Screwdriver of ratchet mechanism

A ratchet mechanism and screwdriver technology, applied to screwdrivers, manufacturing tools, etc., can solve problems such as difficult control of the direction, large size, complicated assembly and production steps, etc., and achieve the effect of loosening and loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

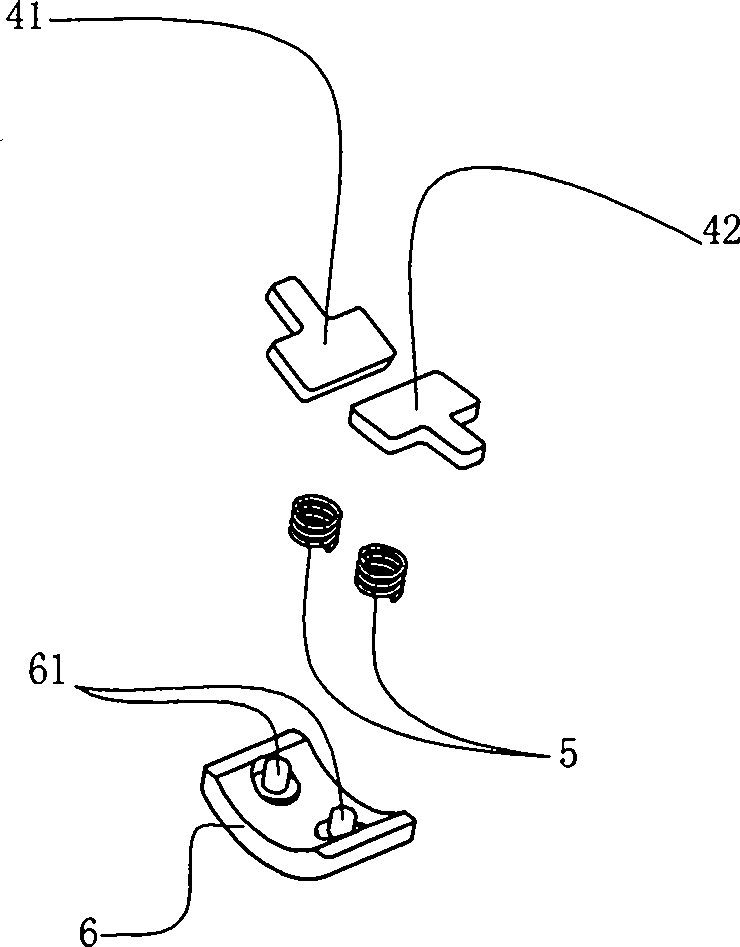

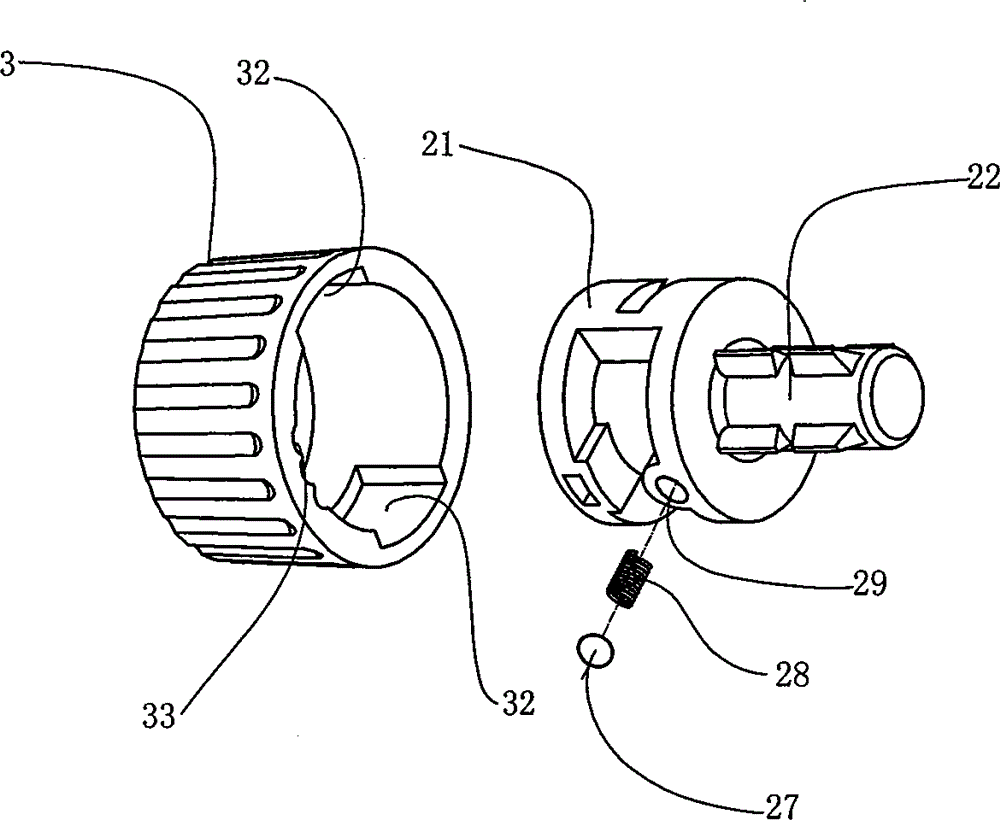

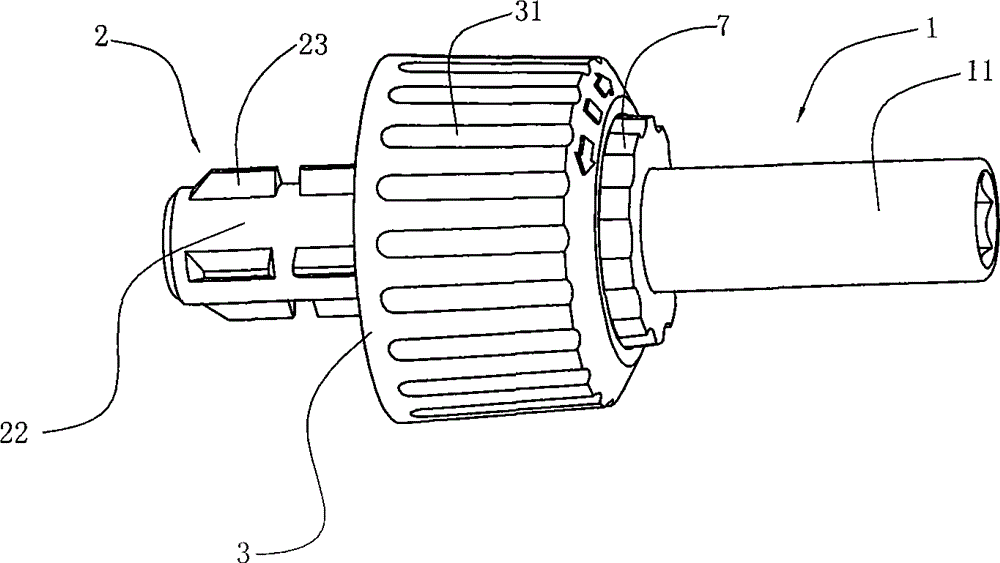

[0018] figure 1 It is a three-dimensional view of the screwdriver of the present invention. The screwdriver in this figure has been assembled, including the front rod 1 and the rear rod 2, as well as the rotating sleeve 3 on the rear rod 2 and the fixed sleeve 7 between the front rod 1 and the rear rod 2 . figure 2 It is a three-dimensional exploded view of the screwdriver of the present invention. As shown in the figure, the front rod 1 includes a cavity 11 at the front for fixedly connecting the screwdriver bit and a central gear 12 at the rear of the cavity 11. The cavity 11 It can be used to connect different types of screwdriver bits to tighten or loosen various types of screws. The rear rod 2 includes a connecting part 22 and a base part 21. The front end of the base part 21 has a thread 24, and the base part The diameter of 21 is lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com