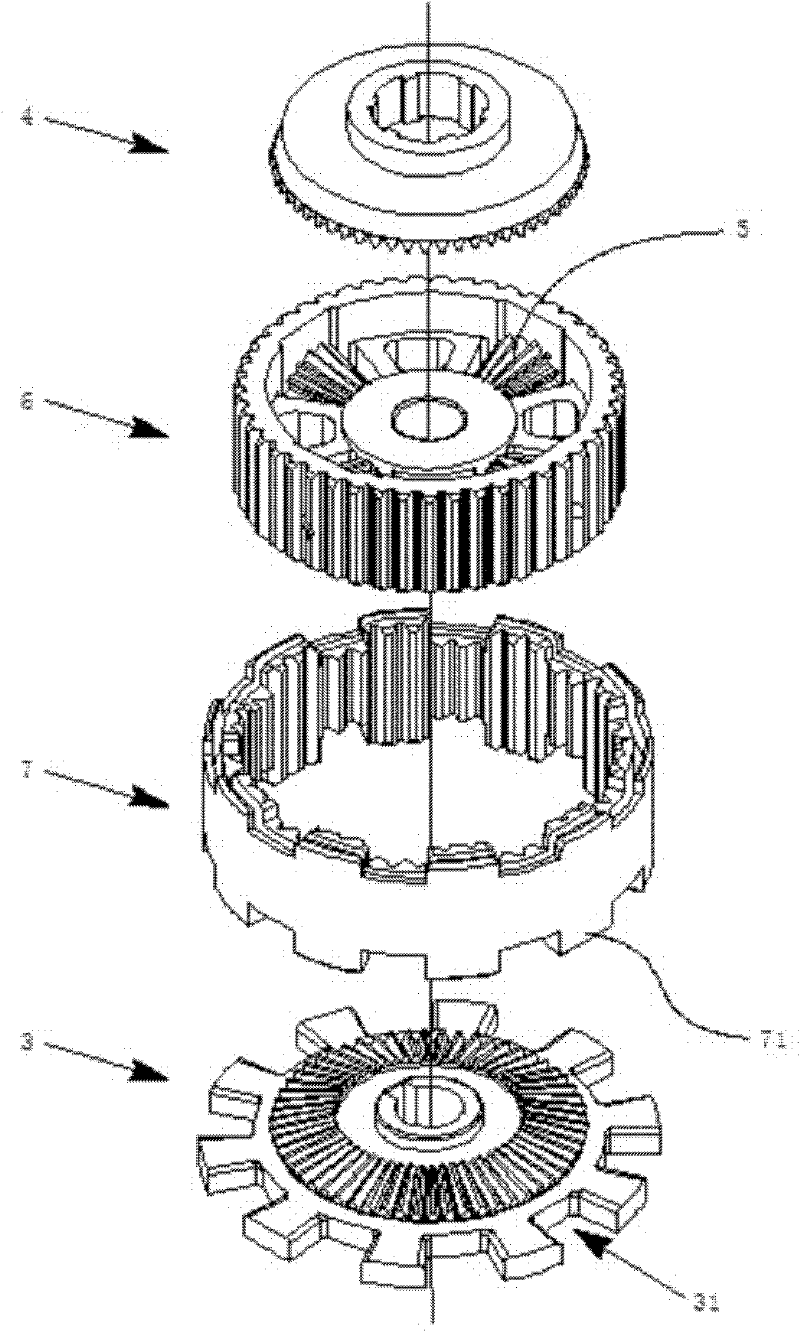

[0015] See figure 1 and figure 2 , the present invention has a drive shaft 1 and a drive shaft sleeve 2, the drive shaft 1 is rotatably arranged in the drive shaft sleeve 2, the drive shaft 1 is fixedly connected to the drive toothed disc 3, the drive shaft sleeve 2 is fixedly connected to the driven tooth disc 4, and the driving Between the gear plate 3 and the driven gear plate 4, there is a planetary gear 5 that meshes with the above two gear plates at the same time. The planetary gear 5 is 4 bevel gears, which are arranged on the planetary gear cage 6 with external teeth through the rotation of the gear shaft. , the driving gear 3 and the driven gear 4 are also bevel gears matching the planetary gear 5 ; It can slide up and down, ten slots 71 are evenly distributed on the lower end of the clutch ring gear 7, ten slots 31 matching the slot teeth 71 are evenly distributed on the outer end of the drive tooth disc 3, and an electromagnetic coil 8 is arranged above the clutch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com