Radiator structure

A technology for radiators and heat dissipation parts, which is applied in the fields of instrumentation, cooling/ventilation/heating transformation, electrical digital data processing, etc. It can solve the problems of low heat dissipation performance, heavy weight, and high cost, and achieve convenient combination, flexible design, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

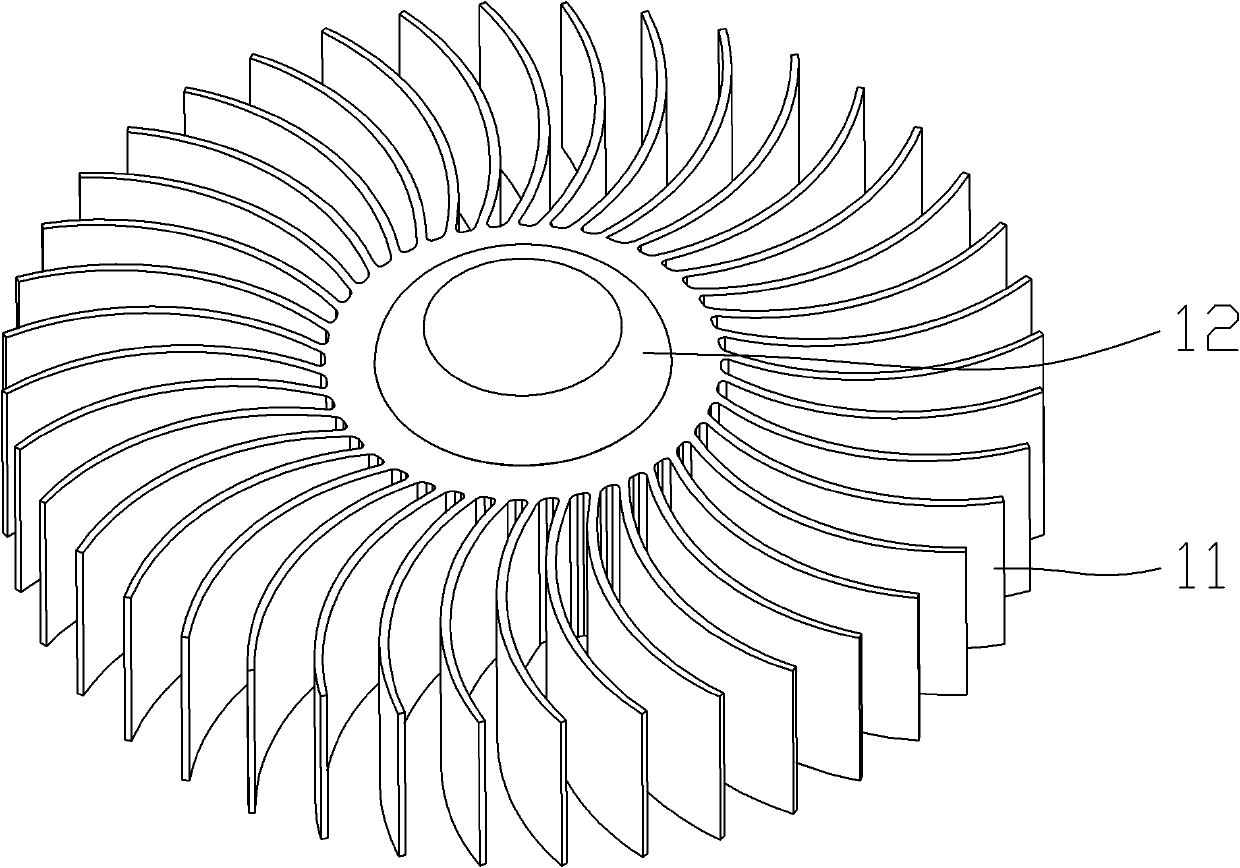

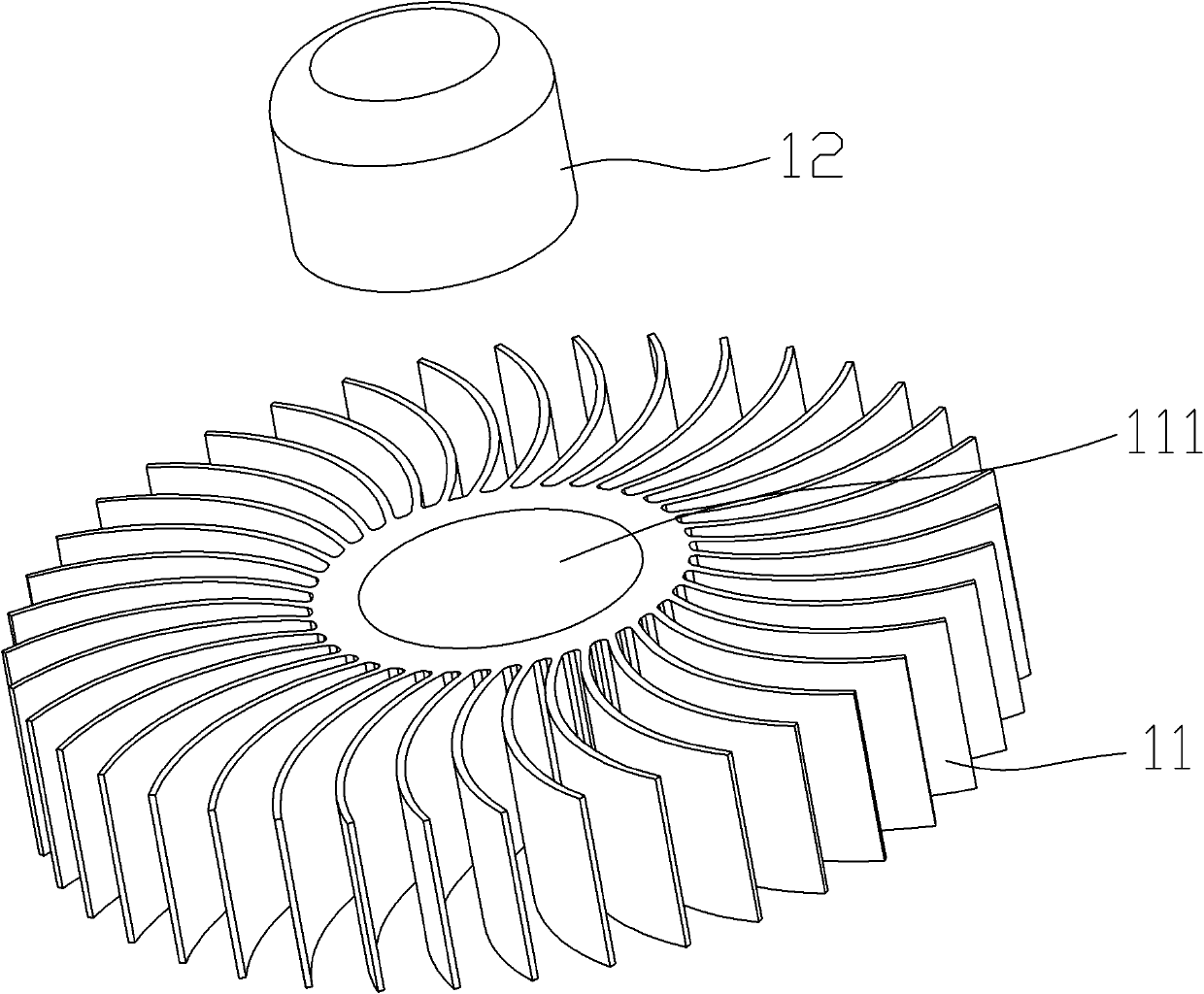

[0027] refer to image 3 , Figure 4 and Figure 5 As shown, they are respectively the overall schematic diagram and the exploded schematic diagram of the radiator structure of the present invention.

[0028] Radiator structure of the present invention, it comprises:

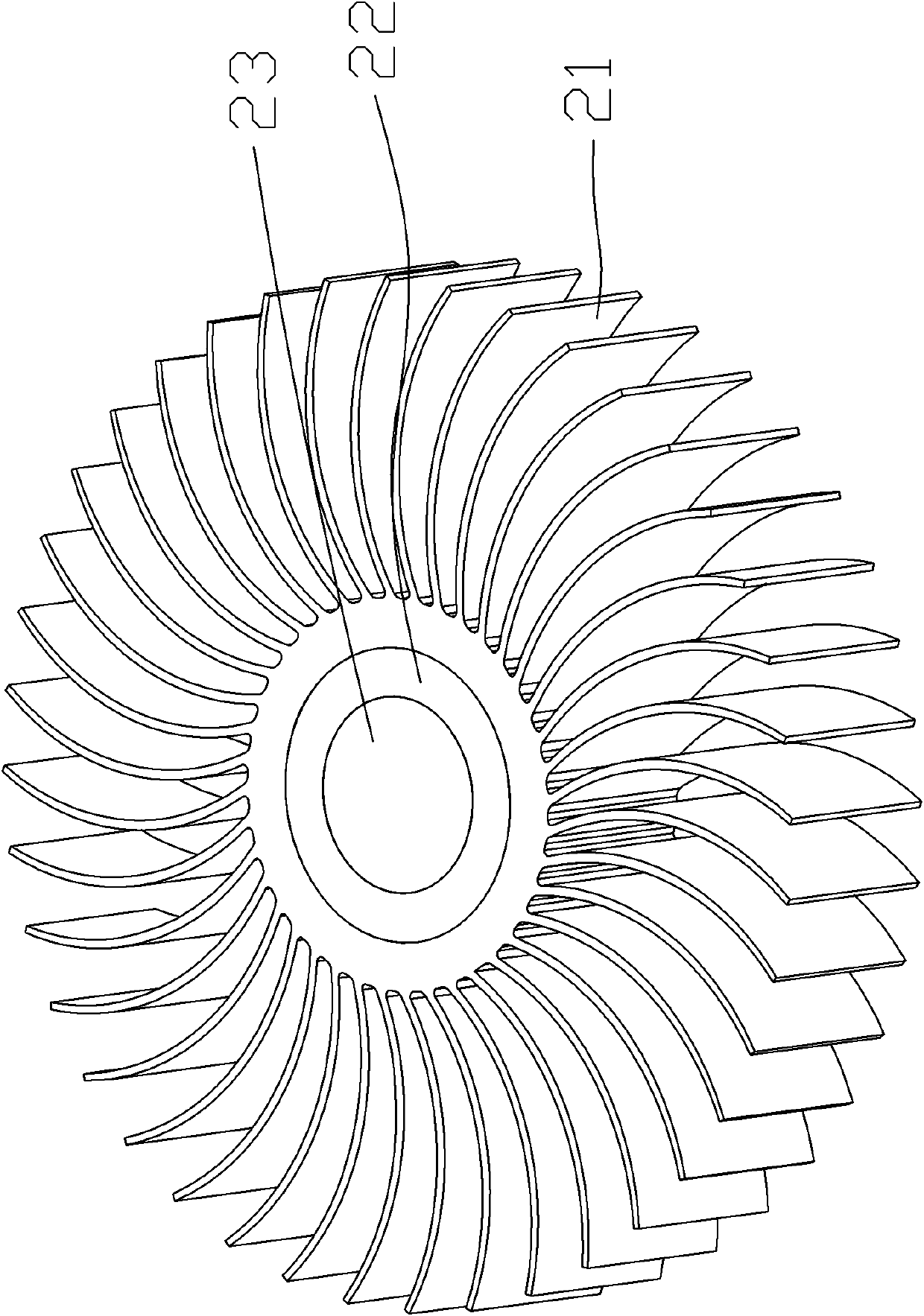

[0029] The heat dissipation fins 21 are provided with an opening 211 in the middle position. In this embodiment, the heat dissipation fins 21 are distributed in a circular shape. The heat dissipation fins 21 are flexible in design, and can be designed according to actual needs in other embodiments. Different shapes, such as: rectangular distribution;

[0030] The first heat dissipation portion 22 is disposed in the opening 211 and completely contacts with each other. The first heat dissipation portion 22 is provided with a groove 221, and the bottom of the groove 221 is in contact with a heat source 20 to conduct heat conduction, and The first heat dissipation part 22 is made of copper;

[0031] The second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com