Method and system for simply and efficiently injecting mercury into ultrahigh-voltage capillary tubular mercury lamp

A capillary, ultra-high pressure technology, applied in the direction of electric tube/lamp exhaust, electric tube/lamp filling, etc., can solve the problems of mercury injection error, easy confusion, time-consuming and laborious, and achieve the effect of solving the cumbersome process and simplifying the operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

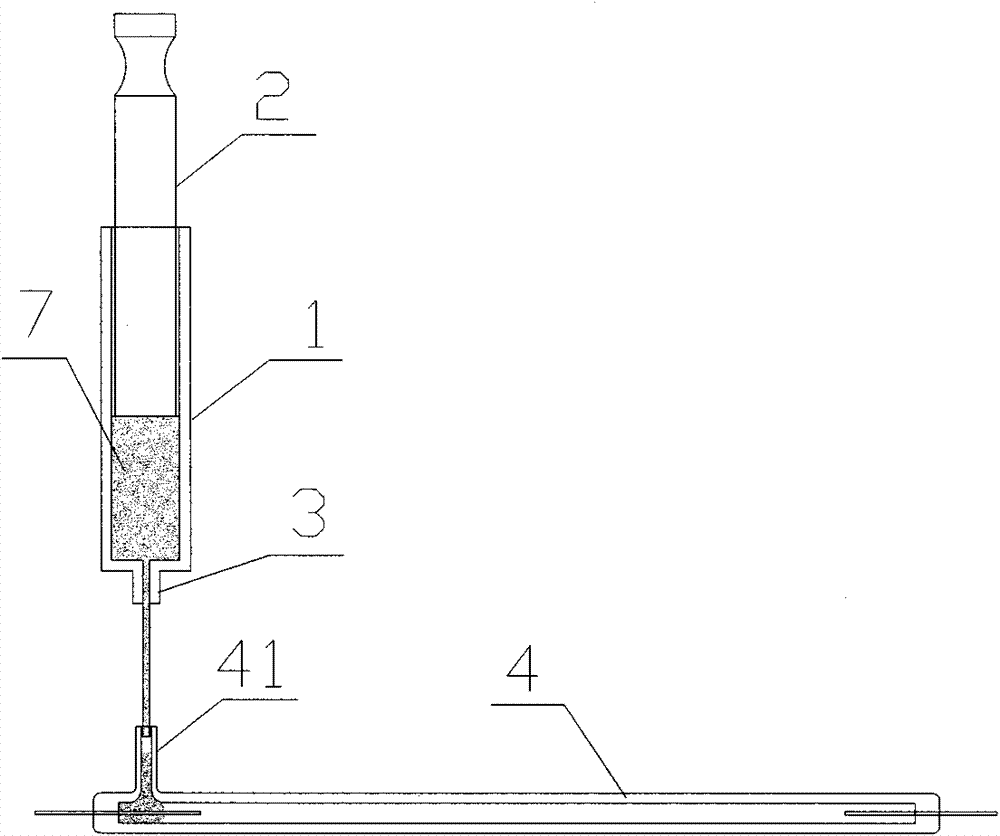

[0034] The preferred embodiments of the present invention will be described in detail below with reference to the drawings.

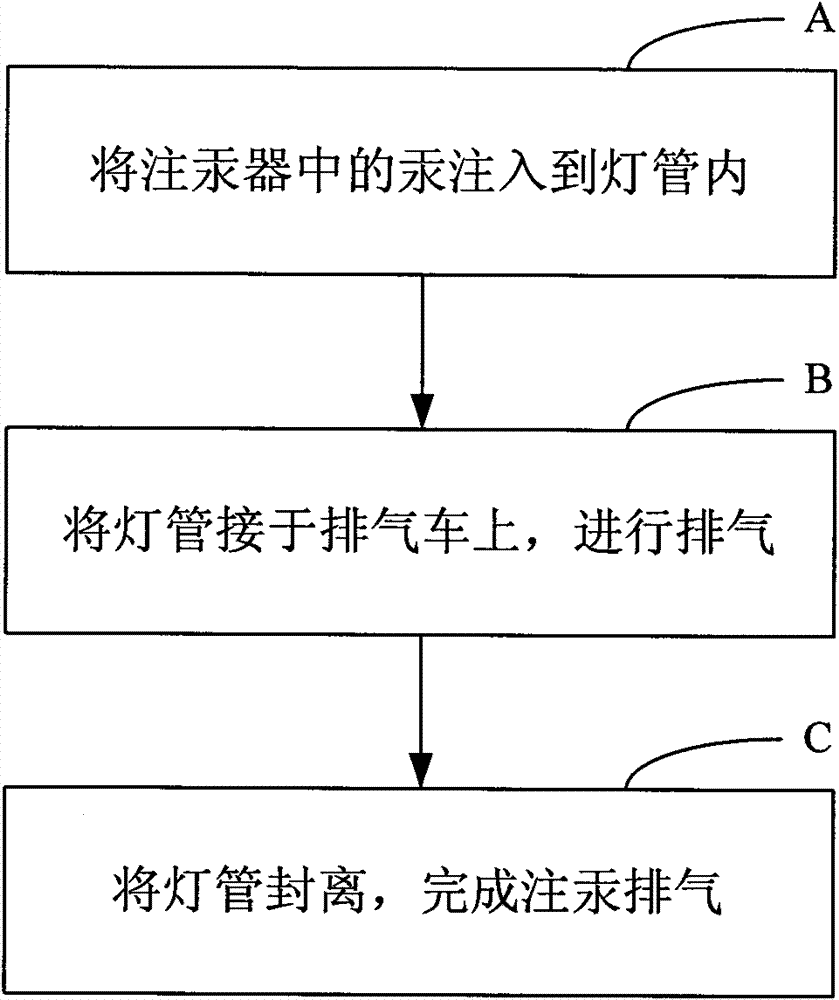

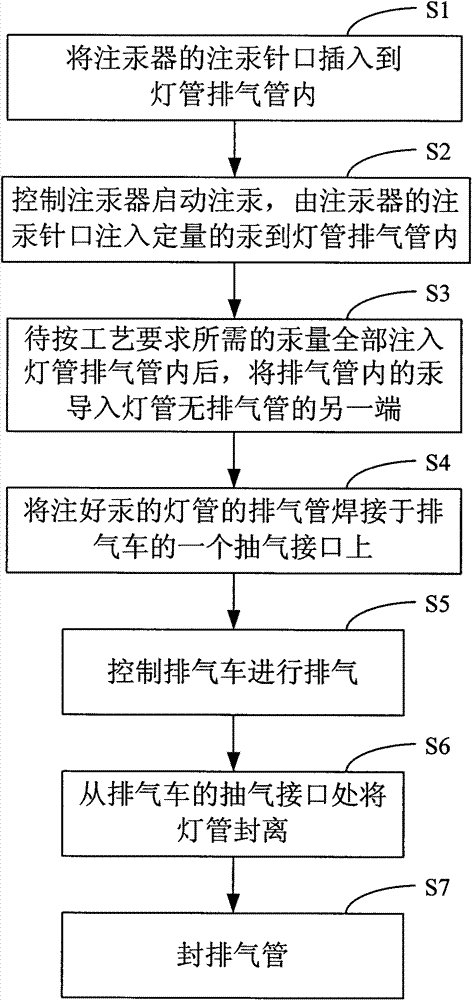

[0035] Such as figure 1 It is a flow chart of the method for injecting mercury into an ultra-high pressure capillary mercury lamp provided by the present invention. The mercury injection method comprises the following steps:

[0036] Step A: Inject the mercury in the mercury injector into the lamp tube;

[0037] In terms of specific implementation of this step, a certain amount of mercury is loaded into the mercury injector in advance, the mercury in the mercury injector is injected into the exhaust pipe of the lamp tube, and finally the mercury in the exhaust pipe is introduced into the lamp tube without exhaust pipe the other end.

[0038] Step B: Connect the lamp tube to the exhaust car to exhaust;

[0039] In terms of specific realization of this step, firstly, the mercury-injected lamp tube is welded to an air extraction interface of the exhaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com