Touch panel test equipment and detecting device thereof

A technology for testing equipment and touch panels, which is applied to test equipment for detecting tiny capacitive signals on touch panels, and in the field of equipment for testing touch panels, and can solve problems such as the inability to obtain capacitance values in circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be described in detail below.

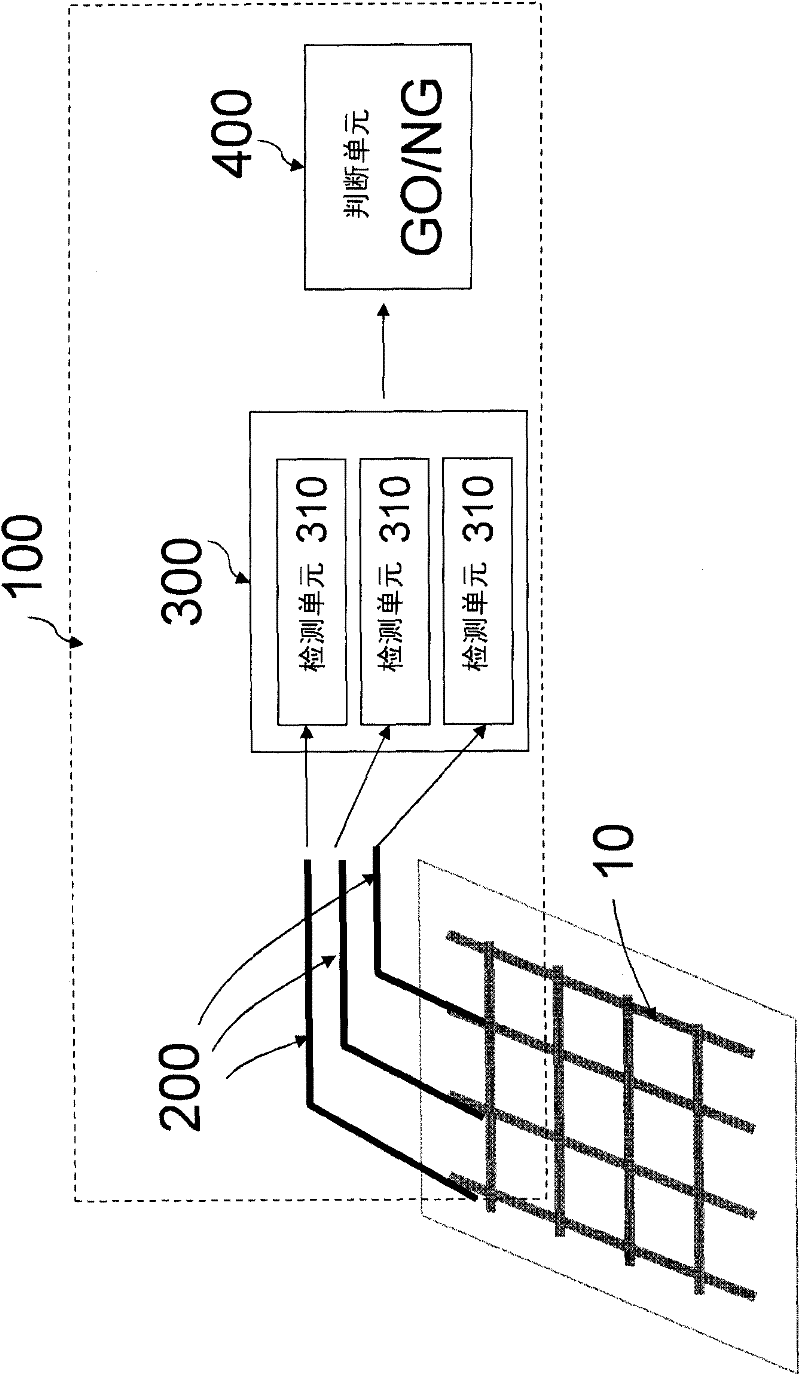

[0019] An embodiment of the present invention discloses a testing device 100 . image 3 A schematic diagram of a testing device 100 according to an embodiment of the present invention is shown. The testing device 100 includes a plurality of sensors 200 , a detection module 300 and a judgment module 400 .

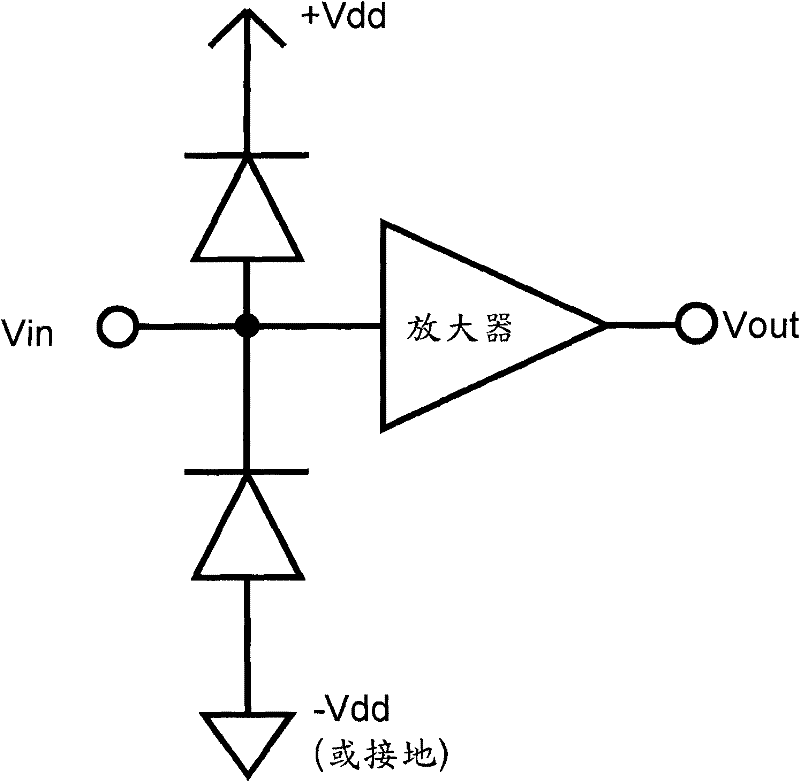

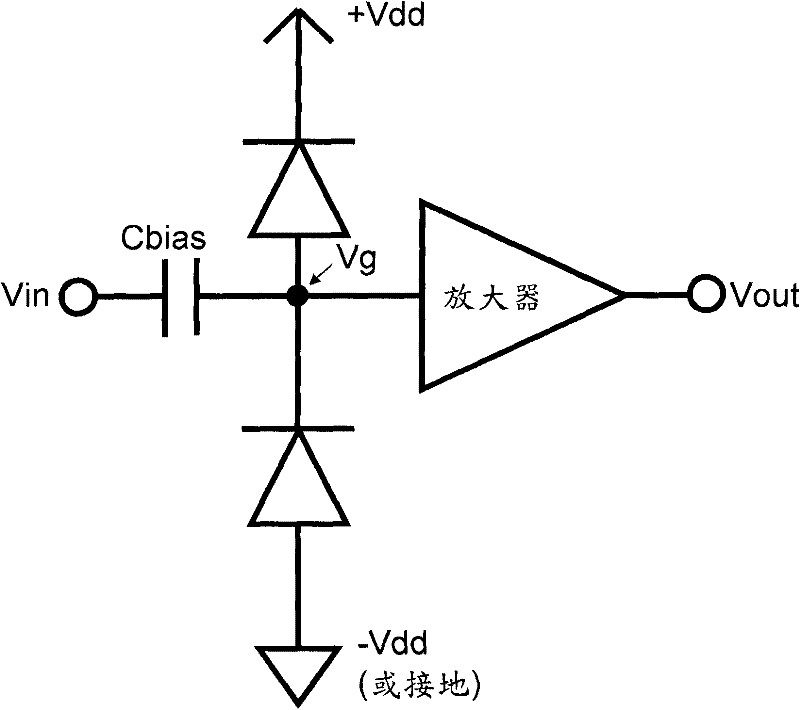

[0020] The sensors 200 are used for sensing a plurality of tiny capacitive signals Vin of the object under test 10 (touch panel). It should be noted that in order to simplify the complexity of the description, the sensor 200 in the diagram is drawn with a simple line segment, and those skilled in the art should be able to understand it according to the diagram and description, and implement it using various sensors that are currently available or will be developed in the future . The detection module 300 receives and processes the plurality of tiny capacitance signals Vin to generate a plural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com