Topdown construction method of basement exterior wall

A basement exterior wall and construction method technology, applied to artificial islands, water conservancy projects, underwater structures, etc., can solve problems such as easy water seepage, side wall shrinkage is difficult to control, etc., to ensure quality, increase the overall strength of the exterior wall, and facilitate Processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

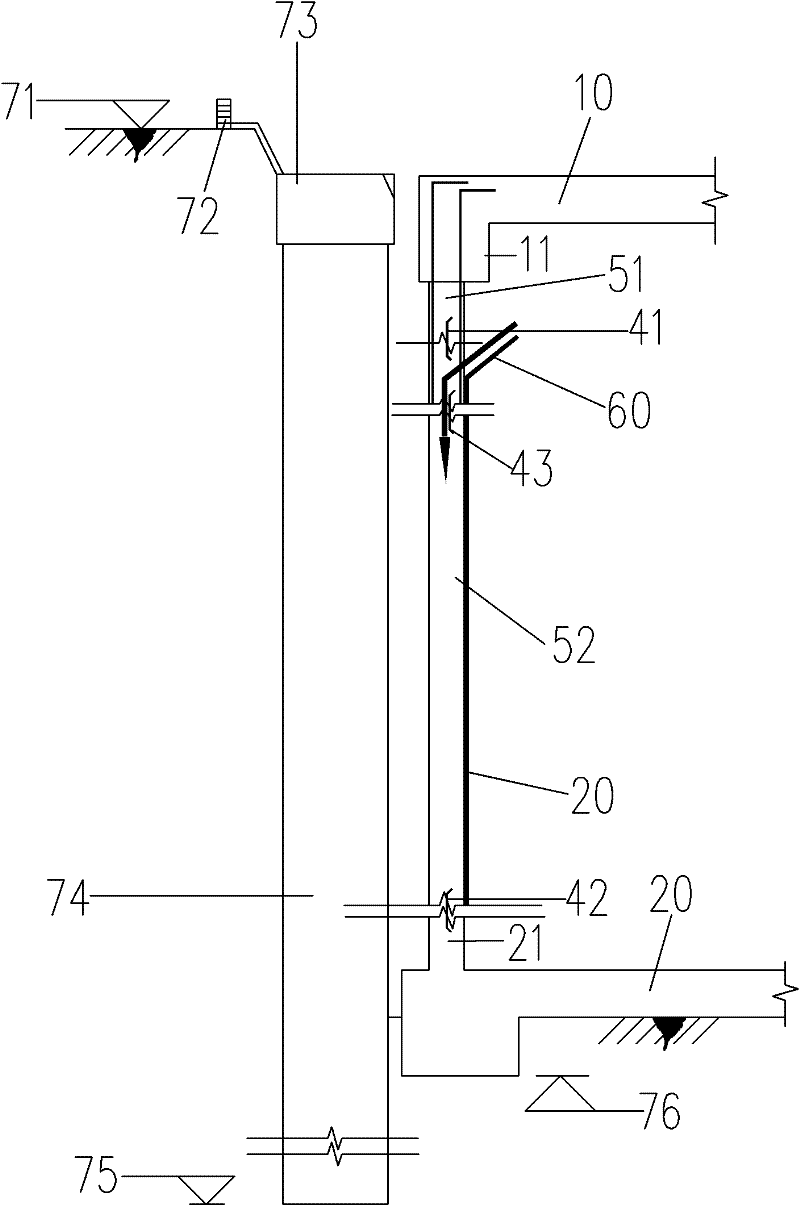

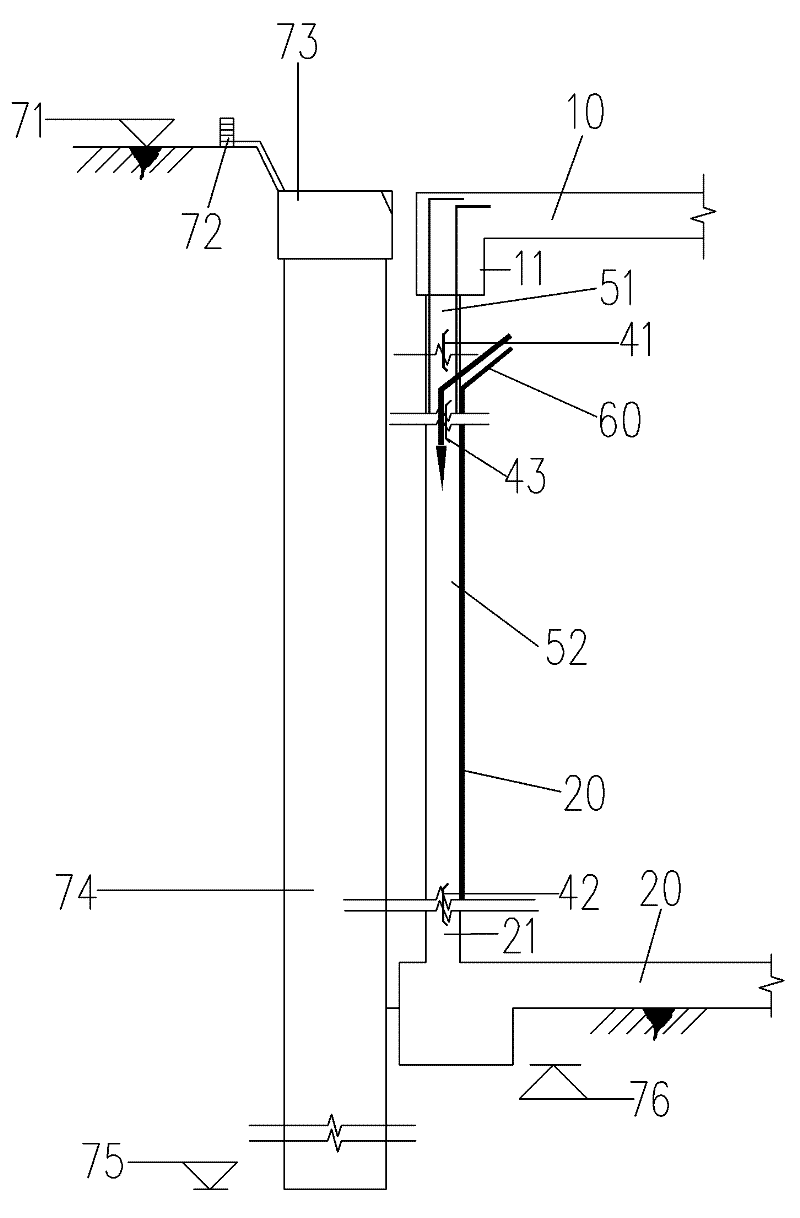

[0043] Please check figure 1 , a method of reverse basement exterior wall construction, which comprises:

[0044] Step 1, for the construction of the top and bottom plates, the top plate 10 has a downwardly facing upper boss 11, and the bottom plate 20 has an upwardly facing lower boss 21;

[0045] Step 2, for installing the wooden formwork 30 for the side wall, the wooden formwork 30 surrounds the outer cylindrical surface of the upper boss 11 and the outer cylindrical surface of the lower boss 21;

[0046] Step 3, for installing the first water stop plate 41 on the wooden formwork 30, pouring concrete in the section between the upper boss 11 and the first water stop plate 41 in the wooden formwork 30, and forming the upper section of concrete 51, The upper concrete 51 is connected with the upper boss 11;

[0047] Step 4, for installing the corbel 60 on the wooden formwork 30, the port of the corbel 60 is higher than the first water stop plate 41, and the second water stop ...

Embodiment 2

[0054] The difference between this embodiment and the previous preferred embodiment is that the step 5 includes:

[0055] Step 51, for pouring concrete to the part above the second water stop plate in the wooden mold, and forming the first lower section of concrete, and the first lower section of concrete and the lower bump are connected as one;

[0056] Step 52, for using the corbel to pour concrete into the section between the first lower section concrete and the upper section concrete in the wooden form, and forming the second lower section concrete, the second lower section concrete, the first lower section concrete and the upper section Concrete molding.

Embodiment 3

[0058] The differences between this embodiment and the previous preferred embodiment are:

[0059] A construction method for a basement exterior wall by the reverse method, comprising:

[0060] Step 1, for constructing the top and bottom plates, the top plate has a downwardly facing upper boss, and the bottom plate has an upwardly facing lower boss;

[0061] Step 2, for installing the side wall wooden formwork, the wooden formwork is surrounded by the outer cylinder surface of the upper boss and the outer cylinder surface of the lower boss;

[0062] Step 3, for installing the corbel on the wooden formwork, and installing the second water stop plate on the lower boss;

[0063] Step 4, for installing the first water stop plate on the wooden formwork, the first water stop plate is lower than the port of the corbel, and the part between the upper boss in the wooden formwork and the first water stop plate is poured with concrete , and formed into the upper section of concrete, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com