Container type house

A container-type, housing technology, applied in the direction of construction, building construction, etc., can solve the problems of limited housing space, small space utilization rate, weak plasticity, etc., to reduce the assembly workload, and the procedure of opening and closing is simple , enhance the effect of plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

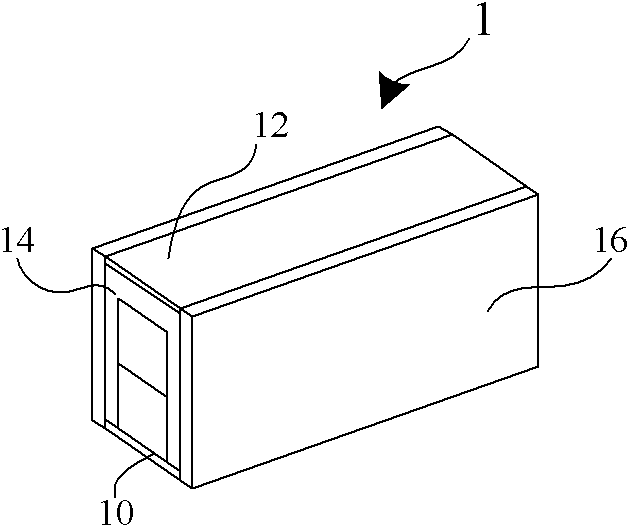

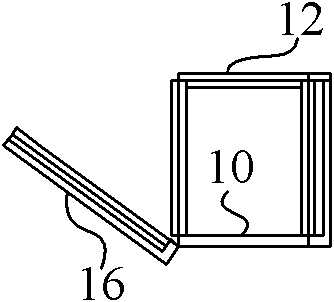

[0037] Figure 1a to Figure 1c , Figure 2a to Figure 2c , Figures 3a to 3c and Figure 4a to Figure 4c It is a structural schematic diagram of the container house in the first embodiment of the present invention. The container-type house of the present invention includes a container-type box shell 1 (which can also be transformed from waste containers according to a specific method) and a liner (not shown in the drawings) located in the box shell 1 .

[0038] The container-type box shell 1 includes a box bottom 10 , a box cover 12 , two end box surfaces 14 and two side box surfaces 16 located between the box bottom 10 and the box cover 12 .

[0039] In the first embodiment, the container house of the present invention is a one-side unfolded structure.

[0040] Figures 1a to 1c and Figures 2a to 2c It shows the first type of one-side expandable container house in the first embodiment, Figures 3a to 3c and Figures 4a to 4c It shows the second type of one-side expand...

no. 1 example

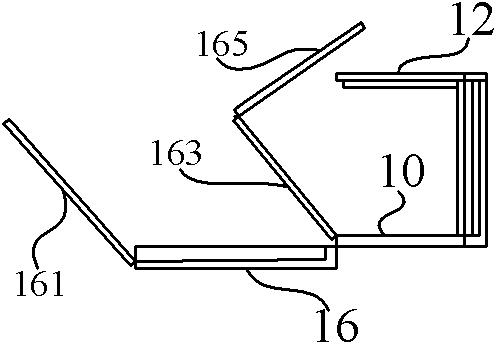

[0049] The first embodiment (single-layer slope-roof house with one-side expansion of single box)

[0050] Figures 6a to 6e , which is a structural schematic diagram of a container house in the first embodiment used to build a single-box single-side-expandable single-story slope roof house. like Figures 6a to 6e As shown, at first, one of the side case surfaces 16 of the container-type box shell 1 is opened upwards, and at the same time, the inner liner panel 161 hinged with the side case surface 16 is opened, and the expanded inner liner panel 161 and the side case surface 16 is used as the roof of the house; and then the inner tank boards 163, 165, 167 hinged with the bottom of the box 10 are opened successively, wherein the inner tank boards 163, 165 are opened to a horizontal position substantially equivalent to the bottom of the box 10, as the ground of the house, The inner tank board 167 is unfolded and placed vertically to support the inner tank board 161 as a suppo...

no. 2 example

[0054] The second embodiment (two boxes of single-side unfolded laminated combination):

[0055] Figure 7a to Figure 7d It shows a structural schematic view of the present invention using the container house in the first embodiment to form a stacked combination of two boxes with one side unfolded. Firstly, the first type of single-side expandable container house and the second type of single-side expandable container house are respectively provided; Figure 7a , the side case surface 16 and the inner tank boards 161, 163, 165 on one side of the first type of box shell 1 are lifted successively; as Figure 7b , the side case surface 16 and the inner tank panels 161, 163, 165 on one side of the box shell 1 in the second type are lifted successively; as Figure 7c , the first type of box shell 1 is stacked on the second type of box shell 1; subsequently, using the accessory structure of the box (such as beams, system walls, hanging box devices, supporting steel columns, etc....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com