Water vapor rotating jet dust settling device for comprehensive driving working face

A technology of dust suppression device and working face, which is applied in the direction of safety devices, dust prevention, mining equipment, etc. It can solve the problems of poor atomization effect, low water pressure in front of the nozzle, and jet flow cannot be atomized, etc., and achieves easy nozzle clogging and device structure. Simple, easy-to-use effects

Active Publication Date: 2011-09-21

HUAIBEI MINING IND +2

View PDF8 Cites 42 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

It should be said that the above-mentioned studies have played a certain role in reducing the dust generated by the roadheader. However, due to various reasons, the above-mentioned technologies have not been widely used.

In actual use, there are still some problems with the internal and external spraying: one is that the nozzles arranged on the drum are partially or completely buried in the coal when the drum is cut, so that the sprayed jet cannot be atomiz

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Total length | aaaaa | aaaaa |

Login to View More

Abstract

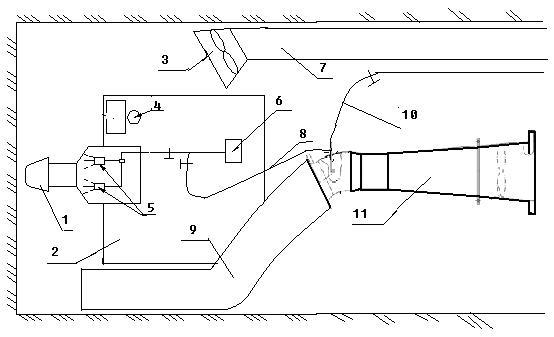

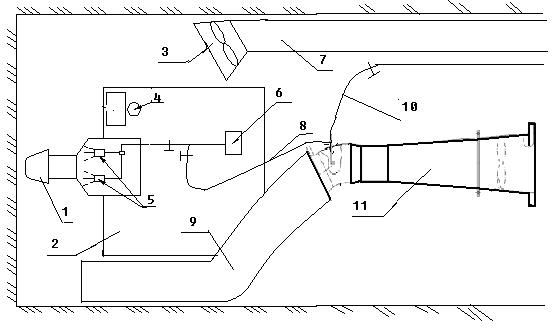

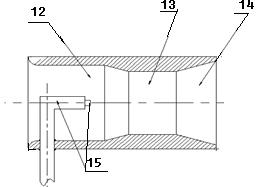

The invention discloses a water vapor rotating jet dust settling device for a comprehensive driving working face, and belongs to the technical field of comprehensive driving working face dust settling and removing equipment. The dust of the comprehensive driving working face is reduced by combined action of a rotating jet air suction type spray device, a secondary rotating compressed air water jet dust absorption and removal device and a rotational flow air supply dust control device; and the rotating jet air suction type spray device sprays water to a roller cutting point and a shipping point. The pressure water of a water pipe becomes fog of finer fog drops and is sprayed to a dust production area so as to reduce the dust produced by a development machine during cutting coal, suck the nearby air and form a cyclone water vapor curtain mask; and the secondary rotating compressed air water jet dust absorption and removal device and a negative pressure air cylinder remove the dust whichis sucked into the rotating jet air suction type spray device by means of compressed air and spray of high pressure water in a venturi tube and is not caught, and the distance between the negative pressure air cylinder and a driving head is 2 to 5 meters.

Description

A water-air rotating jet dust suppression device for fully mechanized excavation working face technical field The invention belongs to the technical field of dust reduction and dust removal equipment for fully mechanized excavation working faces. Background technique The fully mechanized excavation face is one of the sources of high dust in coal mines. Effectively reducing the dust concentration of coal cut by roadheaders is of great significance to the safety of coal mine production and the health of workers. In order to reduce the dust concentration of fully mechanized excavation work and effectively prevent the dust generated by the coal cutting of the roadheader, the dust prevention measures for the machine face at home and abroad mainly include spraying inside and outside the roadheader, using dust collectors, and adopting pull-out or push-in-pull combined ventilation. Methods, personal protection, etc. In recent years, related research has been carried out on the fo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E21C35/22E21F5/04E21F5/20E21F1/00E21F1/04

Inventor 陈家祥马中飞沐俊卫梁峰徐瑞杨秀莉李洪彬刘军

Owner HUAIBEI MINING IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com