Roller for inhibiting vibration and method thereof

A technology of rollers and roller sleeves, applied in the directions of shafts and bearings, textiles and papermaking, papermaking machines, etc., can solve the problems of expensive application, inability to adjust the deflection in a targeted manner, large structure and manufacturing technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

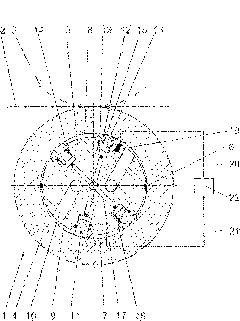

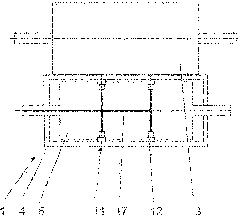

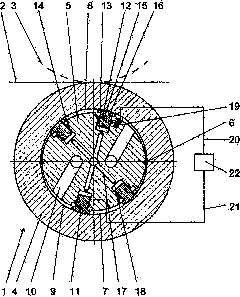

[0033] exist figure 1 , a section of the roller 1 according to the invention can be seen. The rollers work together with a pair of rollers 3, shown in dashed lines, in order to process the fibrous web 2, also shown in dashed lines, in the so-called nip between them.

[0034]The roller 1 has a rotating sleeve 4 and a stationary shaft 5 . A longitudinal seal 6 is arranged between the sleeve and the shaft, which longitudinal seal 6 divides the annular chamber 7 into an upper chamber 8 and a lower chamber 9 . The two chambers are filled with pressurized fluid, typically oil, at different pressures. The channel 10 is designed as a channel for the chambers 8 , 9 to input or output pressure fluid. The different pressures in the chambers 8 and 9 enable the roll 1 to bend in accordance with the counterpart roll 3 . For various reasons, eg an uneven fiber web to be treated or an out-of-round roll, the system consisting of roll 1 and counter roll 3 is prone to vibrations. Such vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com