Construction method for tuyere

A construction method and the technology of tuyere sleeves, which are applied in the field of tuyere sleeve installation and construction, can solve problems such as many unsafe factors in man-machine cooperation, untimely information transmission, and high labor intensity of workers, so as to reduce construction risks, save manpower and material resources, shorten The effect of the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

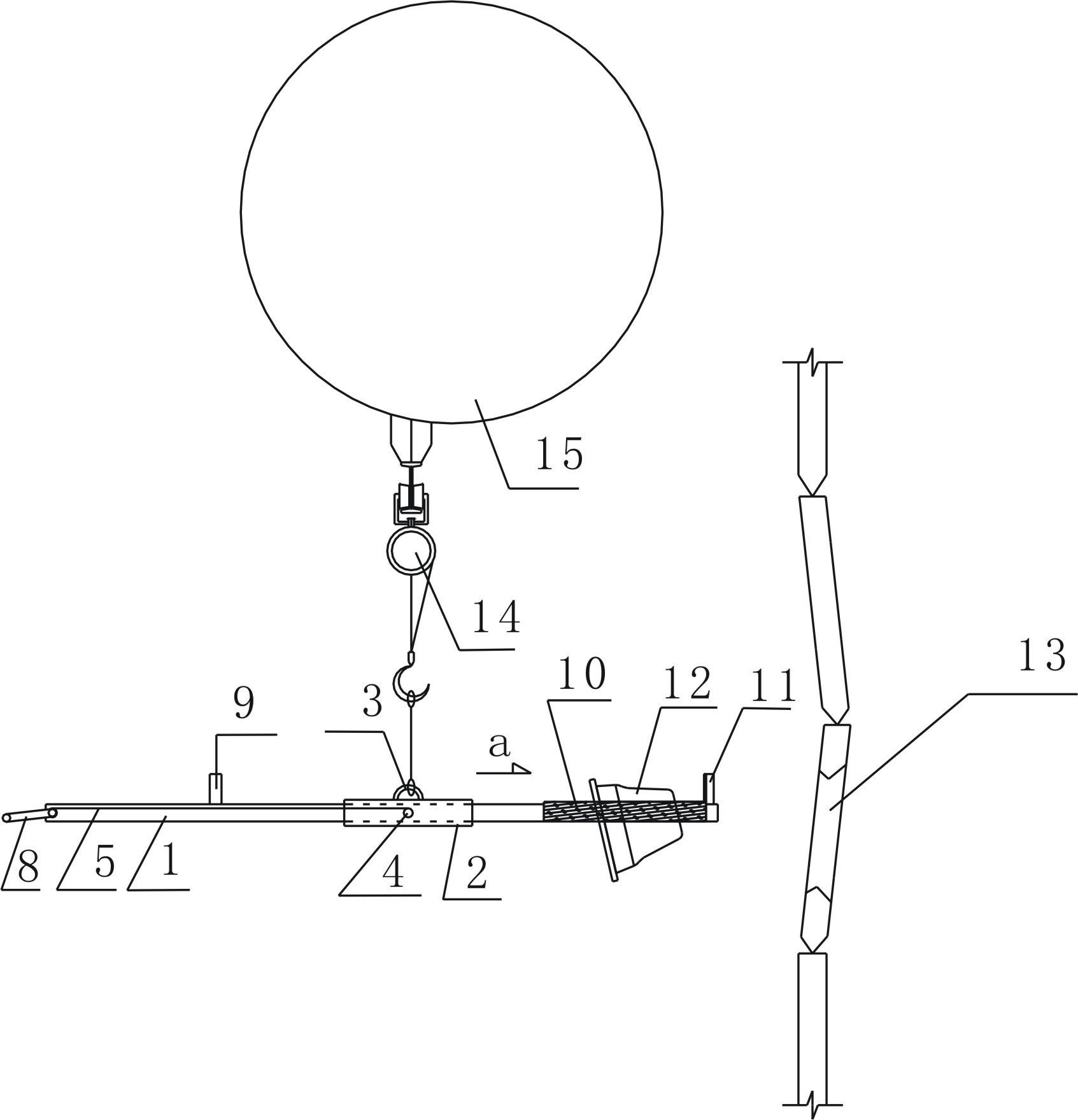

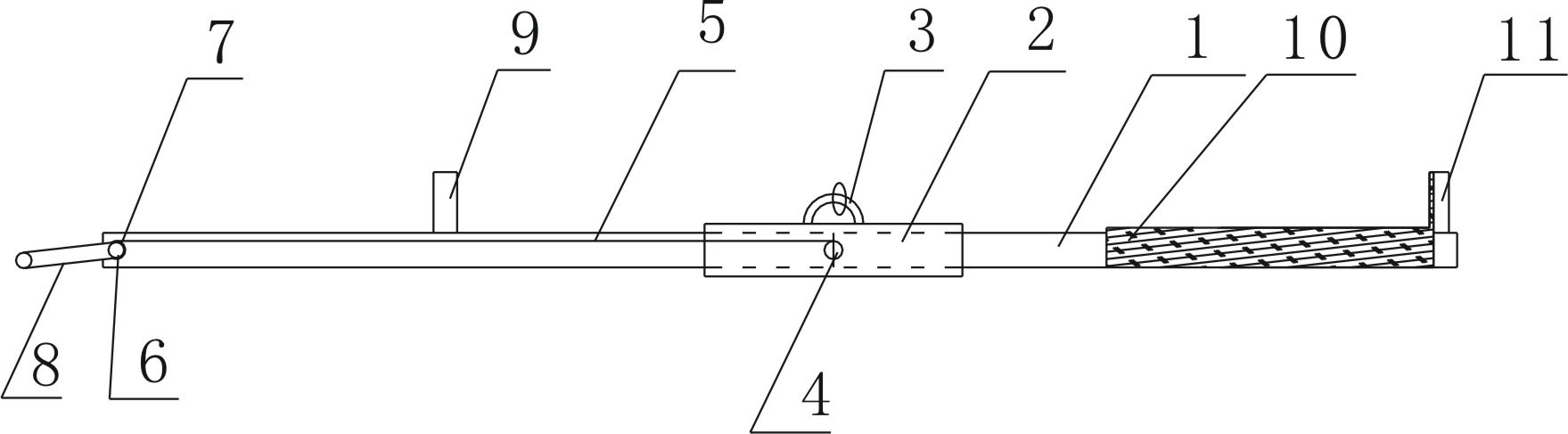

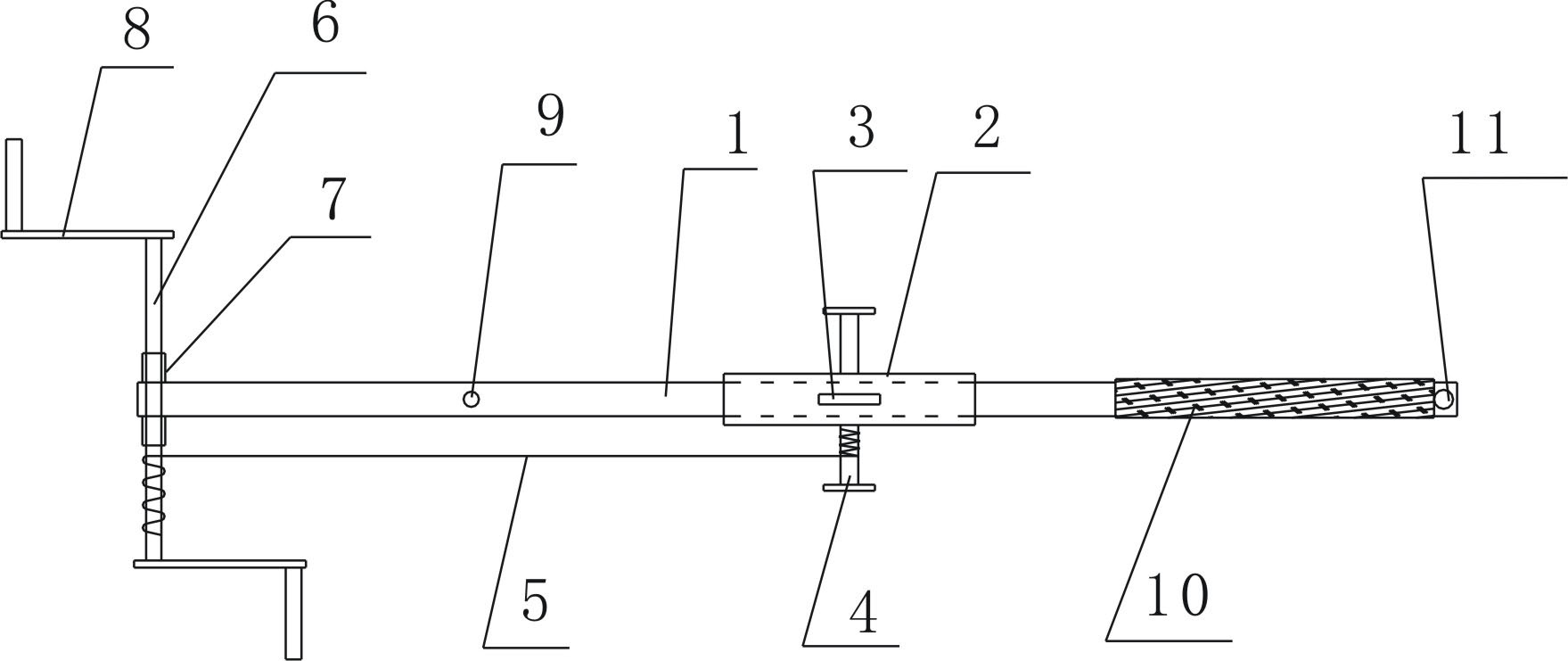

[0021] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0022] see figure 1 , figure 2 and image 3 , a kind of tuyere cover installation construction method comprises the following steps:

[0023] Step (1), respectively mark the cross center line on the tuyere sleeve 12 and the tuyere 13 of the ironmaking blast furnace;

[0024] Step (2), put the tuyere cover 12 in the step (1) on the lever for installation and construction of the tuyere cover, lift it to the vicinity of the center line of the tuyere 13 of the ironmaking blast furnace, and then adjust the center line of the tuyere cover 12 to be in line with the smelting furnace. The centerlines of the tuyeres 13 of the iron blast furnace coincide;

[0025] Step (3), push the tuyere cover 12 forward to the installation position with the lever for the installation and construction of the tuyere cover in step (2), and always ensure that the concentricity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com